Food & Beverage

Package Sealing

Real-time thermal inspection system that detects weak or defective package seals immediately after sealing to prevent leaks, contamination, and shelf-life failures.

The Challenge

Seal integrity is one of the most critical quality factors in food packaging. Defects such as wrinkled film, particulates trapped in the seal, underheated or overheated seals, and folded film can create micro-channels or weak seal areas. These failures often lead to leaks, contamination, reduced shelf life, customer complaints, and recalls.

Many seal defects are subtle and difficult to detect using standard visual inspection, especially at high line speeds or when working with colored, reflective, or metallic films. As a result, defective seals frequently escape detection until downstream testing or distribution, driving product waste, rework, and brand risk.

Our Solution

Eigen’s AI-powered seal integrity inspection solution uses thermal imaging to inspect package seals immediately after sealing, while thermal contrast is still present. By capturing the heat distribution across each seal, the system reveals inconsistencies in seal formation that are invisible to conventional cameras.

Thermal cameras monitor every package inline, and proprietary AI models analyze the thermal profile of each seal to detect abnormal temperature patterns caused by insufficient heat, excess heat, wrinkled or folded film, or product contamination in the seal area. These conditions create distinct thermal signatures that indicate compromised seals before the package is cut or conveyed downstream.

Within OneView, seal regions are automatically identified and seal quality is classified in real time. Inspection results are evaluated against learned normal behavior and configurable thresholds. When defects are detected, immediate alerts are generated, enabling operators to adjust sealing parameters, correct film handling issues, or trigger automation such as rejecting defective packages or stopping the line before large volumes of nonconforming product are produced. All inspection results are stored as a digital record, supporting traceability, root-cause analysis, and continuous seal optimization.

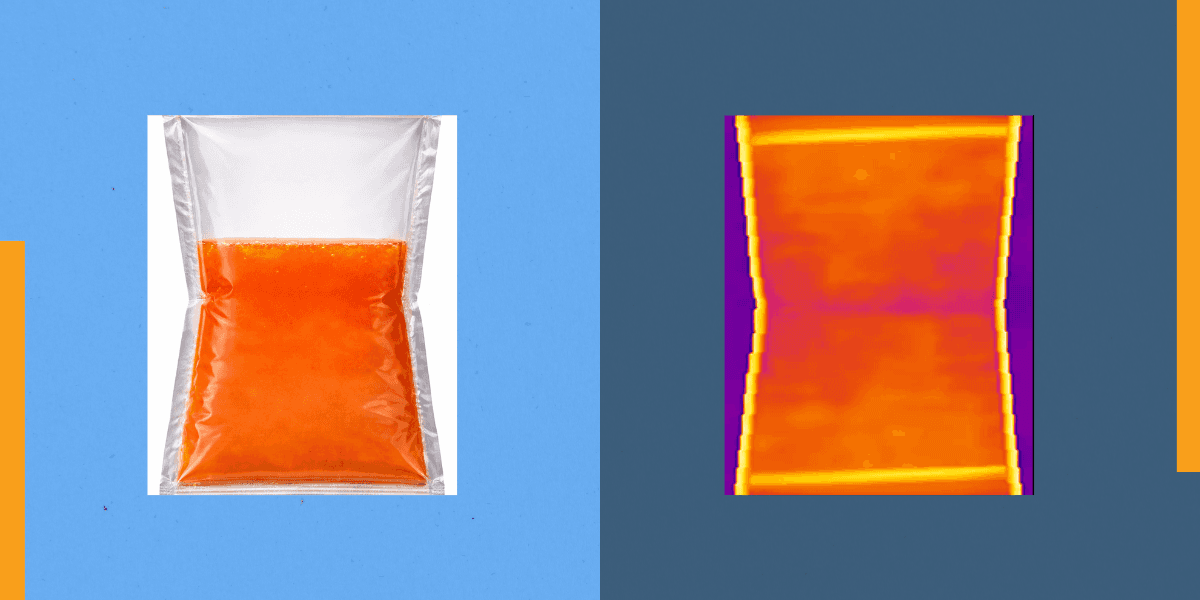

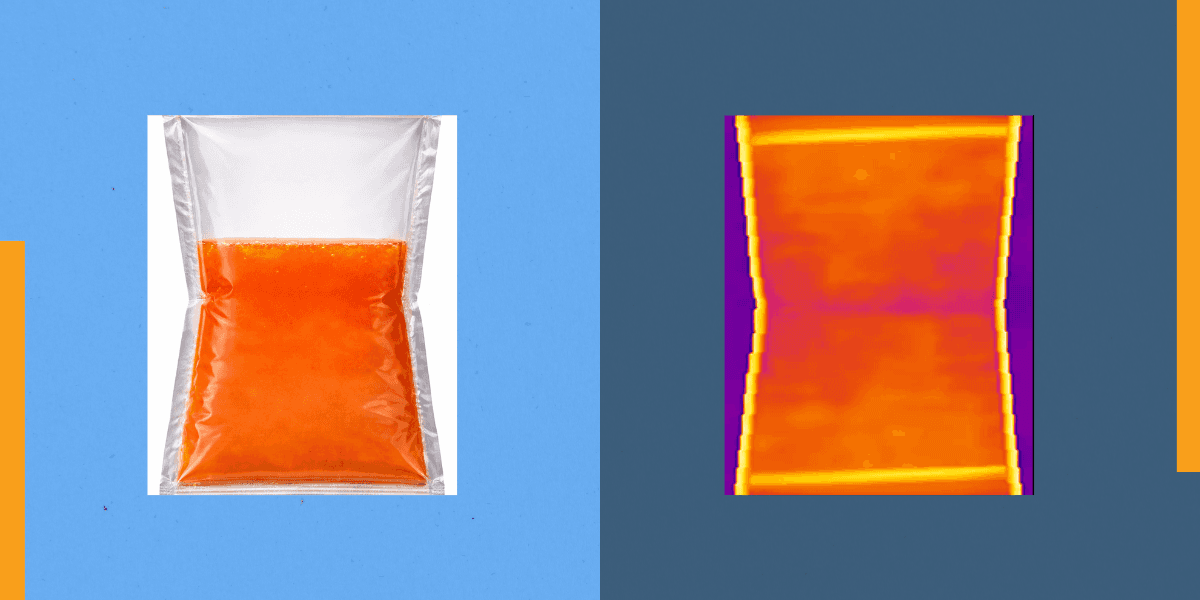

Operator view vs Eigen view

A side-by-side comparison demonstrating a uniform thermal seal profile that confirms seal integrity beyond visual inspection.

Benefits

Improved Seal Reliability: Detects weak or compromised seals before packages move downstream, reducing leaks and contamination.

Early Detection of Subtle Defects: Identifies wrinkled film, particulates in the seal, underheated and overheated seals, and folded film that often escape visual inspection.

Real-Time Operator Alerts: Flags seal defects as they occur, enabling immediate corrective action and reducing product waste.

Flexible and Configurable Inspection: Supports adjustable thresholds and severity settings to adapt easily to new SKUs, materials, and packaging formats.

Data-Driven Seal Optimization: Aggregates inspection data to identify recurring issues, correlate defects with machine settings or material changes, and improve sealing consistency over time.

Traceability and Compliance Support: Stores inspection results as a digital record to support

audits, root-cause analysis, and continuous improvement initiatives.

The Challenge

Seal integrity is one of the most critical quality factors in food packaging. Defects such as wrinkled film, particulates trapped in the seal, underheated or overheated seals, and folded film can create micro-channels or weak seal areas. These failures often lead to leaks, contamination, reduced shelf life, customer complaints, and recalls.

Many seal defects are subtle and difficult to detect using standard visual inspection, especially at high line speeds or when working with colored, reflective, or metallic films. As a result, defective seals frequently escape detection until downstream testing or distribution, driving product waste, rework, and brand risk.

Our Solution

Eigen’s AI-powered seal integrity inspection solution uses thermal imaging to inspect package seals immediately after sealing, while thermal contrast is still present. By capturing the heat distribution across each seal, the system reveals inconsistencies in seal formation that are invisible to conventional cameras.

Thermal cameras monitor every package inline, and proprietary AI models analyze the thermal profile of each seal to detect abnormal temperature patterns caused by insufficient heat, excess heat, wrinkled or folded film, or product contamination in the seal area. These conditions create distinct thermal signatures that indicate compromised seals before the package is cut or conveyed downstream.

Within OneView, seal regions are automatically identified and seal quality is classified in real time. Inspection results are evaluated against learned normal behavior and configurable thresholds. When defects are detected, immediate alerts are generated, enabling operators to adjust sealing parameters, correct film handling issues, or trigger automation such as rejecting defective packages or stopping the line before large volumes of nonconforming product are produced. All inspection results are stored as a digital record, supporting traceability, root-cause analysis, and continuous seal optimization.

Operator view vs Eigen view

A side-by-side comparison demonstrating a uniform thermal seal profile that confirms seal integrity beyond visual inspection.

Benefits

Improved Seal Reliability: Detects weak or compromised seals before packages move downstream, reducing leaks and contamination.

Early Detection of Subtle Defects: Identifies wrinkled film, particulates in the seal, underheated and overheated seals, and folded film that often escape visual inspection.

Real-Time Operator Alerts: Flags seal defects as they occur, enabling immediate corrective action and reducing product waste.

Flexible and Configurable Inspection: Supports adjustable thresholds and severity settings to adapt easily to new SKUs, materials, and packaging formats.

Data-Driven Seal Optimization: Aggregates inspection data to identify recurring issues, correlate defects with machine settings or material changes, and improve sealing consistency over time.

Traceability and Compliance Support: Stores inspection results as a digital record to support

audits, root-cause analysis, and continuous improvement initiatives.

Read more

Package Sealing

Food & Beverage

Real-time thermal inspection system that detects weak or defective package seals immediately after sealing to prevent leaks, contamination, and shelf-life failures.

Download

Sheet

Solution

Package Sealing