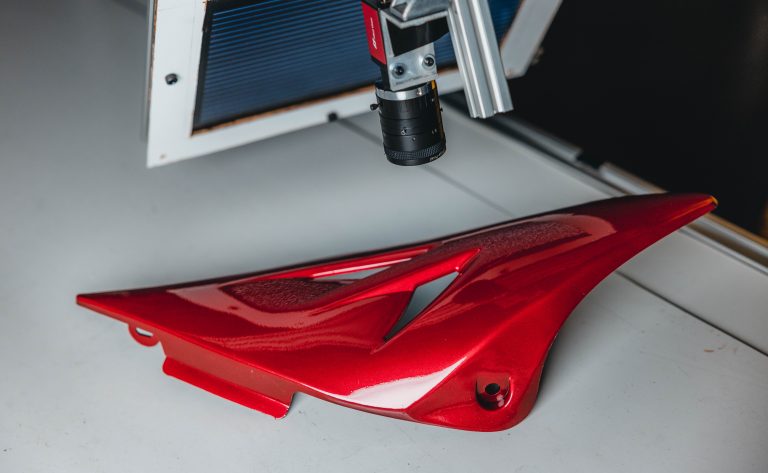

When it comes to high-gloss painted parts like the one pictured here, automotive parts manufacturers rely heavily on human inspectors to detect issues in paint quality on plastic parts. While these inspectors have an impressive ability to detect defects, they are increasingly in short supply. If hiring and maintaining trained inspectors is a challenge in your factory OR if your team needs additional tools and technologies to support their inspection and monitoring efforts, Eigen can help.

Reduce Reliance on Sample Testing

Before – Manual + Sample Lab Testing

- Two or more inspectors review parts as they come down the line.

- Sample parts are pulled to conduct more extensive quality testing – typically in a lab environment.

- Various tools and testing techniques are required for comprehensive inspection and analysis.

- Lagging quality metrics make real-time troubleshooting impossible.

- Lack of correlated quality and process data requires manually pulling data from various sources to carry out root cause analysis.

After – Part-over-Part Quality + Process Monitoring

- Optical cameras installed on the line capture images of the entire surface of every part.

- Edge processors ingest image AND process data to create a “digital twin” of each part – a traceable record that unlocks ongoing quality and process monitoring.

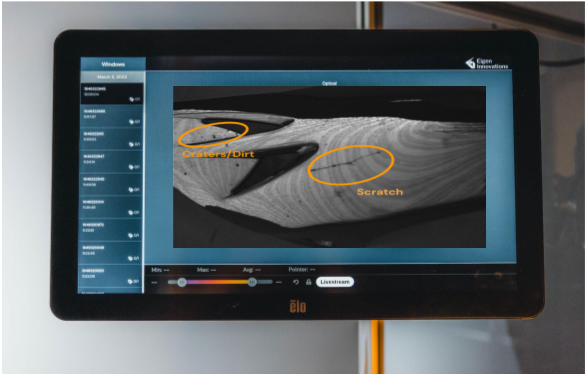

- Machine learning models monitor for defects such as craters, scratches, dirt, orange peel, etc. as well as process anomalies and alert inspectors via an HMI installed on the line.

- Eigen’s machine vision software analyzes digital records to identify trends and generate insights that streamline troubleshooting and root cause investigations and enables defect prevention and process improvement.

- Additional sensor or process data fed into Eigen’s machine vision software platform expands analytics and insights capabilities.