Industry: Construction Materials | Headquarters: Canada | Employees: 3,000

A drywall and plasterboard manufacturer wanted to reduce reliance on sample destructive testing and assess quality as drywall sheets left the heating chamber.

Industry: Construction Materials | Headquarters: Canada | Employees: 3,000

A drywall and plasterboard manufacturer wanted to reduce reliance on sample destructive testing and assess quality as drywall sheets left the heating chamber.

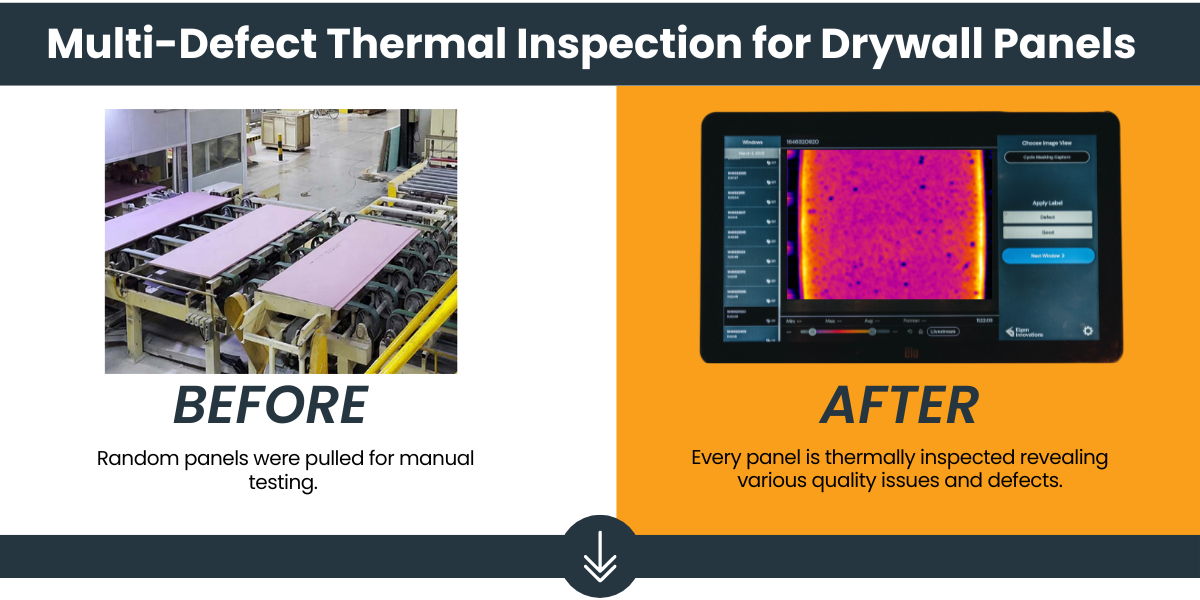

During the drying process, invisible defects can occur between the outer paper layers of drywall and wallboard. Thermal imaging and AI-inspection models trained to detect various defects help the manufacturer ensure that sheets with voids and other defects do not leave the factory.

Eigen’s thermal inspection solution features thermal cameras that inspect the drywall panels as they leave the heating chamber. AI inspection models alert Operators when surface, moisture or thickness anomalies are detected.

Using its OneView software, the team now uses consolidated image and process data in the digital inspection records to analyze data to quickly determine what caused the issues and adjust processes to prevent them from reoccurring.

Post-Heating, Standardized Inspection

Real-Time Operator Alerts

100% Traceability