Design, deploy and manage standardized inline inspection solutions.

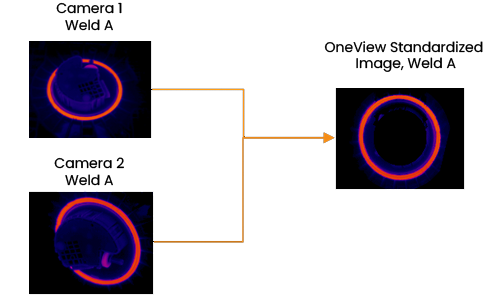

Standardized, Digital Records of Every Part

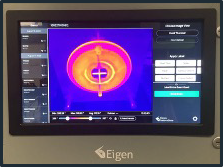

Automated Digital Inspections at Your Machine

Unlock Closed-Loop Automation & Enrich Quality Data

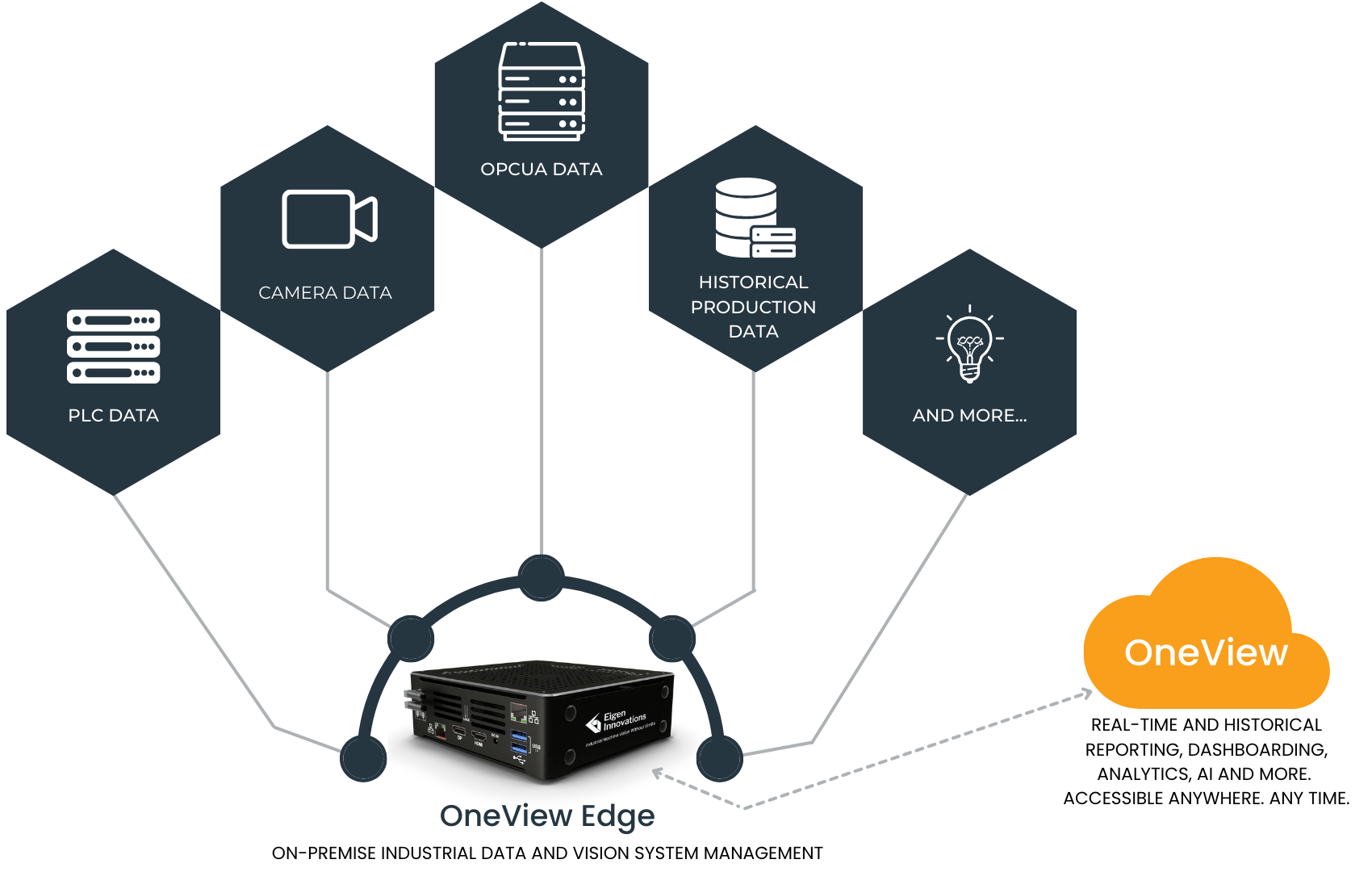

Easily Connect to In-Factory & Cloud Data Sources