When it comes to inline machine vision solutions for inspecting painted automotive parts, most systems have focused on car bodies. But what about all those other parts like bumpers, cover panels and fenders?

“Machine vision solutions for plastic painted parts either didn’t meet customers’ needs, were difficult to deploy or were just too expensive,” explains James Finch, Director of Customer Success at Eigen. “That’s why the bulk of the parts manufacturers are continuing to rely on subjective, labour-intensive manual inspection.”

SEE IT – AN INLINE VIEW OF EVERY PART

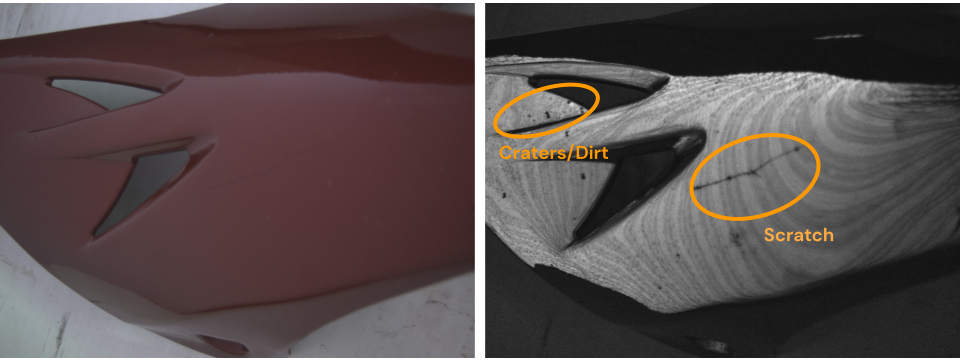

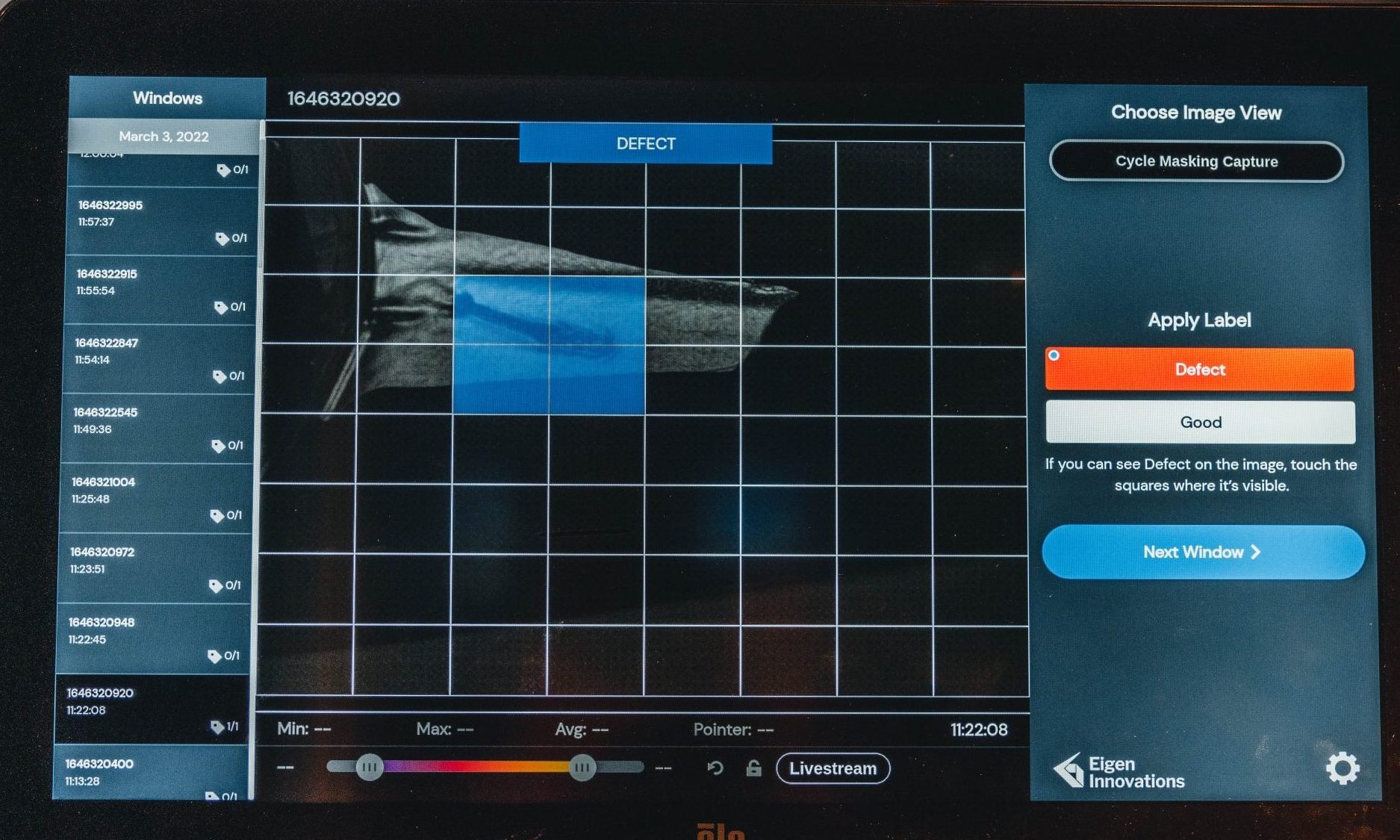

To address this gap, Eigen developed an innovative image capture technique that allows for the capture of the entire surface of a wide variety of parts as they move along the paint line. This unique approach combined with Eigen’s novel image enhancement and standardization tools finally makes part-over-part monitoring and quality inspection a reality.

“From dirt to scratches and orange peel to craters, our software can accurately detect many common defects that previously required diverse inspection methods and left the door open to defect escape,” said Finch. “Seeing these common defects sooner is a major improvement over end-of-line inspection.”

Using Eigen’s software on the factory floor, team members receive alerts when issues are detected, can review inspection images and take the appropriate action with flagged parts.

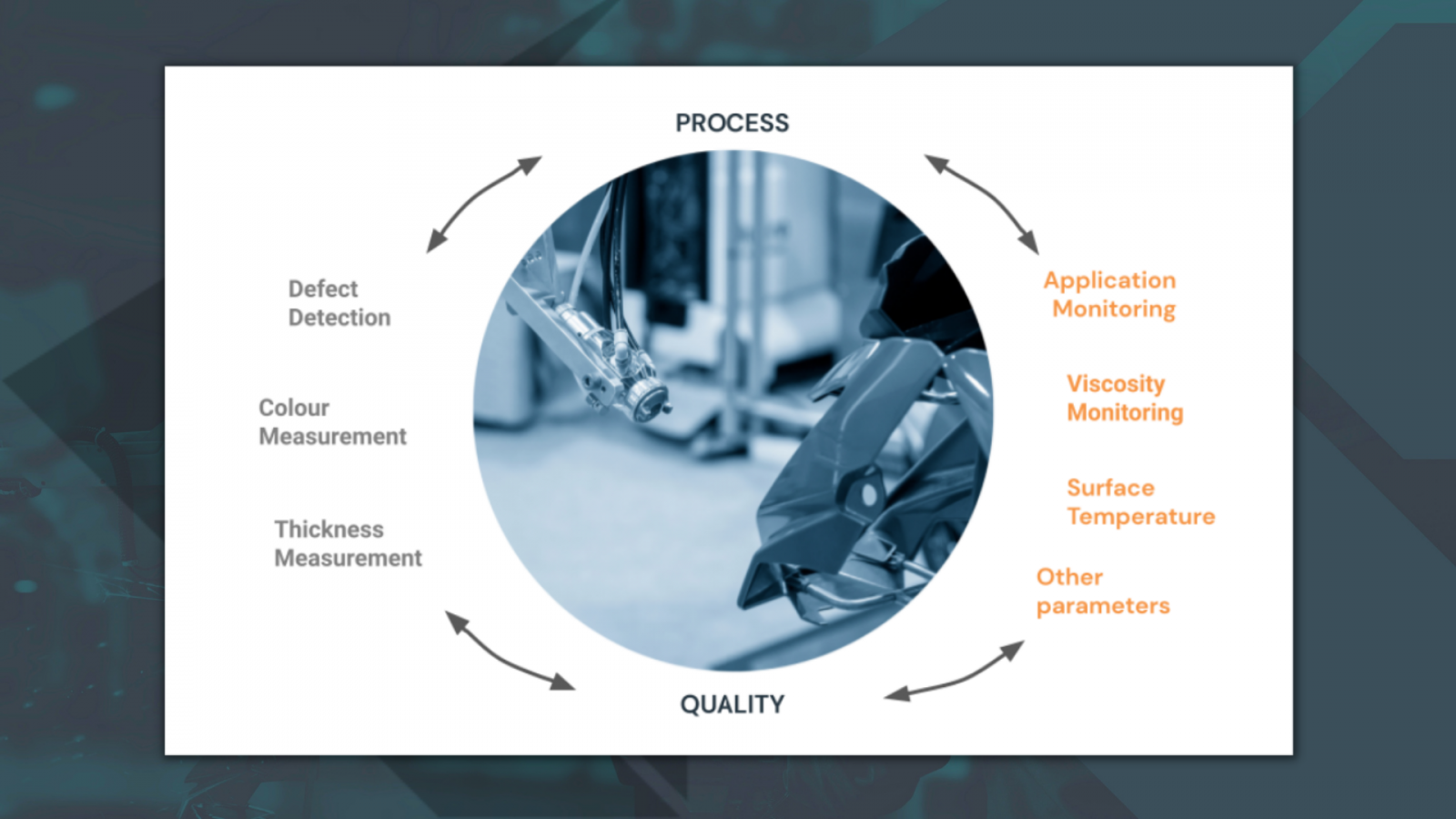

SOLVE IT – QUALITY & PROCESS ANALYTICS & INSIGHTS

By adding process data to the mix, Eigen’s machine vision software goes beyond basic inspection. Process data correlated to each inspection image generates a digital part record. By analyzing these records, teams can see how variation leads to defects and adjust process controls to prevent defects moving forward. The software automates analysis and delivers insights that assist in defect prevention and process improvement.

“Process drift or variation is one of the main reasons for quality issues,” explains Finch. “This is especially true in paint processes where the goal is to duplicate the exact paint application, viscosity and other processes time after time. Our software helps achieve greater process consistency which translates into fewer defects – a game-changer for most manufacturers.”

SCALE IT – ENHANCED MONITORING & CONTROL ACROSS YOUR LINES

The benefits of deploying Eigen’s machine vision platform go beyond one line or machine.

The first deployment paves the way for rapid scaling to additional lines or factories. As they are brought online in the platform, analytics and insights expand from one machine to multiple, driving greater quality consistency and continuous improvement across operations.

Click here to download an overview of our paint quality and process monitoring solution.

If you’re interested in connecting with a member of our team, click here.