Food & Beverage

Temperature Monitoring

Real-time thermal inspection system that verifies product temperature and cooling consistency before packaging to protect shelf life and prevent quality escapes.

The Challenge

Maintaining proper product conditions before packaging is critical in baked goods production. Products that are packaged too hot or with excess surface moisture can cause condensation inside the package, increasing the risk of mold growth and accelerated spoilage.

Controlling product conditions prior to packaging is challenging. Traditional spot checks only sample a small portion of production and cannot provide continuous, product-by-product verification. As a result, temperature and cooling issues often go unnoticed, leading to reduced shelf life, customer complaints, product waste, and brand reputation risk.

Our Solution

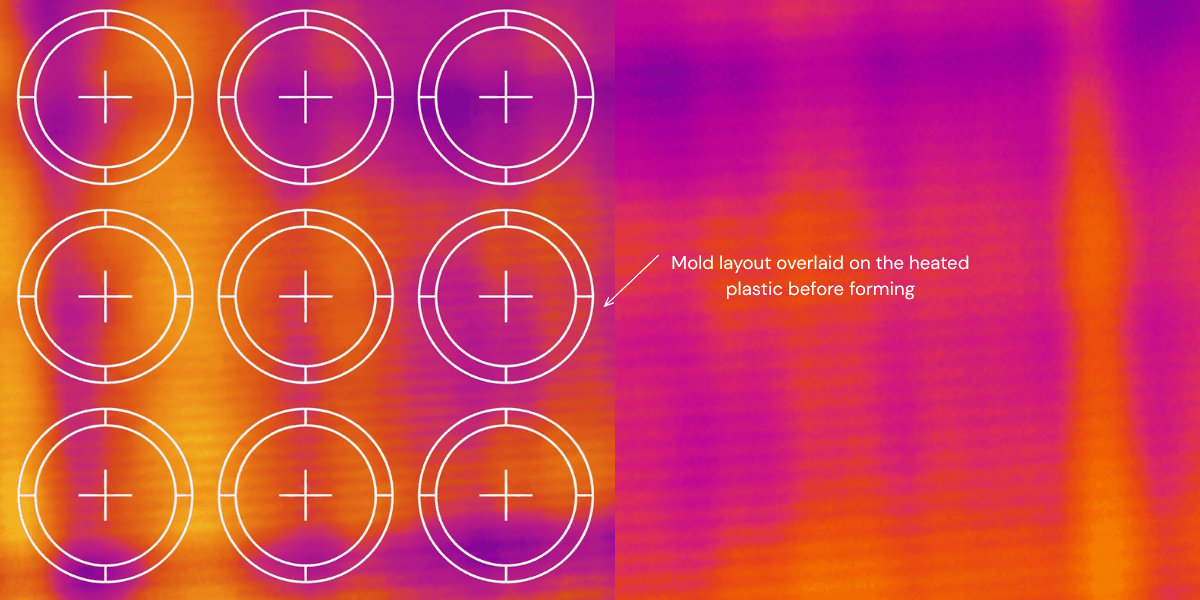

Eigen’s AI-powered food product monitoring solution uses thermal imaging and proprietary algorithms to continuously verify product temperature and cooling behavior inline, before packaging. The system automatically identifies each product, captures a complete surface temperature profile, and flags undesirable conditions in real time.

Thermal cameras monitor every item as it moves along the conveyor, allowing the system to detect products that exceed defined temperature thresholds or exhibit abnormal cooling patterns. By analyzing thermal signatures across the entire product surface, Eigen identifies inconsistencies that may indicate insufficient cooling time, airflow variability, or upstream process drift.

The solution goes beyond simple temperature checks by incorporating process context such as conveyor speed, cooling zone dwell time, ambient conditions, and line state. Within OneView, all inspection data is visualized, analyzed, and trended, making it easy for operators and quality teams to understand deviations and take action. When anomalies are detected, operators receive immediate alerts, preventing nonconforming products from being packaged. All inspection data is stored as a digital record, supporting traceability, root-cause analysis, and long-term process optimization.

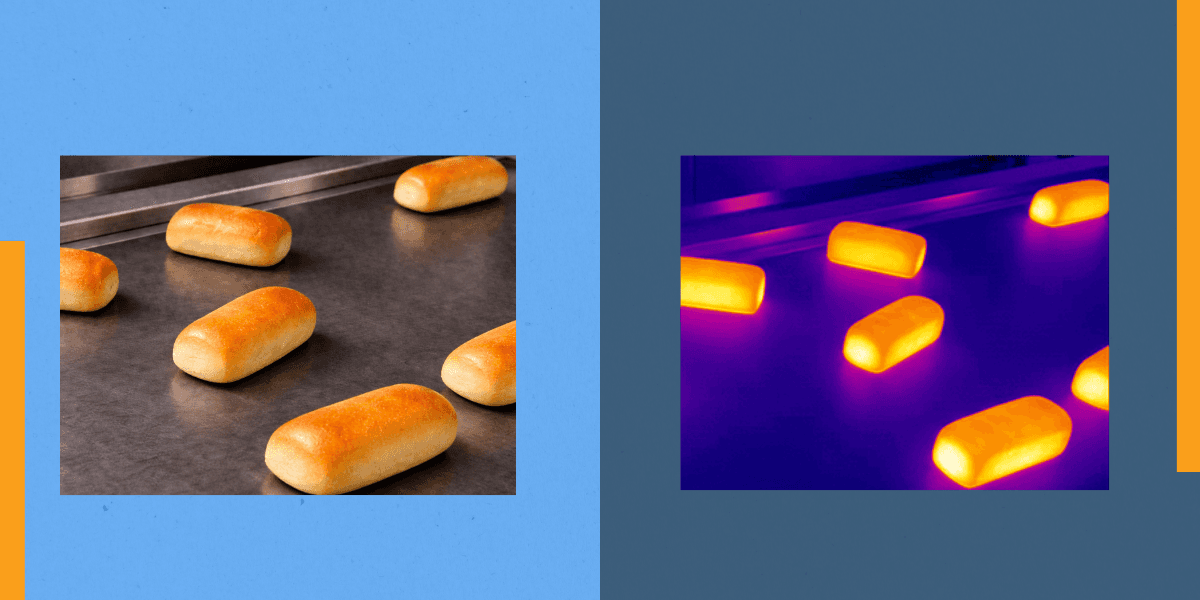

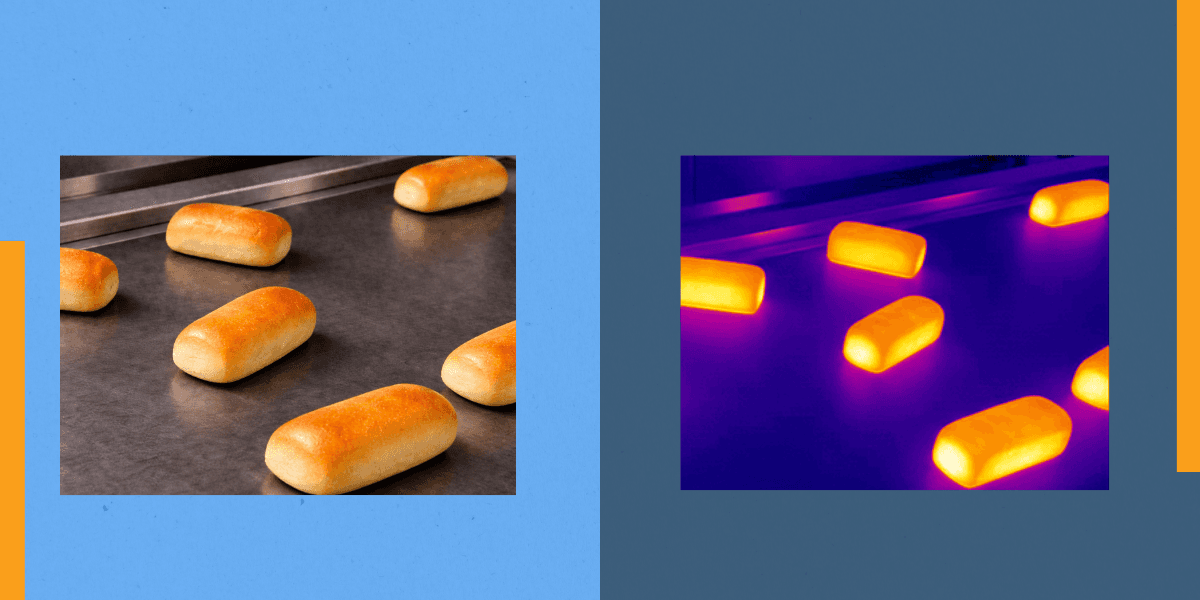

Operator view vs Eigen view

A side-by-side comparison showing how thermal imaging reveals product temperature and cooling.

Benefits

Improved Shelf Life Consistency: Ensures products are packaged only when they meet defined temperature and cooling requirements.

Continuous, Product-by-Product Verification: Monitors every item inline rather than relying on limited manual sampling.

Early Detection of Cooling Issues: Identifies uneven cooling, airflow problems, and process drift before quality is impacted.

Real-Time Operator Alerts: Flags temperature excursions immediately, enabling fast corrective action and preventing quality escapes.

Integrated Process Insight: Links thermal data with line speed, cooling time, and environmental conditions for deeper process understanding.

Traceability and Continuous Improvement: Stores inspection data in OneView to support audits, root-cause analysis, and ongoing optimization of cooling efficiency and product quality.

The Challenge

Maintaining proper product conditions before packaging is critical in baked goods production. Products that are packaged too hot or with excess surface moisture can cause condensation inside the package, increasing the risk of mold growth and accelerated spoilage.

Controlling product conditions prior to packaging is challenging. Traditional spot checks only sample a small portion of production and cannot provide continuous, product-by-product verification. As a result, temperature and cooling issues often go unnoticed, leading to reduced shelf life, customer complaints, product waste, and brand reputation risk.

Our Solution

Eigen’s AI-powered food product monitoring solution uses thermal imaging and proprietary algorithms to continuously verify product temperature and cooling behavior inline, before packaging. The system automatically identifies each product, captures a complete surface temperature profile, and flags undesirable conditions in real time.

Thermal cameras monitor every item as it moves along the conveyor, allowing the system to detect products that exceed defined temperature thresholds or exhibit abnormal cooling patterns. By analyzing thermal signatures across the entire product surface, Eigen identifies inconsistencies that may indicate insufficient cooling time, airflow variability, or upstream process drift.

The solution goes beyond simple temperature checks by incorporating process context such as conveyor speed, cooling zone dwell time, ambient conditions, and line state. Within OneView, all inspection data is visualized, analyzed, and trended, making it easy for operators and quality teams to understand deviations and take action. When anomalies are detected, operators receive immediate alerts, preventing nonconforming products from being packaged. All inspection data is stored as a digital record, supporting traceability, root-cause analysis, and long-term process optimization.

Operator view vs Eigen view

A side-by-side comparison showing how thermal imaging reveals product temperature and cooling.

Benefits

Improved Shelf Life Consistency: Ensures products are packaged only when they meet defined temperature and cooling requirements.

Continuous, Product-by-Product Verification: Monitors every item inline rather than relying on limited manual sampling.

Early Detection of Cooling Issues: Identifies uneven cooling, airflow problems, and process drift before quality is impacted.

Real-Time Operator Alerts: Flags temperature excursions immediately, enabling fast corrective action and preventing quality escapes.

Integrated Process Insight: Links thermal data with line speed, cooling time, and environmental conditions for deeper process understanding.

Traceability and Continuous Improvement: Stores inspection data in OneView to support audits, root-cause analysis, and ongoing optimization of cooling efficiency and product quality.

Temperature Monitoring

Food & Beverage

Real-time thermal inspection system that verifies product temperature and cooling consistency before packaging to protect shelf life and prevent quality escapes.

Download

Sheet

Solution

Temperature Monitoring