Improved streak detection is delivering annual savings of approximately $1M.

$1M of Annual Savings

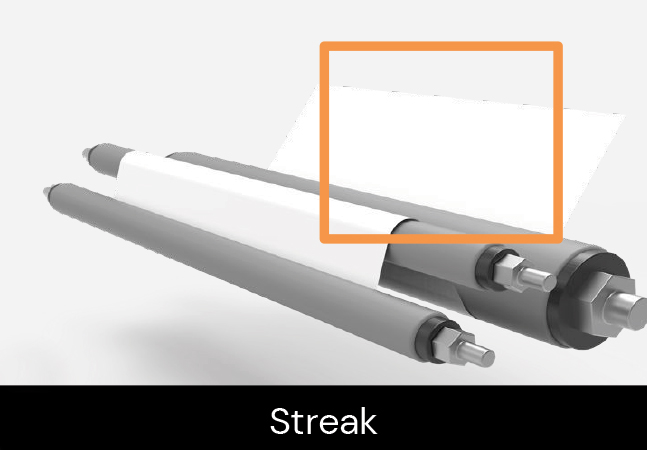

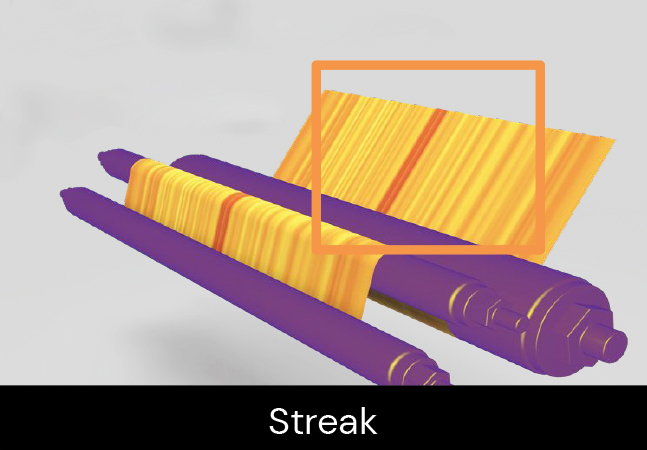

One of the world’s leading specialty paper manufacturers was experiencing unnecessary downtime and equipment costs due to coating build-up that caused cold streaks in their specialty, high-gloss paper product.

Before Eigen

- Basic vision systems (e.g. optical cameras) were unable to detect subtle changes in sheet characteristics and moisture content.

- Coating build-up events occurred in under 10 seconds making it impossible for operators to react.

- 3 machines in one factory experienced over 30 events, resulting in calendar damage and unnecessary downtime.

With Eigen

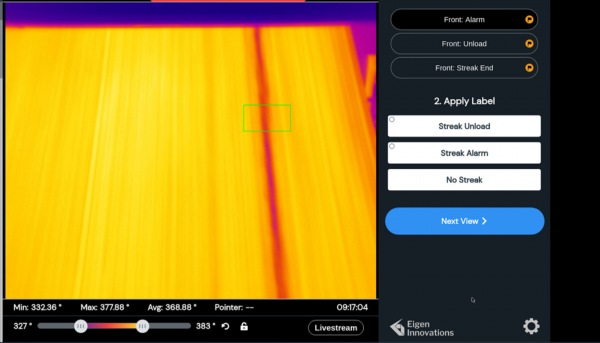

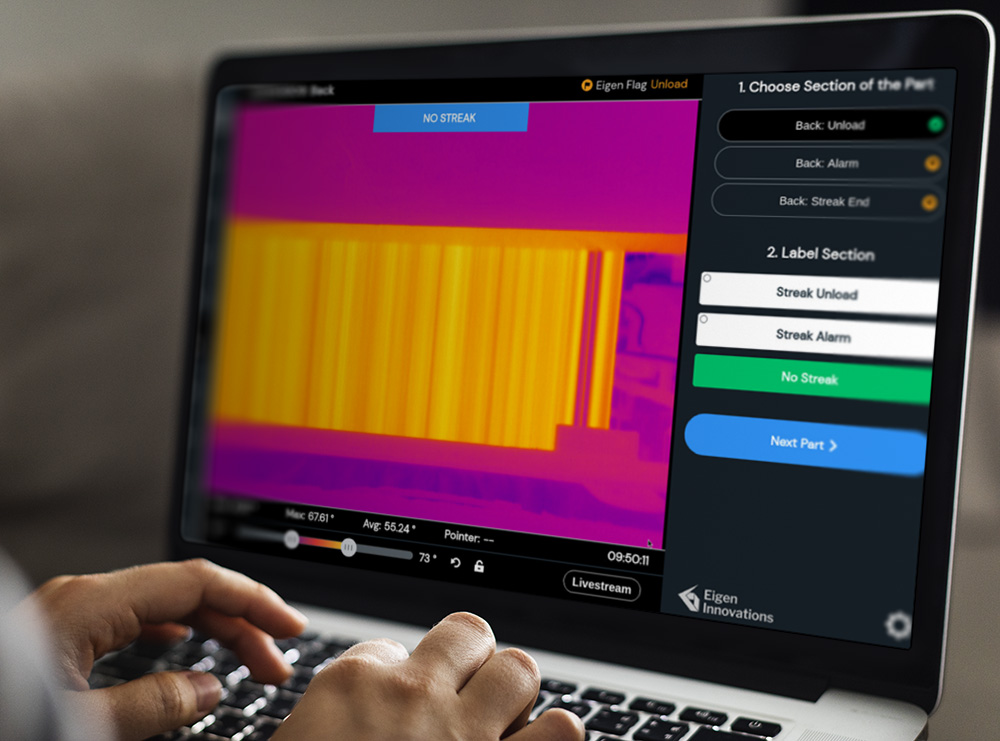

- Rapid deployment in factory – FLIR thermal cameras installed along the web & Eigen Edge device collecting image data.

- Eigen designed a real-time streak detection algorithm based on image data and client input.

- Eigen Edge system connected directly to each machine’s respective PLCs to enable self-activated pressure reductions on the calendars – automatically protecting them from coating build-up and opening calendars upon streak detection.