Plastics

Real-time thermal inspection that captures the full temperature profile of extruded sheet and film, enabling early detection of defects and more stable thermoforming performance.

The Challenge

Thermoforming quality is determined long before a part reaches the mold. Both plastic sheet and film depend on tightly controlled heating and cooling cycles, where even small temperature inconsistencies can lead to voids, warp, uneven thickness, incomplete melt, and die lines.

Traditional thermocouples only measure a single point on the sheet, leaving operators blind to the larger thermal profile across the width and length of the product. As line speeds increase and material recipes vary, maintaining uniform temperature becomes even harder. Without a complete thermal view, process drift often goes unnoticed until it becomes scrap, rework, or inconsistent forming performance.

Our Solution

Eigen’s AI-powered thermoforming monitoring system provides a full-width, full-length thermal profile of the sheet as it exits the die. The system captures thousands of temperature points in real time, allowing operators to see the exact temperature distribution that drives material behavior downstream.

Instead of relying on isolated point sensors, the system uses high-speed thermal imaging to identify cold spots, hot streaks, incomplete melt, or trapped air such as voids that are hidden beneath the surface. Machine learning models trained in OneView combine these thermal images with key process parameters such as melt temperature, melt pressure, cycle time, and line speed. This creates a unified digital record for every part.

The system continuously analyzes this dataset to detect defects and anomalies instantly. When issues appear, operators receive immediate notifications and can take corrective action before non-conforming material accumulates. Quality and process teams use the history of analyzed images and parameters for troubleshooting, trend analysis, and long-term defect prevention.

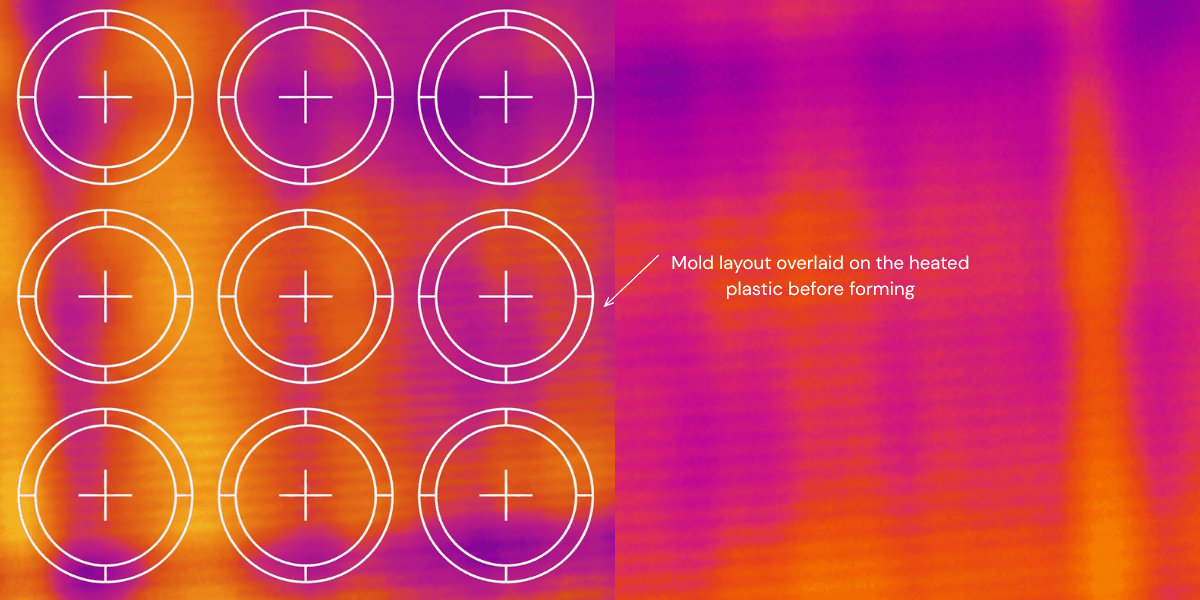

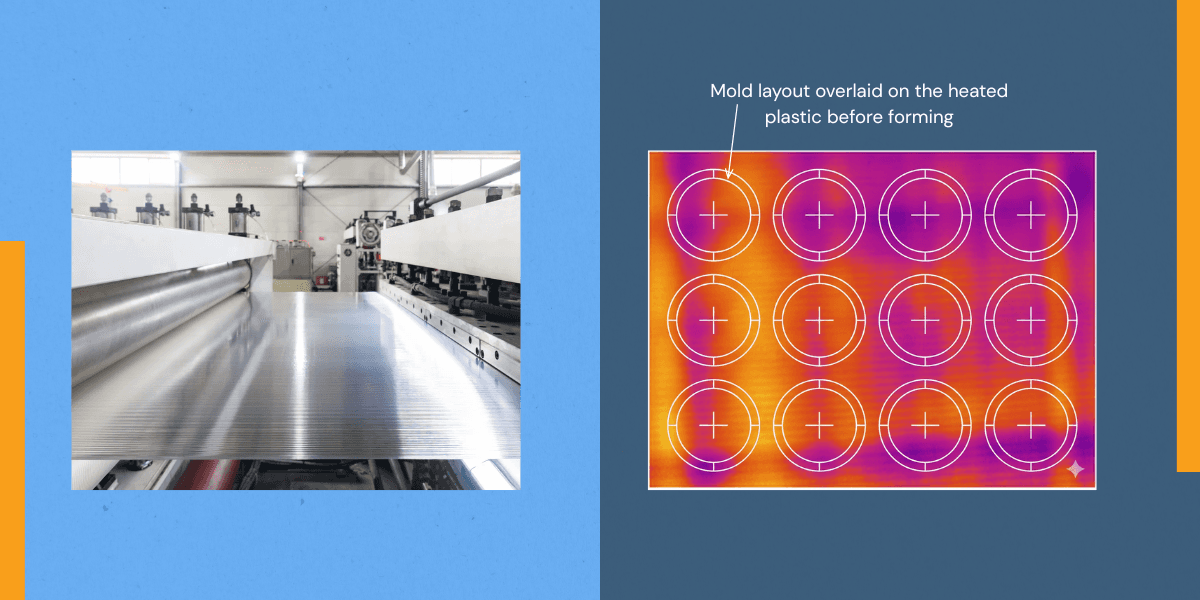

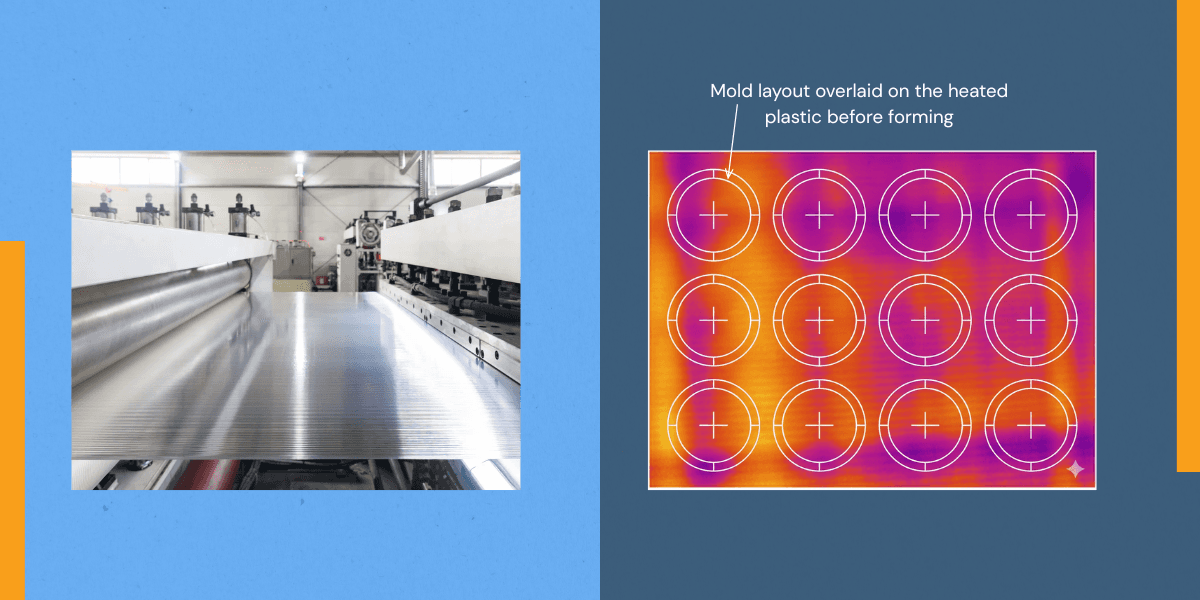

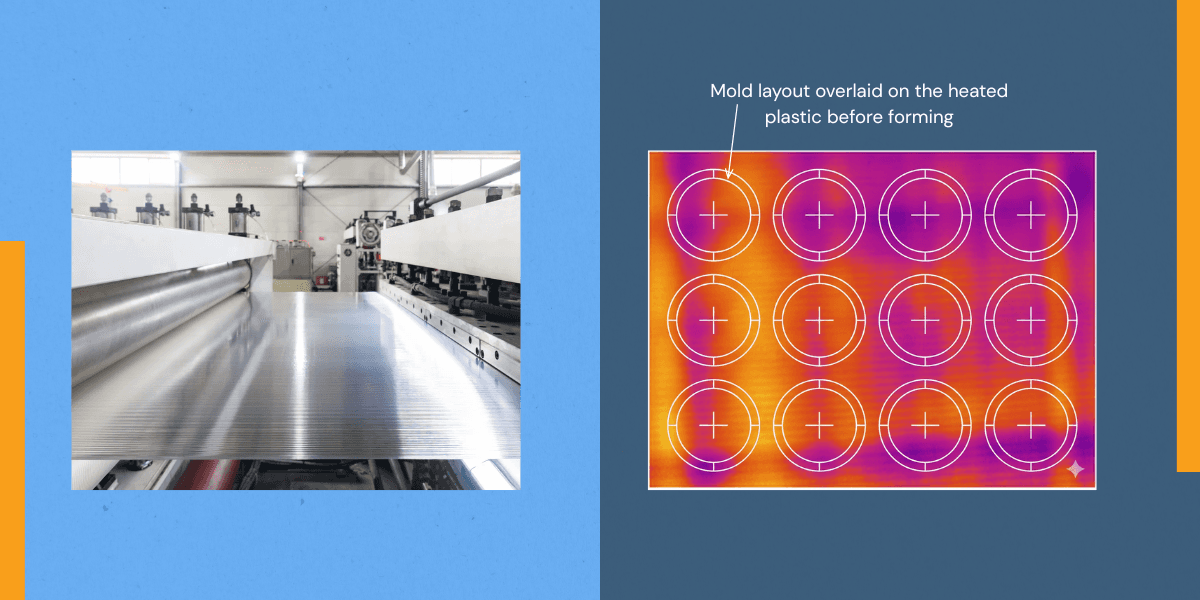

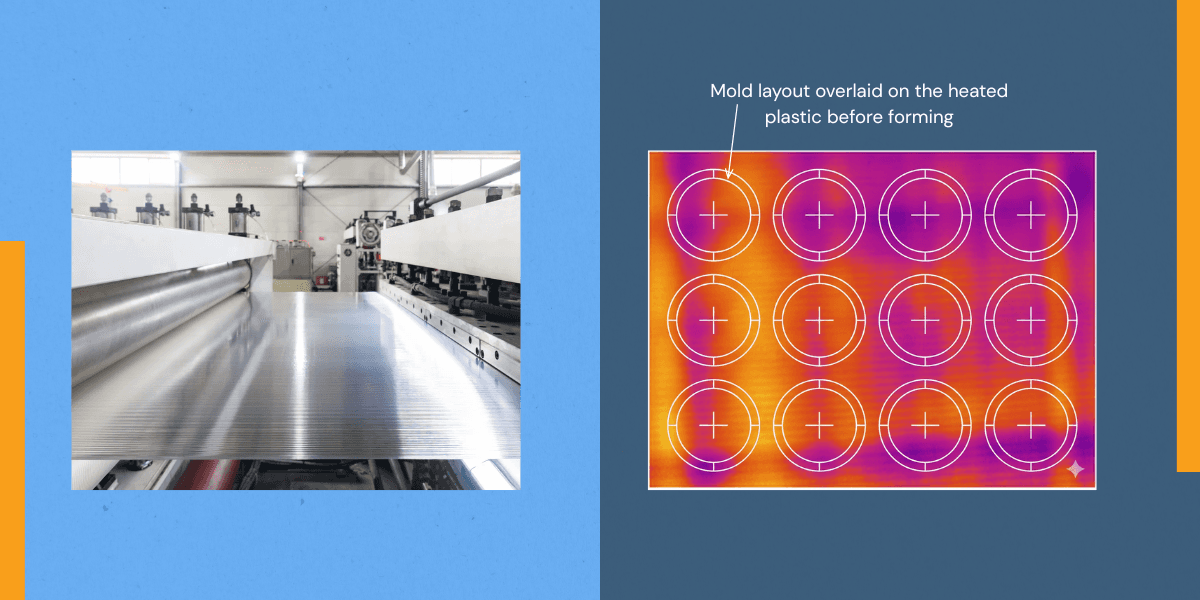

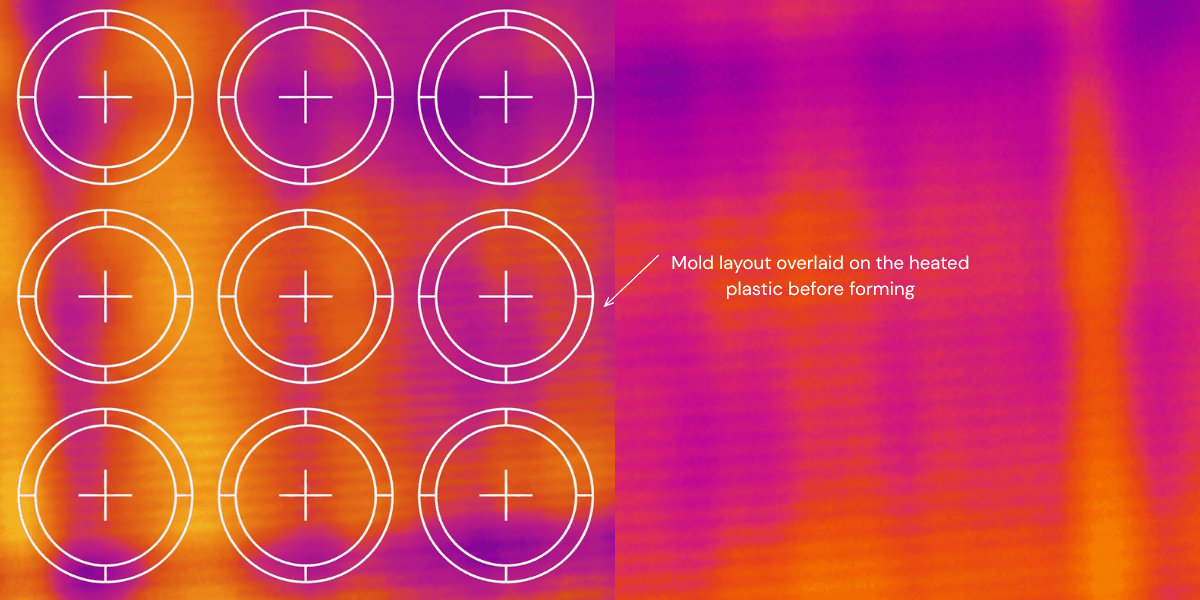

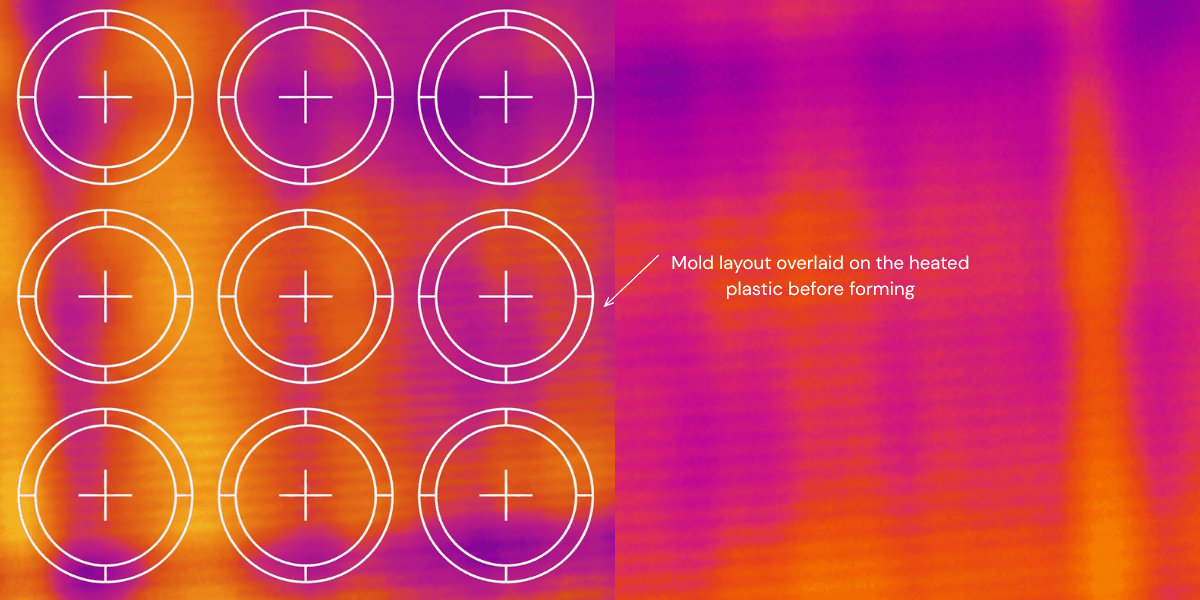

Operator view vs Eigen view

A side-by-side comparison that shows how thermal vision reveals internal temperature variation and displays the mold layout overlaid on the heated sheet before forming.

Benefits

Complete Thermal Coverage: Full-width thermal imaging detects voids, warp, thickness variation, incomplete melt, and die-line formation in real time.

Fewer Hidden Defects: Identifies trapped air and cold spots that are not visible to operators, preventing downstream forming issues.

Stable and Predictable Forming: Real-time feedback supports better control of heaters, die settings, and cooling rates.

Integrated Data Record: Thermal images and process parameters are automatically linked to each part, creating a traceable digital record.

Proactive Quality: AI-driven analytics uncover recurring issues, correlate them to machine conditions or material changes, and reduce rework.

Scalable and Flexible: Works across diverse sheet materials, thicknesses, and line speeds without manual recalibration.

Reduced Waste: Early detection helps maintain uniformity, prevents forming defects, and supports faster and more consistent production.

The Challenge

Thermoforming quality is determined long before a part reaches the mold. Both plastic sheet and film depend on tightly controlled heating and cooling cycles, where even small temperature inconsistencies can lead to voids, warp, uneven thickness, incomplete melt, and die lines.

Traditional thermocouples only measure a single point on the sheet, leaving operators blind to the larger thermal profile across the width and length of the product. As line speeds increase and material recipes vary, maintaining uniform temperature becomes even harder. Without a complete thermal view, process drift often goes unnoticed until it becomes scrap, rework, or inconsistent forming performance.

Our Solution

Eigen’s AI-powered thermoforming monitoring system provides a full-width, full-length thermal profile of the sheet as it exits the die. The system captures thousands of temperature points in real time, allowing operators to see the exact temperature distribution that drives material behavior downstream.

Instead of relying on isolated point sensors, the system uses high-speed thermal imaging to identify cold spots, hot streaks, incomplete melt, or trapped air such as voids that are hidden beneath the surface. Machine learning models trained in OneView combine these thermal images with key process parameters such as melt temperature, melt pressure, cycle time, and line speed. This creates a unified digital record for every part.

The system continuously analyzes this dataset to detect defects and anomalies instantly. When issues appear, operators receive immediate notifications and can take corrective action before non-conforming material accumulates. Quality and process teams use the history of analyzed images and parameters for troubleshooting, trend analysis, and long-term defect prevention.

Operator view vs Eigen view

A side-by-side comparison that shows how thermal vision reveals internal temperature variation and displays the mold layout overlaid on the heated sheet before forming.

Benefits

Complete Thermal Coverage: Full-width thermal imaging detects voids, warp, thickness variation, incomplete melt, and die-line formation in real time.

Fewer Hidden Defects: Identifies trapped air and cold spots that are not visible to operators, preventing downstream forming issues.

Stable and Predictable Forming: Real-time feedback supports better control of heaters, die settings, and cooling rates.

Integrated Data Record: Thermal images and process parameters are automatically linked to each part, creating a traceable digital record.

Proactive Quality: AI-driven analytics uncover recurring issues, correlate them to machine conditions or material changes, and reduce rework.

Scalable and Flexible: Works across diverse sheet materials, thicknesses, and line speeds without manual recalibration.

Reduced Waste: Early detection helps maintain uniformity, prevents forming defects, and supports faster and more consistent production.

The Challenge

Thermoforming quality is determined long before a part reaches the mold. Both plastic sheet and film depend on tightly controlled heating and cooling cycles, where even small temperature inconsistencies can lead to voids, warp, uneven thickness, incomplete melt, and die lines.

Traditional thermocouples only measure a single point on the sheet, leaving operators blind to the larger thermal profile across the width and length of the product. As line speeds increase and material recipes vary, maintaining uniform temperature becomes even harder. Without a complete thermal view, process drift often goes unnoticed until it becomes scrap, rework, or inconsistent forming performance.

Our Solution

Eigen’s AI-powered thermoforming monitoring system provides a full-width, full-length thermal profile of the sheet as it exits the die. The system captures thousands of temperature points in real time, allowing operators to see the exact temperature distribution that drives material behavior downstream.

Instead of relying on isolated point sensors, the system uses high-speed thermal imaging to identify cold spots, hot streaks, incomplete melt, or trapped air such as voids that are hidden beneath the surface. Machine learning models trained in OneView combine these thermal images with key process parameters such as melt temperature, melt pressure, cycle time, and line speed. This creates a unified digital record for every part.

The system continuously analyzes this dataset to detect defects and anomalies instantly. When issues appear, operators receive immediate notifications and can take corrective action before non-conforming material accumulates. Quality and process teams use the history of analyzed images and parameters for troubleshooting, trend analysis, and long-term defect prevention.

Operator view vs Eigen view

A side-by-side comparison that shows how thermal vision reveals internal temperature variation and displays the mold layout overlaid on the heated sheet before forming.

Benefits

Complete Thermal Coverage: Full-width thermal imaging detects voids, warp, thickness variation, incomplete melt, and die-line formation in real time.

Fewer Hidden Defects: Identifies trapped air and cold spots that are not visible to operators, preventing downstream forming issues.

Stable and Predictable Forming: Real-time feedback supports better control of heaters, die settings, and cooling rates.

Integrated Data Record: Thermal images and process parameters are automatically linked to each part, creating a traceable digital record.

Proactive Quality: AI-driven analytics uncover recurring issues, correlate them to machine conditions or material changes, and reduce rework.

Scalable and Flexible: Works across diverse sheet materials, thicknesses, and line speeds without manual recalibration.

Reduced Waste: Early detection helps maintain uniformity, prevents forming defects, and supports faster and more consistent production.

The Challenge

Thermoforming quality is determined long before a part reaches the mold. Both plastic sheet and film depend on tightly controlled heating and cooling cycles, where even small temperature inconsistencies can lead to voids, warp, uneven thickness, incomplete melt, and die lines.

Traditional thermocouples only measure a single point on the sheet, leaving operators blind to the larger thermal profile across the width and length of the product. As line speeds increase and material recipes vary, maintaining uniform temperature becomes even harder. Without a complete thermal view, process drift often goes unnoticed until it becomes scrap, rework, or inconsistent forming performance.

Our Solution

Eigen’s AI-powered thermoforming monitoring system provides a full-width, full-length thermal profile of the sheet as it exits the die. The system captures thousands of temperature points in real time, allowing operators to see the exact temperature distribution that drives material behavior downstream.

Instead of relying on isolated point sensors, the system uses high-speed thermal imaging to identify cold spots, hot streaks, incomplete melt, or trapped air such as voids that are hidden beneath the surface. Machine learning models trained in OneView combine these thermal images with key process parameters such as melt temperature, melt pressure, cycle time, and line speed. This creates a unified digital record for every part.

The system continuously analyzes this dataset to detect defects and anomalies instantly. When issues appear, operators receive immediate notifications and can take corrective action before non-conforming material accumulates. Quality and process teams use the history of analyzed images and parameters for troubleshooting, trend analysis, and long-term defect prevention.

Operator view vs Eigen view

A side-by-side comparison that shows how thermal vision reveals internal temperature variation and displays the mold layout overlaid on the heated sheet before forming.

Benefits

Complete Thermal Coverage: Full-width thermal imaging detects voids, warp, thickness variation, incomplete melt, and die-line formation in real time.

Fewer Hidden Defects: Identifies trapped air and cold spots that are not visible to operators, preventing downstream forming issues.

Stable and Predictable Forming: Real-time feedback supports better control of heaters, die settings, and cooling rates.

Integrated Data Record: Thermal images and process parameters are automatically linked to each part, creating a traceable digital record.

Proactive Quality: AI-driven analytics uncover recurring issues, correlate them to machine conditions or material changes, and reduce rework.

Scalable and Flexible: Works across diverse sheet materials, thicknesses, and line speeds without manual recalibration.

Reduced Waste: Early detection helps maintain uniformity, prevents forming defects, and supports faster and more consistent production.

Read more

Thermoforming

Plastics

Real-time thermal inspection that captures the full temperature profile of extruded sheet and film, enabling early detection of defects and more stable thermoforming performance.

Download

Sheet

Solution

Thermoforming