A Tier 1 automotive parts manufacturer was having difficulty “seeing” critical surface defects during the molding process resulting in rejected parts from their customers.

Helping Manufacturers See The Unseen

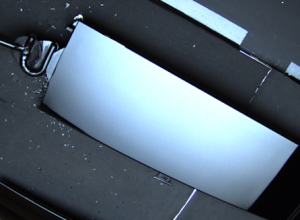

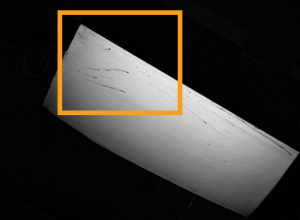

Before – Operator Visual Inspection

- Operators inspecting parts after the molding process could not see quality issues such as short shots, splay and read-through defects.

- Additional time was required to move the parts to another area with better lighting to attempt to confirm the defects.

- These inspections were highly subjective, varying from one operator to another.

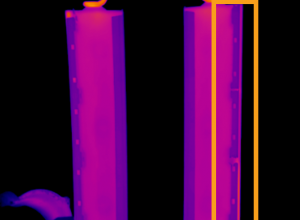

After – Eigen Visual Inspection

- FLIR thermal and optical cameras were installed at the molding station.

- A lighting display was installed to overcome the visibility issues making the surface defects “pop” in the captured images.

- Eigen edge devices collected image and process data.

- Using the high-resolution image and process data, Eigen’s machine-learning specialists designed and deployed models to provide superior inspection – detecting all three defects in real-time.

Why Eigen?

There are many providers of vision systems, but there is only one Eigen.

Built for Scale

Our platform is designed to help manufacturers deploy computer vision across cells, lines and factories.

Easy Interface

Our platform is designed to be self-service for quality engineers, process engineers and other industrial personas.

Many Capabilities

Regardless of where you are in your computer vision journey, we have designed a platform that can help you, from the earliest stages to the most mature implementations.

By Industry, For Industry

Eigen was founded, and the tools were built, by people who come from industry. With decades of experience in automotive, process, CPG and other industries, we understand your challenges.