Blow-outs. Bent or missing bars. Broken welds. A lot can go wrong during your grate welds. When you’re striving to make every grate a great grate, discovering these issues during offline inspections simply doesn’t cut it.

Ensuring weld quality on your grates is essential for durability and integrity.

Fortunately, you no longer need to rely on traditional offline, time-consuming, subjective testing methods. Our inline weld inspection solution combines thermal imaging and AI to offer a powerful, real-time alternative inspection method that increases accuracy, speed, and consistency.

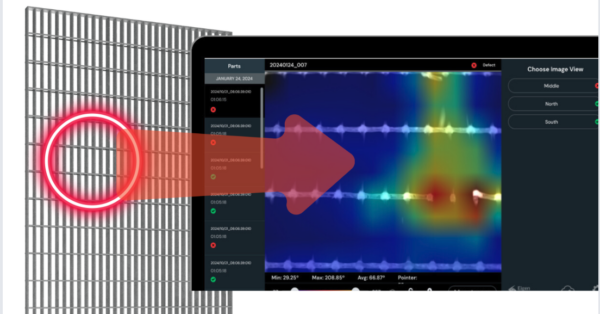

Eigen’s inline solution combines thermal imaging and AI to deliver real-time grate weld inspections.

Grate manufacturers using Eigen’s integrated weld inspection solution have established a new standard for inline inspections and traceability and are realizing the following benefits and competitive advantages…

1. Improved Detection Accuracy

Thermal imaging captures temperature profiles of welds needed to detect potential defects not visible to the naked eye. These defects, such as cracks, weak spots, and inconsistencies, generate subtle temperature changes that thermal cameras can detect. When combined with AI, thermal imaging allows teams to train inspection models that interpret these temperature profiles to distinguish between acceptable variations and true defects.

2. Faster and More Comprehensive Inspections

Manually inspecting metal grate welds is labour-intensive and requires inspectors to closely examine each weld, a process that is often prone to fatigue-induced errors. Thermal imaging, however, enables the capture of comprehensive heat signatures within seconds. By integrating AI algorithms, the data from thermal images can be analyzed instantly, with AI models trained to recognize defects with high accuracy. This automation allows for rapid, consistent inspections, boosting overall productivity and minimizing downtime.

An AI model inspects grate welds in real-time and flags various defects. When the same data is captured across machines and lines, one model can be used for inspections – bringing greater consistency across your grate production.

3. Consistency and Objectivity

Human inspectors’ quality interpretations can vary based on experience, training, and environmental factors. Thermal imaging paired with AI minimizes this subjectivity. An AI model applies the same parameters and rules to every inspection, providing a uniform standard for every quality assessment. This ensures that all metal grate welds are held to the same rigorous standards, regardless of inspector variability.

4. Early Fault Detection for Predictive Maintenance

Thermal imaging and AI inspections can help identify thermal anomalies in welds that indicate early-stage process issues before they escalate into severe problems. By analyzing standardized inspection records, teams can identify subtle process variations, determine potential risks and take proactive maintenance measures. This proactive maintenance capability helps prevent defects, reduces the risk of costly downtime, and ultimately extends the lifecycle of metal grates.

5. Data-Driven Insights for Quality Control

Teams use digital inspection records to track, analyze, and report on weld quality over time. These insights provide valuable feedback on manufacturing processes allowing companies to identify trends, pinpoint recurring issues, and improve weld quality in future production runs. The data generated by AI and thermal inspections support continuous improvement initiatives and reinforce quality control protocols.

Eigen’s “Inte-Grated” Weld Inspection Solution

When we say “inte-grated”, we mean it. We configure our solution to ensure it delivers your desired inspection results. We facilitate the procurement and installation of equipment (thermal cameras, industrial PC, HMI, cables, etc.) to ensure you capture all the data (images and process) you need to automate your inspections.

Once the solution is fully connected, we help you generate and deploy your first AI inspection model. Our OneView software displays inspection results on an interactive screen in the factory. Teams can access Oneview online to access inspection records across deployments, analyze and provide feedback on inspection records, monitor inspection model performance and customize their monitoring and reports.

Now With Enhanced Model Explainability

When adopting AI-enabled solutions, your team must have confidence in the inspection model. That confidence requires context and visibility. Along with providing a Thermal View of the inspection result, we’ve added a Heatmap View to our weld inspection solution. This view pinpoints and highlights the area on the grate where the model has detected a defect. Using the HMI installed at the welder, Operators can quickly review the heatmap image to confirm the inspection result.

Seeing is believing. Our new Heat Map View helps Operators see and understand the defects flagged by our inpsection model.

The Future of Grate Weld Inspection

Deploying thermal imaging and AI-enabled inspections for metal grate welds is a game-changer from a quality assurance perspective. Enhanced detection accuracy, reduced inspection time and early fault detection combine to provide a compelling case for our solution.

As manufacturers strive for optimal quality, inline, AI-driven thermal inspections represent a vital tool for spotting defects that can compromise structural integrity. For companies invested in safety and innovation, embracing inline inspections is a logical step toward ensuring product quality, minimizing downtime, and reducing scrap

Want more information?

Click here to read a case study about one manufacturer’s experience deploying our inspection solution.

Click here to download our Metal Grate Weld Inspection Solution Brief.

Or complete the form below and we’ll contact you to discuss your specific grate weld inspection needs.