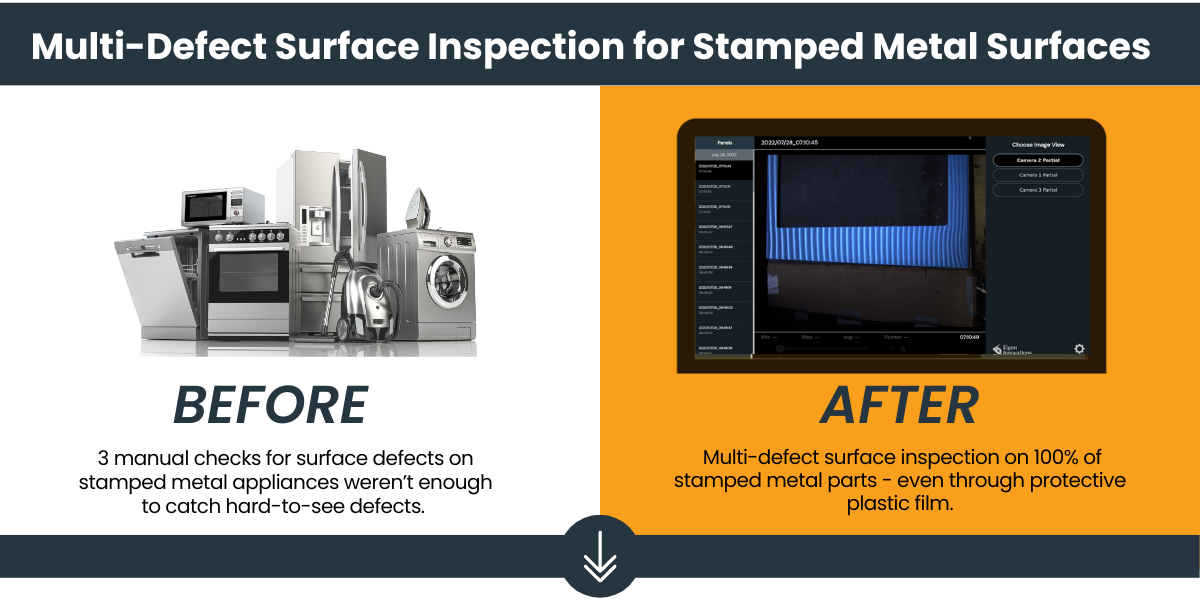

Industry: Metal Manufacturing (Stamping) | Headquarters: USA | Employees: 100+

Henderson Stamping is an international stamping supplier in a 100,000-square-foot facility. Top manufacturers – including leading home appliance brands – rely on the Henderson plant for powder coating and medium- to high-volume stampings. The company continually procures the latest computerized systems, machining and measuring equipment and robotics.