Space is limited. Don’t miss Out.

Register Today!

Inspecting plastic automotive parts is difficult. Those defects that lurk beneath the surface are invisible to the naked eye and you only catch them during destructive or post-production inspections.

What if you could see those defects in welds and injection molded parts as they occur?

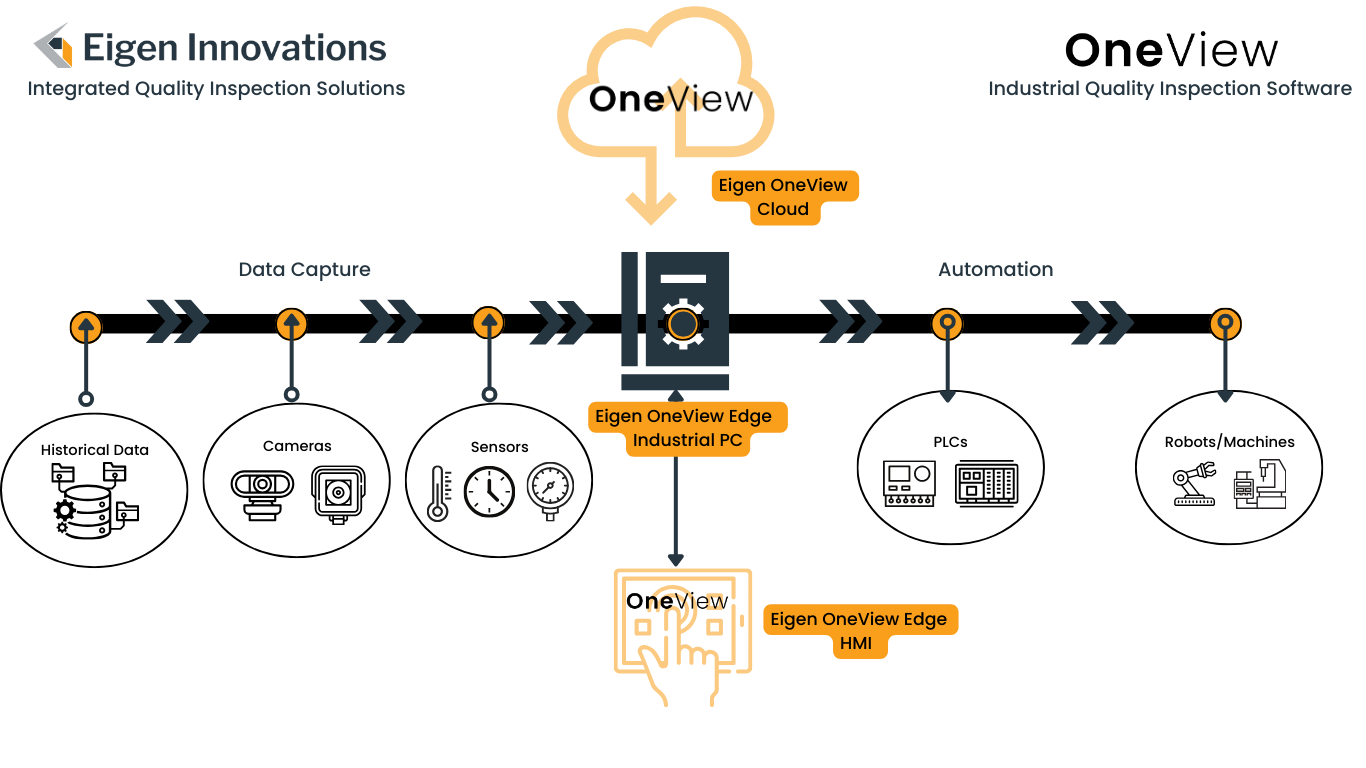

Eigen Innovations’ inline thermal inspection solutions for manufacturing combine the power of thermal imaging and AI-enabled inspections to detect defects as they happen. Our automated thermal inspections allow you to ensure every part is inspected the same way. Based on your inspection needs, we’ll source the hardware (camera(s), industrial PC(s), HMI, cabling, etc.), manage your initial installation, provide training on how to use our software to train inspection models and manage your solution(s) and assist you with setting up closed-loop automation.

If you want to catch hidden defects inline, reduce destructive testing and mitigate warranty claims and recalls, this webinar is for you!

If you need to inspect every part, expand part traceability or overcome resource gaps on your team, we’ll cover all this and more…

- How Real-Time Thermal Inspections Work: What is thermal imaging and how our unique imaging processing and AI inspection tools can deliver inspections in real-time.

- Solution Integration and Software Demo: See how we help you integrate thermal cameras and hardware on your line and a demo of our OneView Inspection Software.

- Key Benefits for Manufacturers: See how adopting integrated thermal inspection solutions can reduce scrap rates, improve product quality and significantly save on costs.

- Real-World Applications: Hear how automotive parts factories have adopted our inspection solutions to inspect every part and generate inspection records and data they can use to prevent defects.

- Q&A with the Experts: Ask members of our team questions about your inspection needs

Who Should Attend?

Quality control managers, process engineers, production managers, and anyone involved in ensuring product quality and operational efficiency – especially with plastic welding, injection molding and extrusion applications.

Webinar Details

- Who: James Finch, Eigen COO & Josh Pickard, Sr. Director Product & Innovations

- Date: Thursday, October 3, 2024

- Time: 9 a.m. EDT

Thermal cameras are just one data streams we integrate into our integrated inspection solutions. Attend the webinar to learn more about all the data we capture and consolidate and how our solutions provide seamless closed-loop automation.