AI-Powered

Thermal Vision

AI-Powered

Thermal Vision

Helping leading manufacturers eliminate risk and maximize quality throughout.

Helping leading manufacturers eliminate risk and maximize quality throughout.

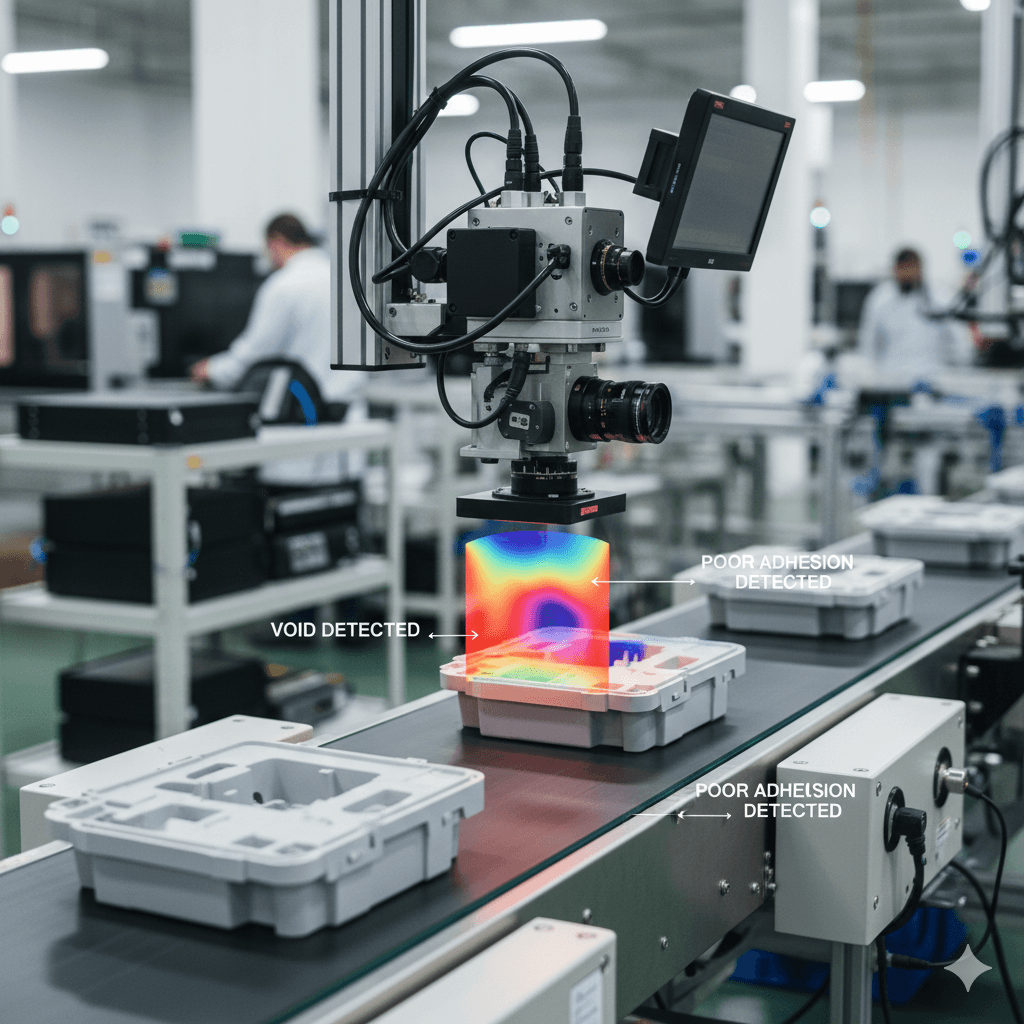

Eigen's AI thermal vision solutions solve difficult quality inspection and condition monitoring tasks where traditional rules-based machine vision struggles.

Eigen's AI thermal vision solutions solve difficult quality inspection and condition monitoring tasks where traditional rules-based machine vision struggles.

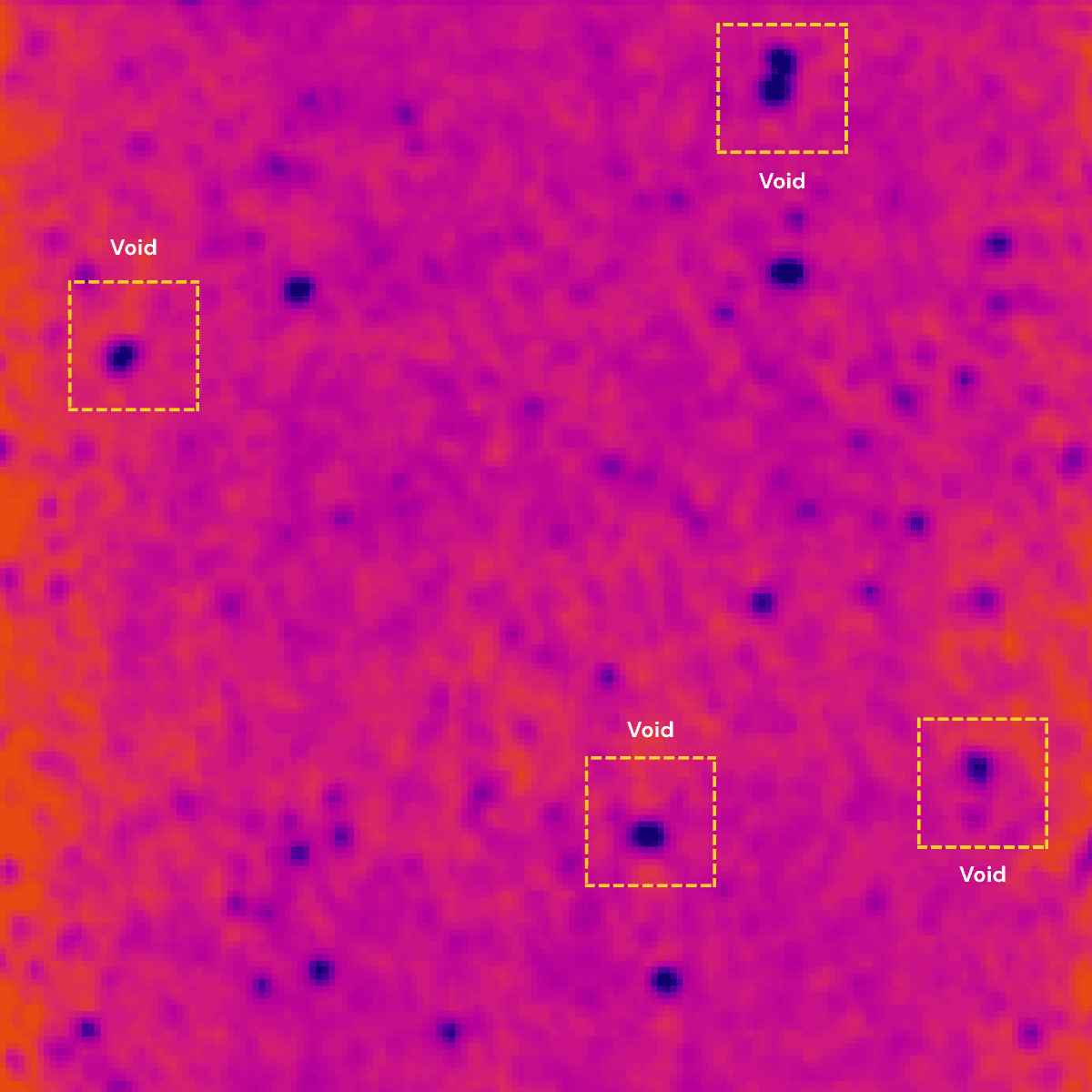

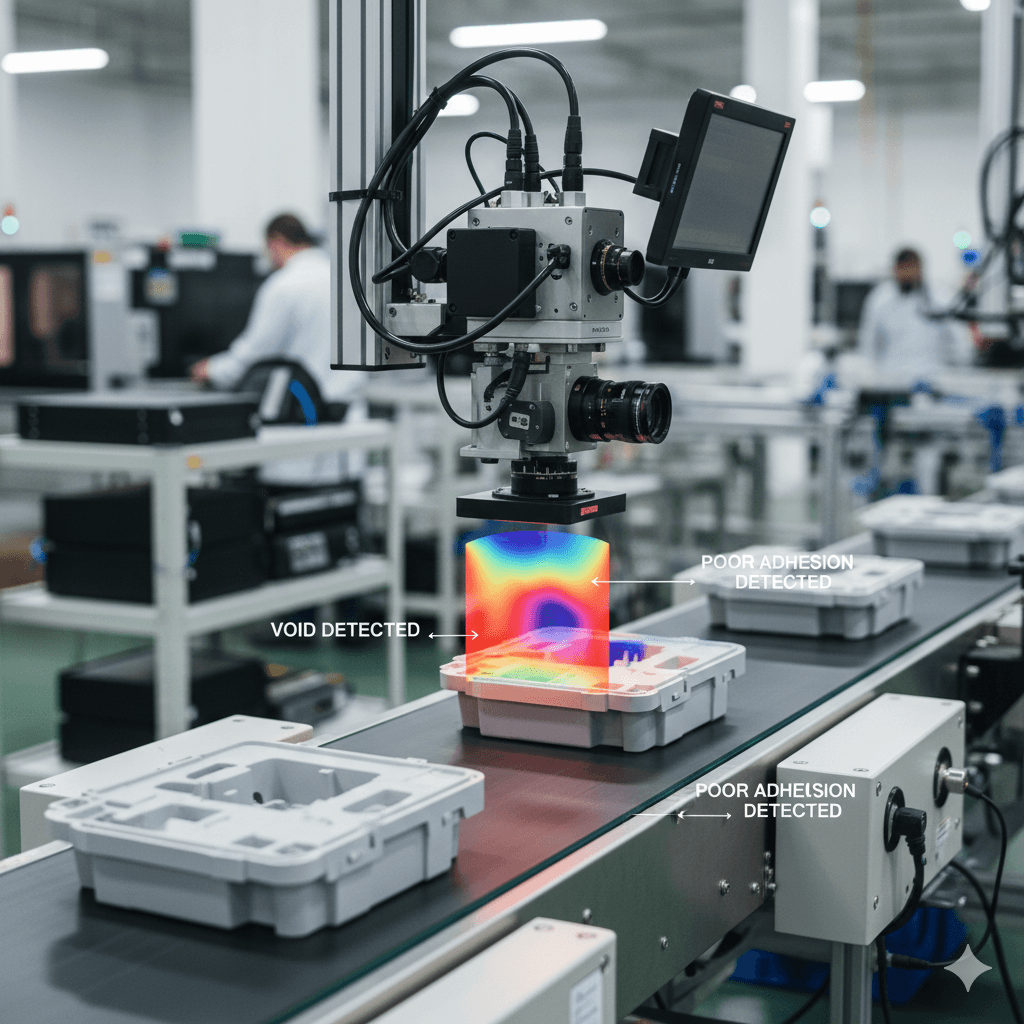

Most defects and equipment failures show up in thermal patterns before they show up anywhere else. We apply AI thermal vision to the two problems where it matters most.

Most defects and equipment failures show up in thermal patterns before they show up anywhere else. We apply AI thermal vision to the two problems where it matters most.

01

AI Thermal Quality Inspection

AI Thermal Quality Inspection

Detect defects in products that traditional vision misses: voids, adhesion issues, and material inconsistencies. Using thermal patterns and AI that learns from variation. Catch issues earlier, reduce scrap and rework, and get process data that wasn't possible before.

02

AI Thermal Condition Monitoring

AI Thermal Condition Monitoring

Track equipment and process temperatures continuously. Catch anomalies before they cause downtime or quality issues. Less unplanned downtime, fewer manual checks, and visibility you couldn't get with spot inspections.

Thermal + AI

Thermal + AI

Threshold-based machine vision works until conditions change. Thermal + AI is what makes Eigen different. Thermal patterns reveal what surface inspection can't, and AI handles the variation.

Threshold-based machine vision works until conditions change. Thermal + AI is what makes Eigen different. Thermal patterns reveal what surface inspection can't, and AI handles the variation.

Threshold-based machine vision works until conditions change. Thermal + AI is what makes Eigen different. Thermal patterns reveal what surface inspection can't, and AI handles the variation.

Traditional Machine Vision

Breaks when products or processes vary

Requires constant rule tuning

Breaks when products or processes vary

Requires constant rule tuning

Breaks when products or processes vary

Requires constant rule tuning

Eigen Innovations

AI learns from variation and adapts

Models improve over time, with less maintenance

AI learns from variation and adapts

Models improve over time, with less maintenance

Plastics

Metals

Adhesives

Building Materials

Food and Beverages

Plastics covers high-stakes processes like injection molding, thermoforming, and blow molding. Eigen’s AI uses thermal imaging to detect "hidden" defects like short-shots, flash, and internal voids, ensuring 100% inline quality verification.

Solutions

Description

Plastics

Metals

Adhesives

Building Materials

Food and Beverages

Plastics covers high-stakes processes like injection molding, thermoforming, and blow molding. Eigen’s AI uses thermal imaging to detect "hidden" defects like short-shots, flash, and internal voids, ensuring 100% inline quality verification.

Plastics

Metals

Adhesives

Building Materials

Food and Beverages

Plastics covers high-stakes processes like injection molding, thermoforming, and blow molding. Eigen’s AI uses thermal imaging to detect "hidden" defects like short-shots, flash, and internal voids, ensuring 100% inline quality verification.

Get started with

OneView

today

Contact

Contact us for more information & get started

Copyright © 2025 Eigen Innovations.

All Rights Reserved.