In-Line Thermal Inspection Made Easy

Industry-Leading Hardware Partners

We work closely with industry-leading industrial PC and camera OEMs to ensure the highest reliability and quality results.

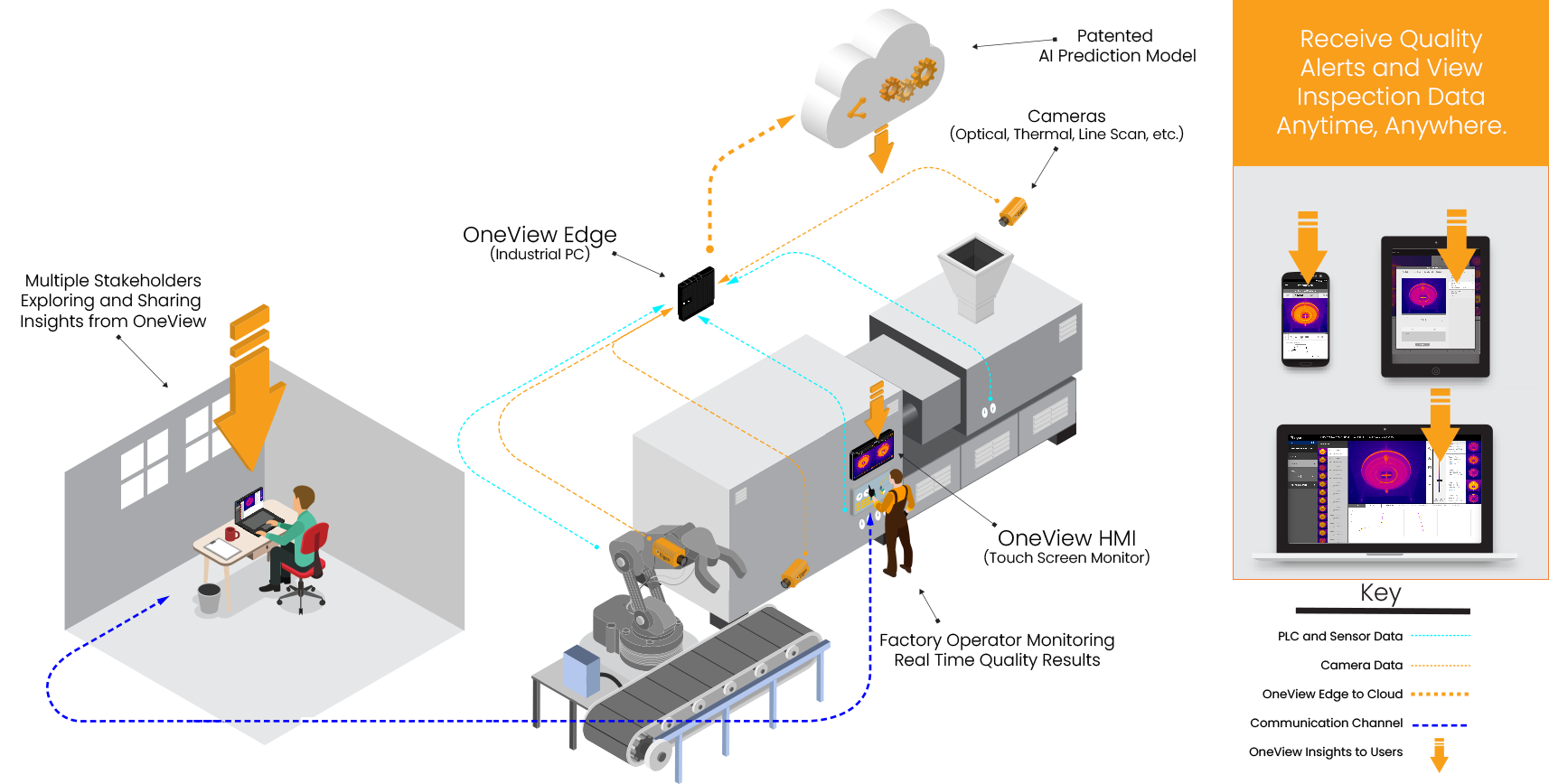

How Our Solutions Work

Key Features

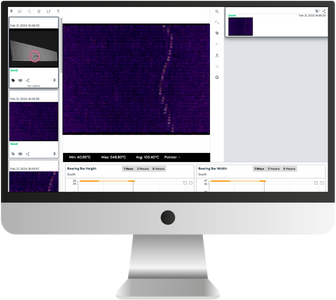

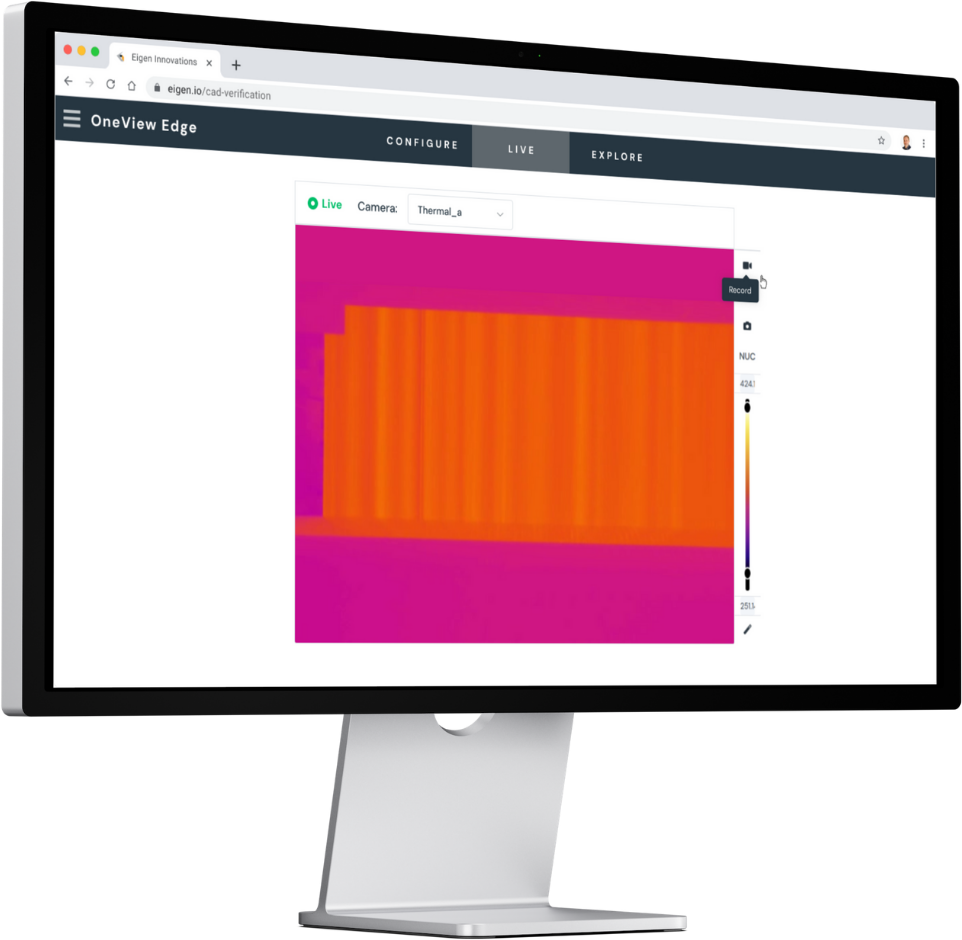

- Integrate with industry-leading infrared cameras for no-contact temperature measurement.

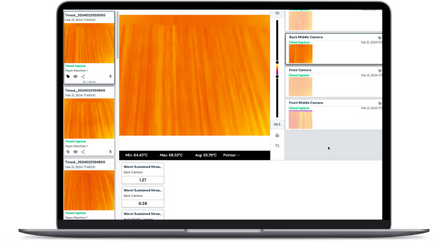

- Touch-screen HMI with an easy-to-use, intuitive interface that allows operators to view quality results and train AI models with no code. (optional)

- No-code configuration tool allows for complex interactions and vision system control with no integrator or programming experience required.

- Out-of-the-box integration with PLCs and other industrial protocols allow for bidirectional communication and automation based on quality inspection results.

- APIs make it easy to integrate OneView with other industrial applications and tools.

One-View Edge runs in-factory to ensure 100% part inspection and automation on the fastest manufacturing processes.

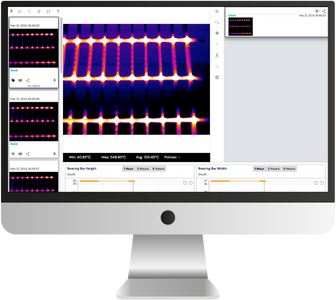

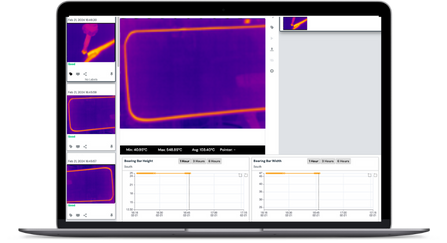

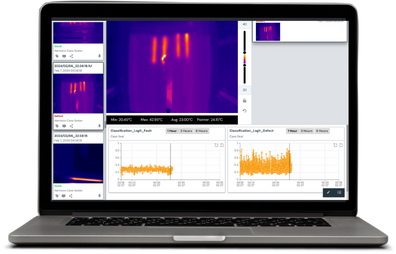

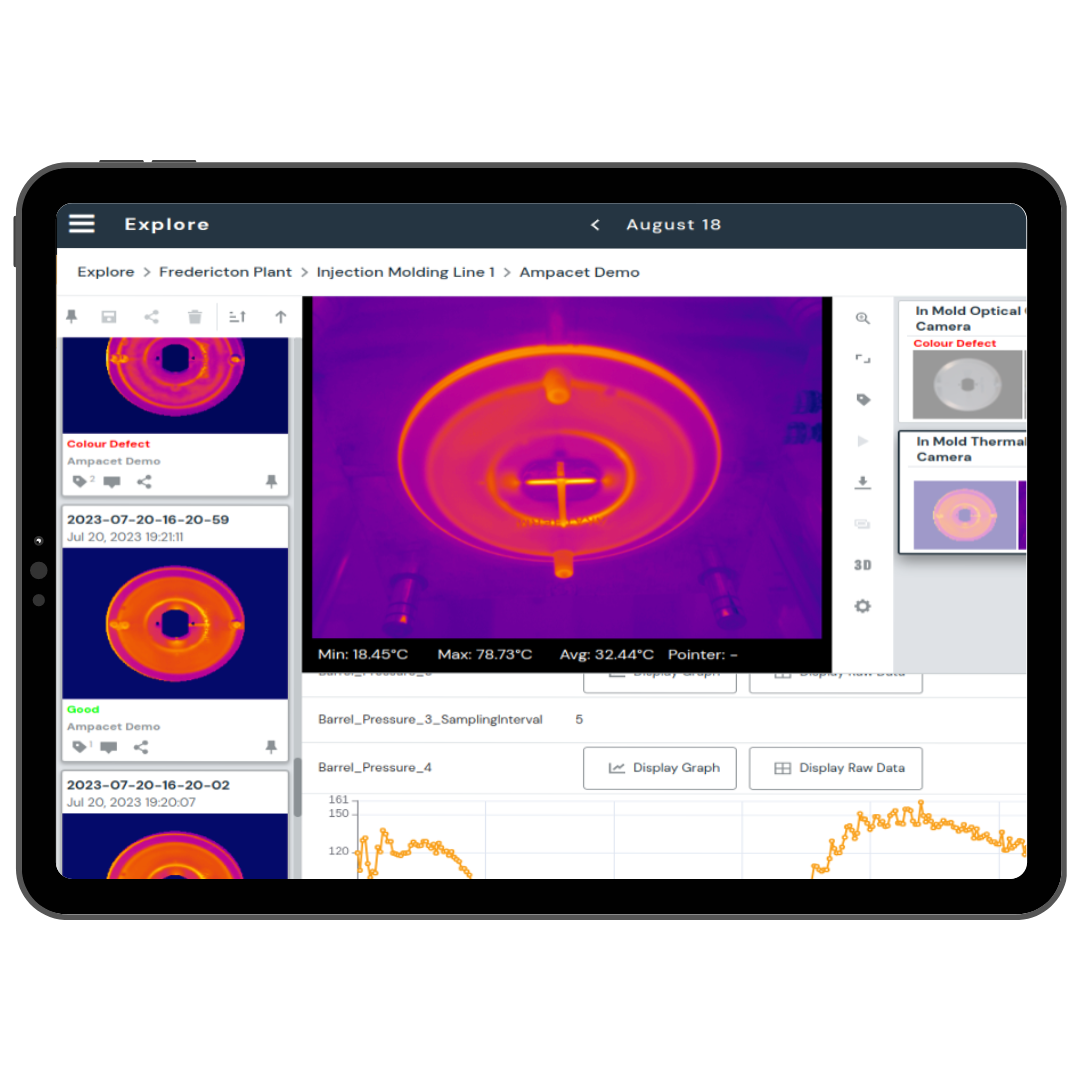

OneView’s HMI (human machine interface) is a touch-screen monitor that allows machine operators and engineers to view real-time quality results, see historical inspection data and even build AI models in an easy-to-use no code interface.

OneView supports GigE Vision and GenICam compliant sensors and cameras. That means you can avoid vendor lock-in and finally use a single quality application across thermal, optical, laser, line scan and other types of inspection processes.

OneView natively supports bidirectional communication with PLCs and other industrial protocols, including OPC-UA and Modbus, making it easy to preform closed-loop automation based on quality results.

OneView allows stakeholders to easily view historical inspection data, real-time camera feeds and process insights. Best of all, they can do this anytime, anywhere.

Step 1

Connect the Hardware

Plug and play components make it simple to get started quickly.

Step 2

Configure the Application

A no-code installation and configuration experience simplifies the process.

Start Automating Your Thermal Inspections Today

Are you ready to experience OneView?

Get Started TodayGet Started Today