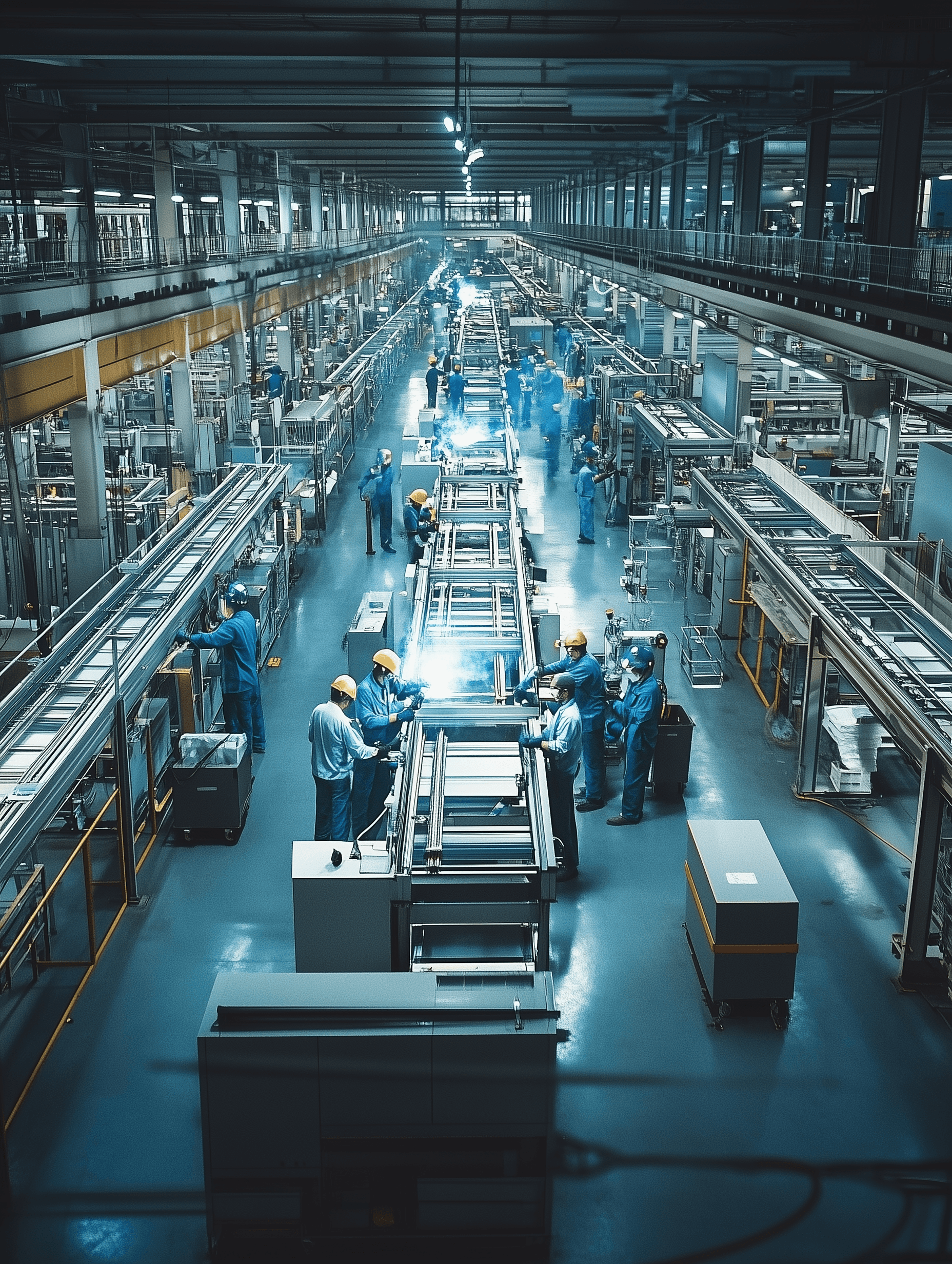

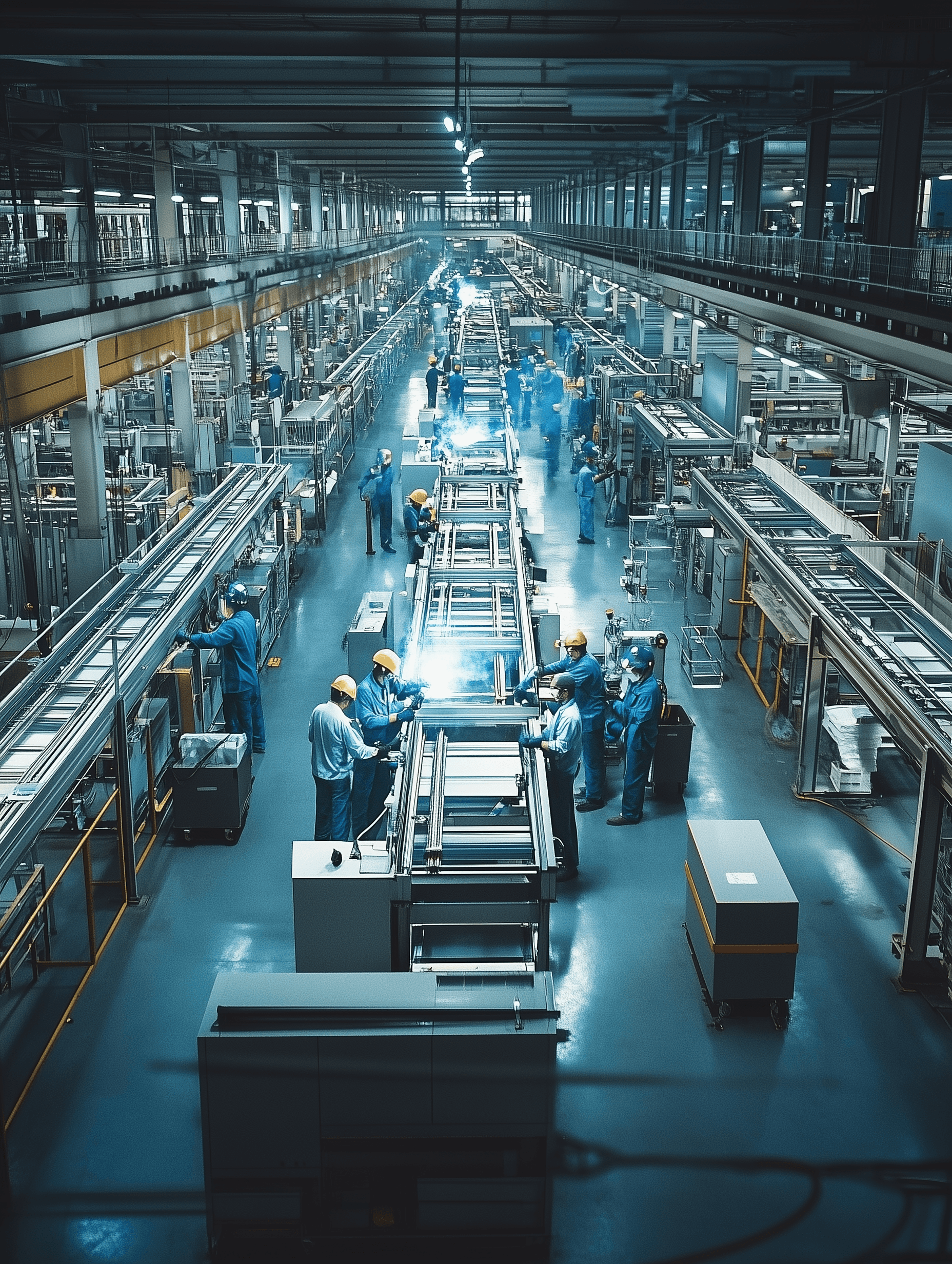

AI Powered Vision

Seeing Beyond Defects

AI Powered Vision

Seeing Beyond Defects

Eigen combines thermal imaging and AI to detect issues traditional vision systems miss, revolutionizing quality inspection.

Eigen combines thermal imaging and AI to detect issues traditional vision systems miss, revolutionizing quality inspection.

AI Vision Today

How Eigen Solves for It

How We’re Different

Expert Dependence

AI vision solutions require specialized data science teams to implement and maintain.

Scalability Barrier

Solutions force manufacturers to choose application-specific tools that don't scale.

Workflow Gaps

Solutions force manufacturers to choose generic platforms missing critical workflow components.

Delayed Returns

The time required to achieve ROI can be extensive.

AI Vision Today

How Eigen Solves for It

How We’re Different

Expert Dependence

AI vision solutions require specialized data science teams to implement and maintain.

Scalability Barrier

Solutions force manufacturers to choose application-specific tools that don't scale.

Workflow Gaps

Solutions force manufacturers to choose generic platforms missing critical workflow components.

Delayed Returns

The time required to achieve ROI can be extensive.

AI Vision Today

How Eigen Solves for It

How We’re Different

Expert Dependence

AI vision solutions require specialized data science teams to implement and maintain.

Scalability Barrier

Solutions force manufacturers to choose application-specific tools that don't scale.

Workflow Gaps

Solutions force manufacturers to choose generic platforms missing critical workflow components.

Delayed Returns

The time required to achieve ROI can be extensive.

Over

2.5 Billion

Quality Metrics Analysed

Over

1 Billion

Images Processsed Daily

Over

180,000

Events Monitored Daily

Over

29,000

Parts Verified Everyday

Over

2.5 Billion

Quality Metrics Analysed

Over

1 Billion

Images Processsed Daily

Over

180,000

Events Monitored Daily

Over

29,000

Parts Verified Everyday

OneView eliminates tradeoffs in vision AI implementation, providing a complete end-to-end platform for design, deployment, monitoring, and management—requiring no specialized expertise while transforming a high-risk, high-cost initiative into a scalable, value-driven solution.

OneView | Cloud

OneView | Cloud + Edge

Key Features:

•

Anomaly Detection

•

No-Code AI Model Training

•

Prediction Heatmaps

•

Data Consolidation & Searchability

•

Image / Data Ingestion

•

Automated Quality & Anomaly Reports

•

Find & Contain Similar Defects

•

Explainable AI Predictions

OneView eliminates tradeoffs in vision AI implementation, providing a complete end-to-end platform for design, deployment, monitoring, and management—requiring no specialized expertise while transforming a high-risk, high-cost initiative into a scalable, value-driven solution.

OneView | Cloud

OneView | Cloud + Edge

Key Features:

•

Anomaly Detection

•

No-Code AI Model Training

•

Prediction Heatmaps

•

Data Consolidation & Searchability

•

Image / Data Ingestion

•

Automated Quality & Anomaly Reports

•

Find & Contain Similar Defects

•

Explainable AI Predictions

OneView eliminates tradeoffs in vision AI implementation, providing a complete end-to-end platform for design, deployment, monitoring, and management—requiring no specialized expertise while transforming a high-risk, high-cost initiative into a scalable, value-driven solution.

OneView | Cloud

OneView | Cloud + Edge

Key Features:

•

Anomaly Detection

•

No-Code AI Model Training

•

Prediction Heatmaps

•

Data Consolidation & Searchability

•

Image / Data Ingestion

•

Automated Quality & Anomaly Reports

•

Find & Contain Similar Defects

•

Explainable AI Predictions

Thermal Vision Applications

Thermal Vision Applications

Eigen specializes in combining thermal imaging with advanced AI to detect issues that traditional systems miss, enabling a new era of quality inspection for heat-critical manufacturing processes

Eigen specializes in combining thermal imaging with advanced AI to detect issues that traditional systems miss, enabling a new era of quality inspection for heat-critical manufacturing processes

[4]

[3]

[2]

[1]

[5]

Adhesive

Application

Drywall

Manufacturing

Speciality Paper

Manufacturing

Metal

Welding

Plastic

Welding

Packaging

& Adhesives

Metals

Plastics

Building

Materials

[4]

[3]

[2]

[1]

[5]

[4]

[3]

[2]

[1]

[5]

[4]

[3]

[2]

[1]

[5]

[4]

[3]

[2]

[1]

[5]

[4]

[3]

[2]

[1]

[5]

Problem Manufacturers rely on sample destructive testing to ensure weld integrity. Solution Thermal cameras capture multiple views of the weld process, and our AI predicts weld quality in real-time.

[4]

[3]

[2]

[1]

[5]

Adhesive

Application

Drywall

Manufacturing

Speciality Paper

Manufacturing

Metal

Welding

Plastic

Welding

Packaging

& Adhesives

Metals

Plastics

Building

Materials

[4]

[3]

[2]

[1]

[5]

[4]

[3]

[2]

[1]

[5]

[4]

[3]

[2]

[1]

[5]

[4]

[3]

[2]

[1]

[5]

[4]

[3]

[2]

[1]

[5]

Problem Manufacturers rely on sample destructive testing to ensure weld integrity. Solution Thermal cameras capture multiple views of the weld process, and our AI predicts weld quality in real-time.

[4]

[3]

[2]

[1]

[5]

Adhesive

Application

Drywall

Manufacturing

Speciality Paper

Manufacturing

Metal

Welding

Plastic

Welding

Packaging

& Adhesives

Metals

Plastics

Building

Materials

[4]

[3]

[2]

[1]

[5]

[4]

[3]

[2]

[1]

[5]

[4]

[3]

[2]

[1]

[5]

[4]

[3]

[2]

[1]

[5]

[4]

[3]

[2]

[1]

[5]

Problem Manufacturers rely on sample destructive testing to ensure weld integrity. Solution Thermal cameras capture multiple views of the weld process, and our AI predicts weld quality in real-time.

Over

2.5 Billion

Quality Metrics Analysed

Over

1 Billion

Images Processsed Daily

Over

180,000

Events Monitored Daily

Over

29,000

Parts Verified Everyday

Over

2.5 Billion

Quality Metrics Analysed

Over

1 Billion

Images Processsed Daily

Over

180,000

Events Monitored Daily

Over

29,000

Parts Verified Everyday

Explore

Case Studies

Explore

Case Studies

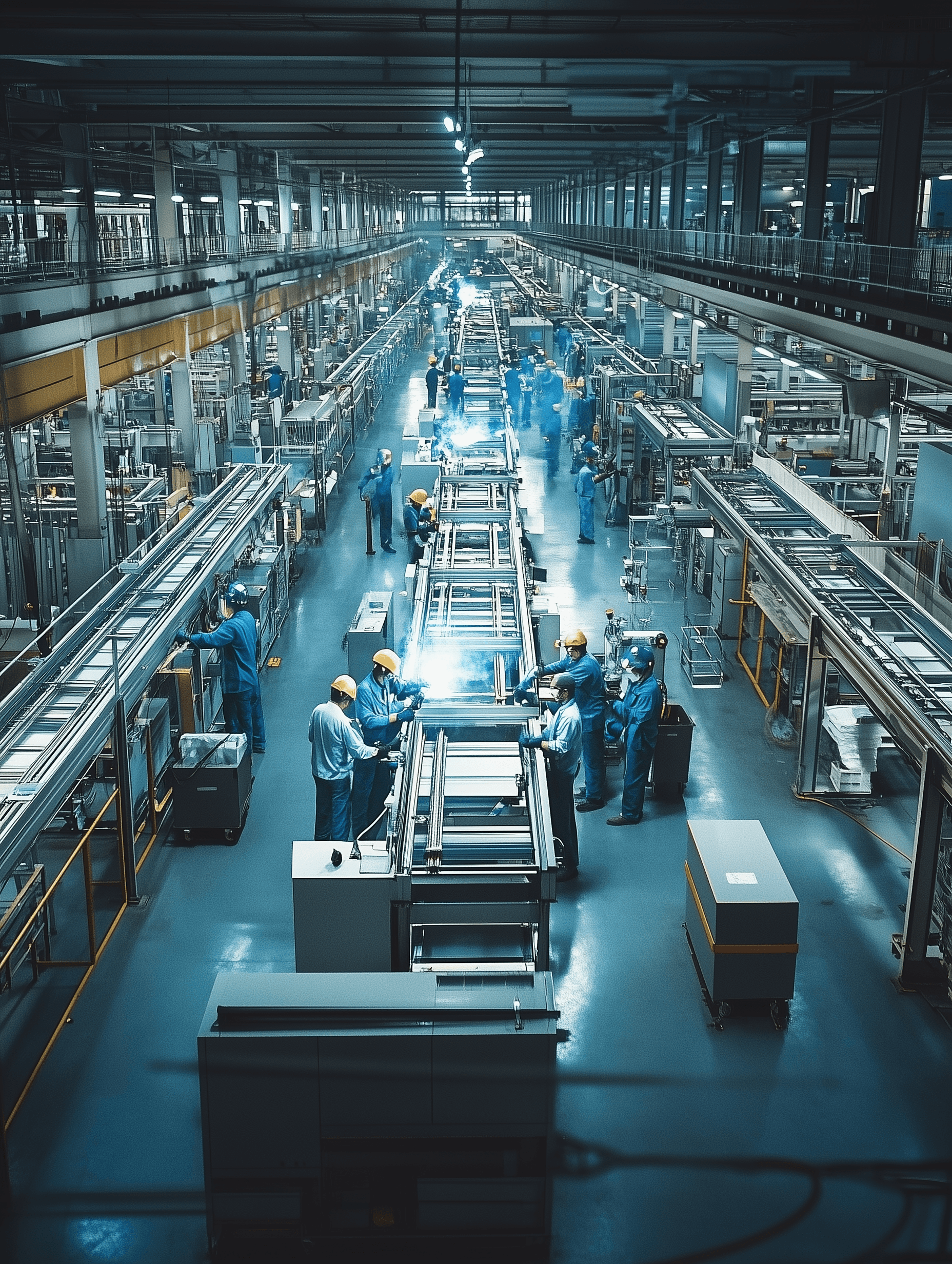

A comprehensive overview of our proven products and services, trusted across diverse industries including automotive, construction, and manufacturing.

Explore

Case Studies

A comprehensive overview of our proven products and services, trusted across diverse industries including automotive, construction, and manufacturing.

Get Started Today!

Get started with Eigen OneView | Cloud

Now available for a free trial - Book Today.

Trusted By Industry Leaders

Trusted By Leaders