Plastics

Injection Molding Inspection

Real-time AI thermal and optical inspection that helps manufacturers detect surface defects early, understand their root causes, and protect Class A quality across every molded part.

The Challenge

In automotive and appliance manufacturing, Class A surfaces such as B-pillars, bumpers, and exterior trim must be flawless. Even small defects like splay, read-through, short-shot, or ghosting can lead to rework, waste, or customer escalations.

These surfaces vary widely in finish, from high-gloss to textured matte, and subtle imperfections are often invisible to the human eye. Traditional inspection systems may catch some issues but lack the deeper insight needed to explain why they occur. Without visibility into the molding conditions behind the defect, root-cause prevention becomes difficult and costly.

Our Solution

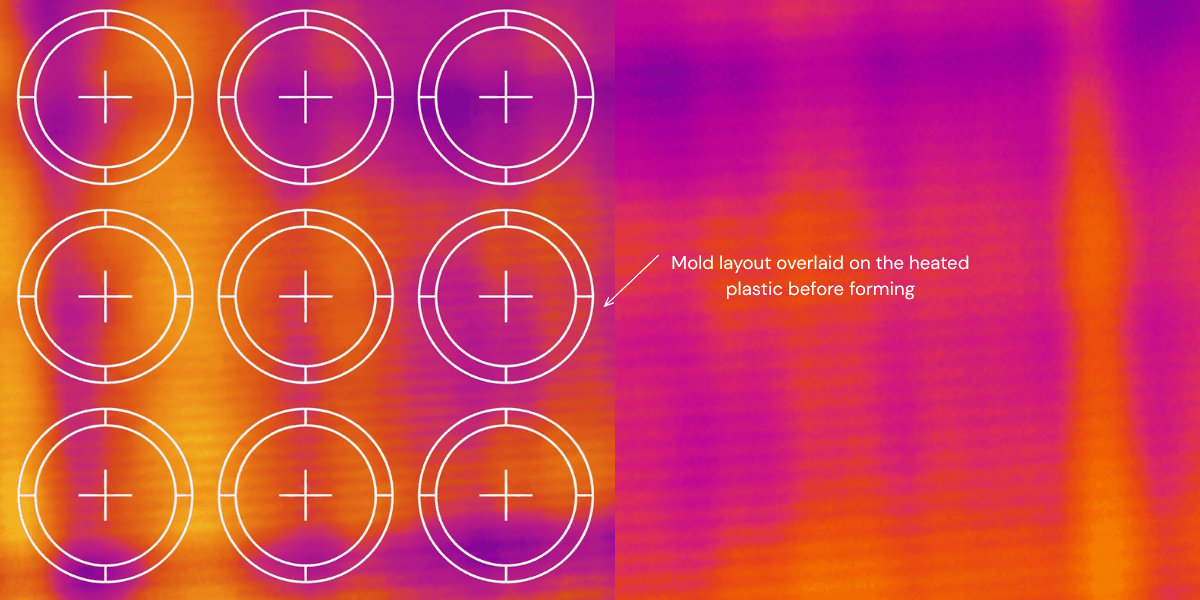

Eigen’s AI-powered machine vision system combines thermal and optical imaging with advanced illumination to reveal subtle surface defects that standard inspection cannot detect.

Specialized lighting and camera configurations create ideal conditions for highlighting variations in texture and reflection. OneView fuses these views into an enhanced surface map that makes anomalies stand out immediately.

In parallel, the system captures key process parameters such as injection pressure, fill time, hold time, cooling rate, and temperature profiles. Each part receives a unified digital record that links both image and process data. Machine learning models trained within OneView analyze this combined dataset in real time to detect defects, flag unusual patterns, and alert operators before parts move downstream.

Quality and process teams use this data to identify trends, improve consistency, and reduce the variation that leads to recurring defects.

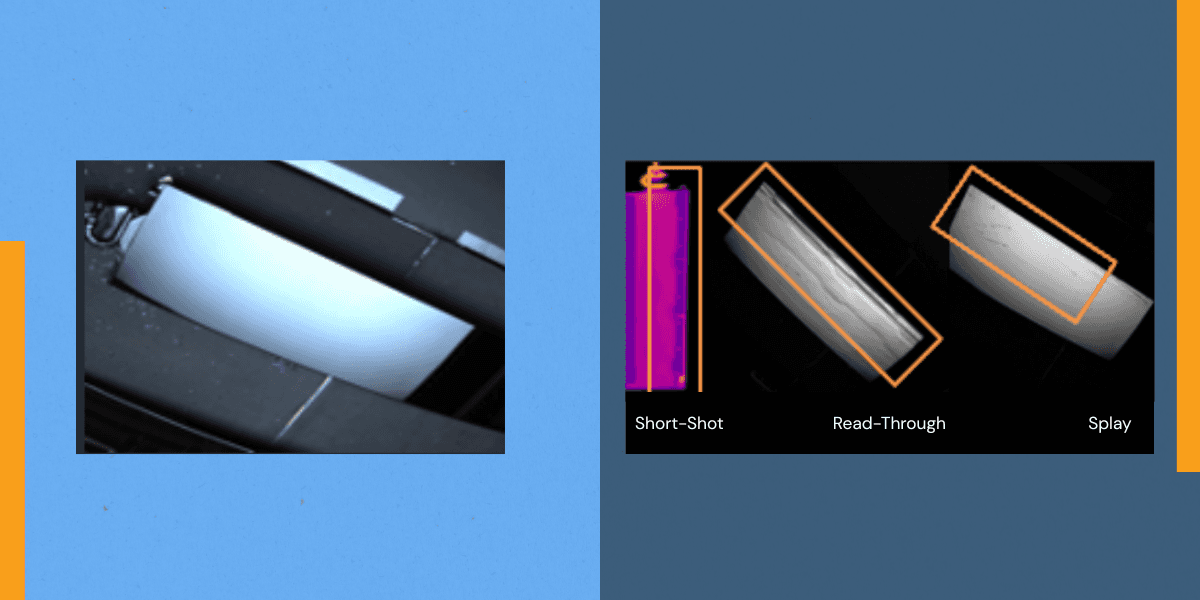

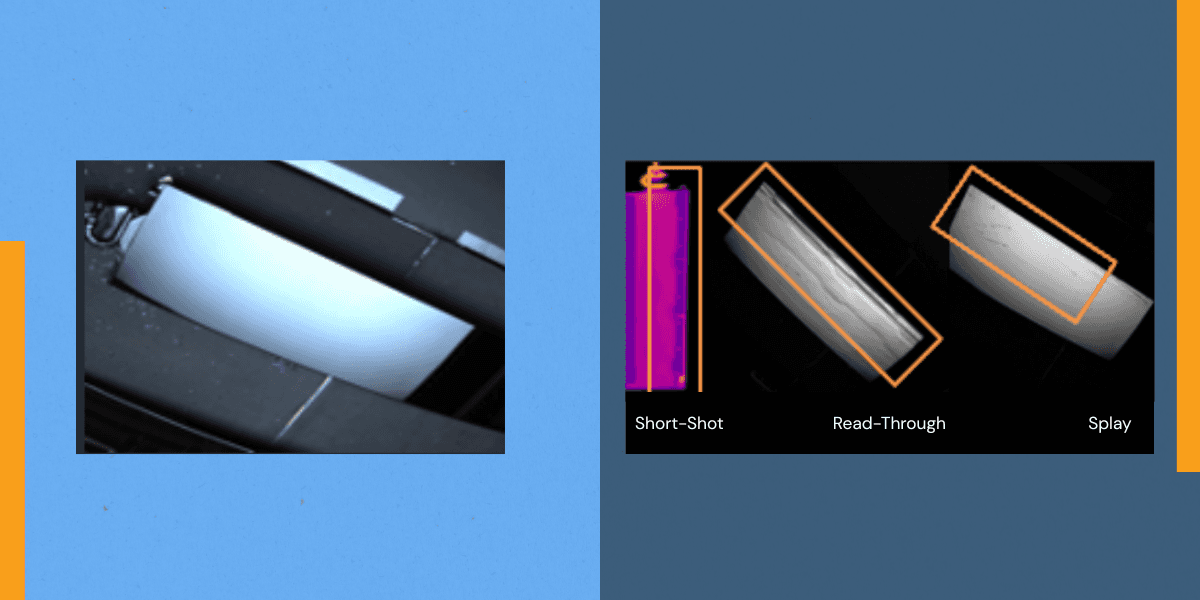

Operator view vs Eigen view

A side-by-side comparison of standard visual inspection and OneView’s fused thermal and optical imaging that makes short-shot, read-through, splay, and other subtle defects clearly visible.

Benefits

Defect Detection and Classification - Identifies and classifies surface defects such as short-shot, splay, read-through, flow lines, and ghosting, while linking them to process conditions that caused them.

Surface Mapping and Illumination Control - Optimized lighting enhances visibility across glossy and matte surfaces, enabling consistent inspection across different part geometries.

Integrated Process Data Capture - Each inspection is paired with cycle time, temperature, pressure, and cooling behavior, creating a complete digital history for every molded part.

Real-Time Monitoring and Alerts - Detects anomalies as they occur and notifies operators immediately, reducing the risk of defects moving downstream or reaching customers.

Analytics and Insight Generation - Transforms image and process data into insights that reveal recurring issues, correlate defects with machine or material variations, and support long-term quality improvement.

The Challenge

In automotive and appliance manufacturing, Class A surfaces such as B-pillars, bumpers, and exterior trim must be flawless. Even small defects like splay, read-through, short-shot, or ghosting can lead to rework, waste, or customer escalations.

These surfaces vary widely in finish, from high-gloss to textured matte, and subtle imperfections are often invisible to the human eye. Traditional inspection systems may catch some issues but lack the deeper insight needed to explain why they occur. Without visibility into the molding conditions behind the defect, root-cause prevention becomes difficult and costly.

Our Solution

Eigen’s AI-powered machine vision system combines thermal and optical imaging with advanced illumination to reveal subtle surface defects that standard inspection cannot detect.

Specialized lighting and camera configurations create ideal conditions for highlighting variations in texture and reflection. OneView fuses these views into an enhanced surface map that makes anomalies stand out immediately.

In parallel, the system captures key process parameters such as injection pressure, fill time, hold time, cooling rate, and temperature profiles. Each part receives a unified digital record that links both image and process data. Machine learning models trained within OneView analyze this combined dataset in real time to detect defects, flag unusual patterns, and alert operators before parts move downstream.

Quality and process teams use this data to identify trends, improve consistency, and reduce the variation that leads to recurring defects.

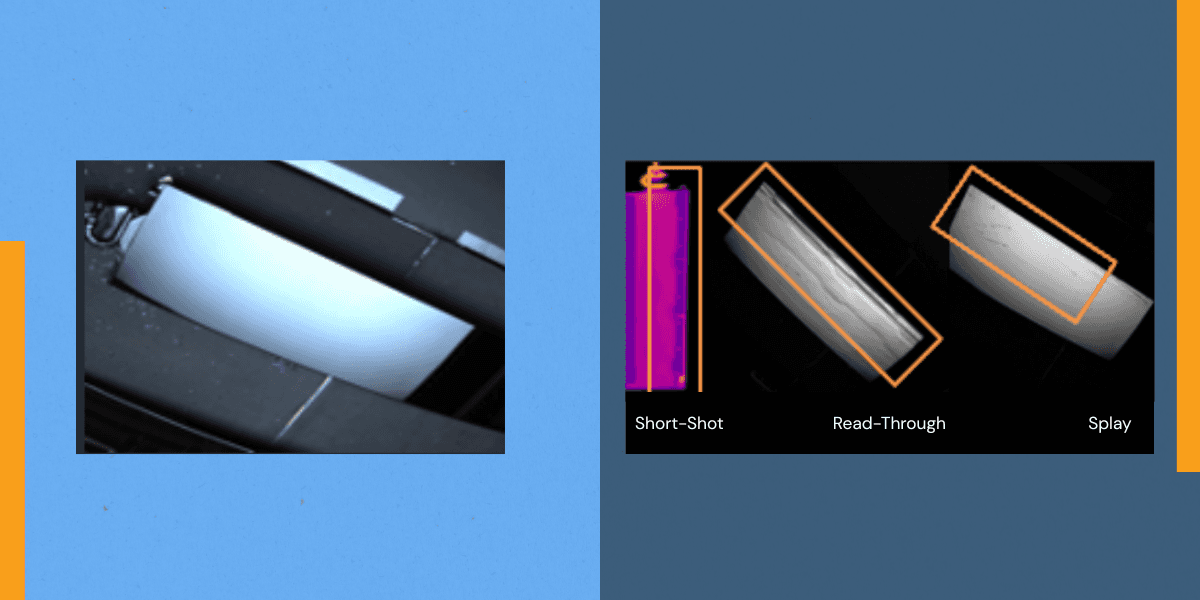

Operator view vs Eigen view

A side-by-side comparison of standard visual inspection and OneView’s fused thermal and optical imaging that makes short-shot, read-through, splay, and other subtle defects clearly visible.

Benefits

Defect Detection and Classification - Identifies and classifies surface defects such as short-shot, splay, read-through, flow lines, and ghosting, while linking them to process conditions that caused them.

Surface Mapping and Illumination Control - Optimized lighting enhances visibility across glossy and matte surfaces, enabling consistent inspection across different part geometries.

Integrated Process Data Capture - Each inspection is paired with cycle time, temperature, pressure, and cooling behavior, creating a complete digital history for every molded part.

Real-Time Monitoring and Alerts - Detects anomalies as they occur and notifies operators immediately, reducing the risk of defects moving downstream or reaching customers.

Analytics and Insight Generation - Transforms image and process data into insights that reveal recurring issues, correlate defects with machine or material variations, and support long-term quality improvement.

The Challenge

In automotive and appliance manufacturing, Class A surfaces such as B-pillars, bumpers, and exterior trim must be flawless. Even small defects like splay, read-through, short-shot, or ghosting can lead to rework, waste, or customer escalations.

These surfaces vary widely in finish, from high-gloss to textured matte, and subtle imperfections are often invisible to the human eye. Traditional inspection systems may catch some issues but lack the deeper insight needed to explain why they occur. Without visibility into the molding conditions behind the defect, root-cause prevention becomes difficult and costly.

Our Solution

Eigen’s AI-powered machine vision system combines thermal and optical imaging with advanced illumination to reveal subtle surface defects that standard inspection cannot detect.

Specialized lighting and camera configurations create ideal conditions for highlighting variations in texture and reflection. OneView fuses these views into an enhanced surface map that makes anomalies stand out immediately.

In parallel, the system captures key process parameters such as injection pressure, fill time, hold time, cooling rate, and temperature profiles. Each part receives a unified digital record that links both image and process data. Machine learning models trained within OneView analyze this combined dataset in real time to detect defects, flag unusual patterns, and alert operators before parts move downstream.

Quality and process teams use this data to identify trends, improve consistency, and reduce the variation that leads to recurring defects.

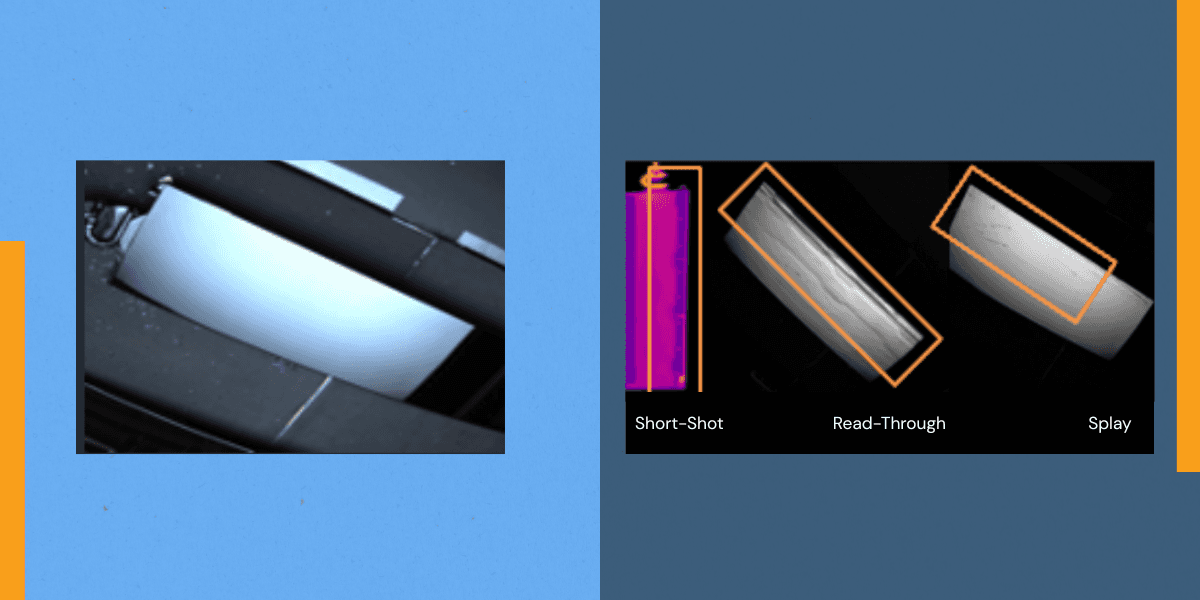

Operator view vs Eigen view

A side-by-side comparison of standard visual inspection and OneView’s fused thermal and optical imaging that makes short-shot, read-through, splay, and other subtle defects clearly visible.

Benefits

Defect Detection and Classification - Identifies and classifies surface defects such as short-shot, splay, read-through, flow lines, and ghosting, while linking them to process conditions that caused them.

Surface Mapping and Illumination Control - Optimized lighting enhances visibility across glossy and matte surfaces, enabling consistent inspection across different part geometries.

Integrated Process Data Capture - Each inspection is paired with cycle time, temperature, pressure, and cooling behavior, creating a complete digital history for every molded part.

Real-Time Monitoring and Alerts - Detects anomalies as they occur and notifies operators immediately, reducing the risk of defects moving downstream or reaching customers.

Analytics and Insight Generation - Transforms image and process data into insights that reveal recurring issues, correlate defects with machine or material variations, and support long-term quality improvement.

The Challenge

In automotive and appliance manufacturing, Class A surfaces such as B-pillars, bumpers, and exterior trim must be flawless. Even small defects like splay, read-through, short-shot, or ghosting can lead to rework, waste, or customer escalations.

These surfaces vary widely in finish, from high-gloss to textured matte, and subtle imperfections are often invisible to the human eye. Traditional inspection systems may catch some issues but lack the deeper insight needed to explain why they occur. Without visibility into the molding conditions behind the defect, root-cause prevention becomes difficult and costly.

Our Solution

Eigen’s AI-powered machine vision system combines thermal and optical imaging with advanced illumination to reveal subtle surface defects that standard inspection cannot detect.

Specialized lighting and camera configurations create ideal conditions for highlighting variations in texture and reflection. OneView fuses these views into an enhanced surface map that makes anomalies stand out immediately.

In parallel, the system captures key process parameters such as injection pressure, fill time, hold time, cooling rate, and temperature profiles. Each part receives a unified digital record that links both image and process data. Machine learning models trained within OneView analyze this combined dataset in real time to detect defects, flag unusual patterns, and alert operators before parts move downstream.

Quality and process teams use this data to identify trends, improve consistency, and reduce the variation that leads to recurring defects.

Operator view vs Eigen view

A side-by-side comparison of standard visual inspection and OneView’s fused thermal and optical imaging that makes short-shot, read-through, splay, and other subtle defects clearly visible.

Benefits

Defect Detection and Classification - Identifies and classifies surface defects such as short-shot, splay, read-through, flow lines, and ghosting, while linking them to process conditions that caused them.

Surface Mapping and Illumination Control - Optimized lighting enhances visibility across glossy and matte surfaces, enabling consistent inspection across different part geometries.

Integrated Process Data Capture - Each inspection is paired with cycle time, temperature, pressure, and cooling behavior, creating a complete digital history for every molded part.

Real-Time Monitoring and Alerts - Detects anomalies as they occur and notifies operators immediately, reducing the risk of defects moving downstream or reaching customers.

Analytics and Insight Generation - Transforms image and process data into insights that reveal recurring issues, correlate defects with machine or material variations, and support long-term quality improvement.

Read more

Injection Molding Inspection

Plastics

Real-time AI thermal and optical inspection that helps manufacturers detect surface defects early, understand their root causes, and protect Class A quality across every molded part.

Download

Sheet

Solution

Injection Molding Inspection