Thermal sensors are known for their effectiveness in monitoring temperature changes in quality-related processes, such as welding in plastics and metals, adhesives dispersement and more. But how do thermal cameras perform in processes lacking a thermal profile? Can the advantages of thermal imaging be extended to processes where the inspected items are not inherently hot – or cold?

Challenges in Metal Surface Inspection

Manufacturers that produce polished metal need surface inspection solutions capable of detecting subtle imperfections in smooth and highly reflective metal surfaces. The defects – including scratches, patches and pits – often occur during the polishing process. While visible light (optical) camera sensors can identify some defects, they have limitations – especially when it comes to subtle defects. Light and shading make it challenging for optical cameras to generate images that clearly show the defect features. Without being able to see them, training an AI inspection model is difficult.

Common, difficult-to-detect defects in metal surfaces. SOURCE – Yang, Tianle & Li, Jinghui. (2023). Steel Surface Defect Detection Based on SSAM-YOLO. International Journal of Information Technologies and Systems Approach. 16. 1-13. 10.4018/IJITSA.328091.

Innovative Approach: Thermal Deflectometry for Metal Surface Inspections

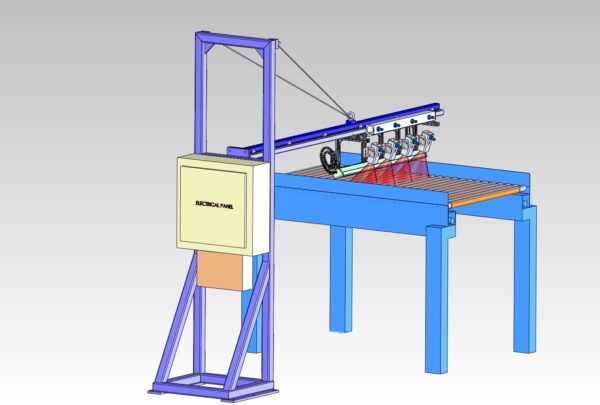

When deploying optical cameras, deflectometry is commonly used to find or highlight features by reflecting light off the surface. Thermal deflectometry works the same way except instead of light – you use a combination of heat and light. Since metal surfaces are heat resistant, heat can be radiated on the smooth metal surface and measure the reflection.

This illustration provides an example of an inline inspection solution that Eigen designed where heat is reflected off high-shine metal sheets to capture images with thermal cameras.

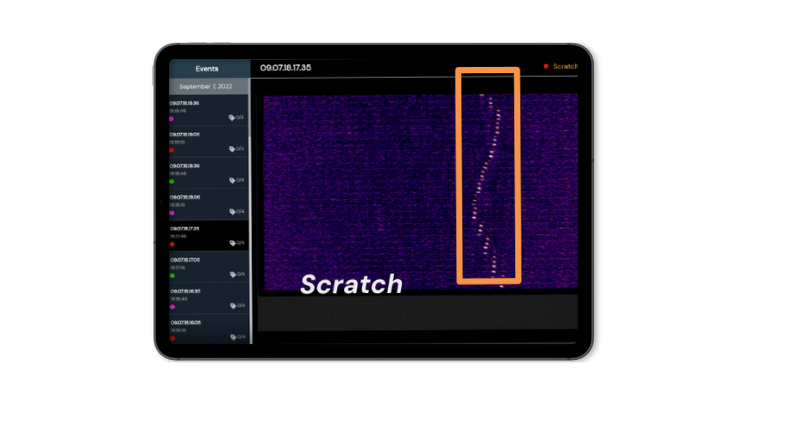

This technique eliminates challenges associated with reflective light. The heat projected onto the surface enhances the quality of the data captured. Utilizing the reflected heat and improved images makes it possible to train AI inspection models to detect the previously “invisible” surface issues.

Advantages of the Thermal Deflectometry Approach

The deflection approach offers numerous advantages, including:

1. Eliminating issues related to reflective light,

2. Projecting controllable and reliable heat onto the surface,

3. Capturing reflected heat efficiently with the thermal sensors,

4. Generating data to train AI inspection models to identify multiple surface defects.

This solution introduces more hardware components than typical machine vision inspection cells. However, the reliability of this approach has been proven. Environmental conditions inside the factory that can impact the inspection process are removed. The image sizes allow for efficient processing and background/noise removal is easier which helps speed up AI accuracy.

Build & Deploy Easy-to-Manage Thermal Deflectometry Inspection Solutions

The majority of manufacturers don’t have in-house machine vision and AI expertise. Production and Quality engineers want “low-touch”, easy-to-use solutions that generate the data they need to inspect every product they make.

When considering adding a vision solution, ensure it is “connected” – integrated with existing machines and production infrastructure. In doing so, data from machines, sensors and other critical sources can be consolidated to generate AI inspection models that deliver the most comprehensive inline inspections.

A scratch on a shiny metal surface that was undetectable by inspectors and optical cameras becomes clearers visible when using our thermal deflectometry solution.

When the solution design is configured with the same software used to manage it, scaling to other machines and lines becomes easier. Our OneView software includes tools for initial configuration and integration that can be saved as templates – making subsequent deployments faster. When the solution configuration is repeated, the data collected is the same meaning that one inspection model can be used across machines.

And when considering an inline inspection solution, make sure it’s future-proof. We work with many customers who have deployed rules-based inspection solutions that are limited to detecting 1-2 defects and difficult to manage. AI-powered inspections can learn and evolve – meaning the solution is adaptable and can detect multiple defect types.

Need Inline Inspections on Cool Surfaces? We Can Help!

With a team of certified thermographers and software built to leverage the power of thermal imaging, Eigen is well-equipped to address quality issues effectively. We have helped various customers design and deploy solutions featuring thermal cameras. Read more about them here.

We have partnerships with leading camera manufacturers like Teledyne Flir and Optris which further enhance our ability to provide top-tier solutions.

Contact our team here to discuss adding thermal-powered inline inspections to machines today!