Metals

Furnace Wall Monitoring

Real-time thermal monitoring system that detects abnormal furnace wall heating early to reduce breakout risk, protect equipment, and improve operator safety.

The Challenge

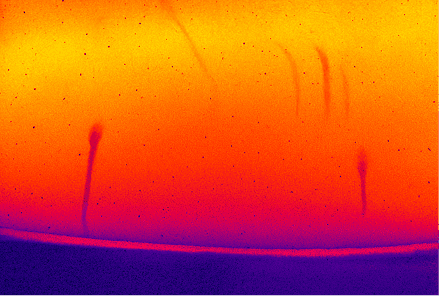

Furnace walls must maintain stable temperatures to ensure safe and predictable melting conditions. Rapid temperature spikes along the wall surface can indicate early signs of iron breakout risk, failures in cooling water flow, or hotspots caused by structural degradation.

If left undetected, these conditions can escalate quickly, leading to wall damage, serious safety hazards, and unplanned shutdowns. Operators need early, reliable visibility into wall temperature behavior to intervene before conditions become critical.

Our Solution

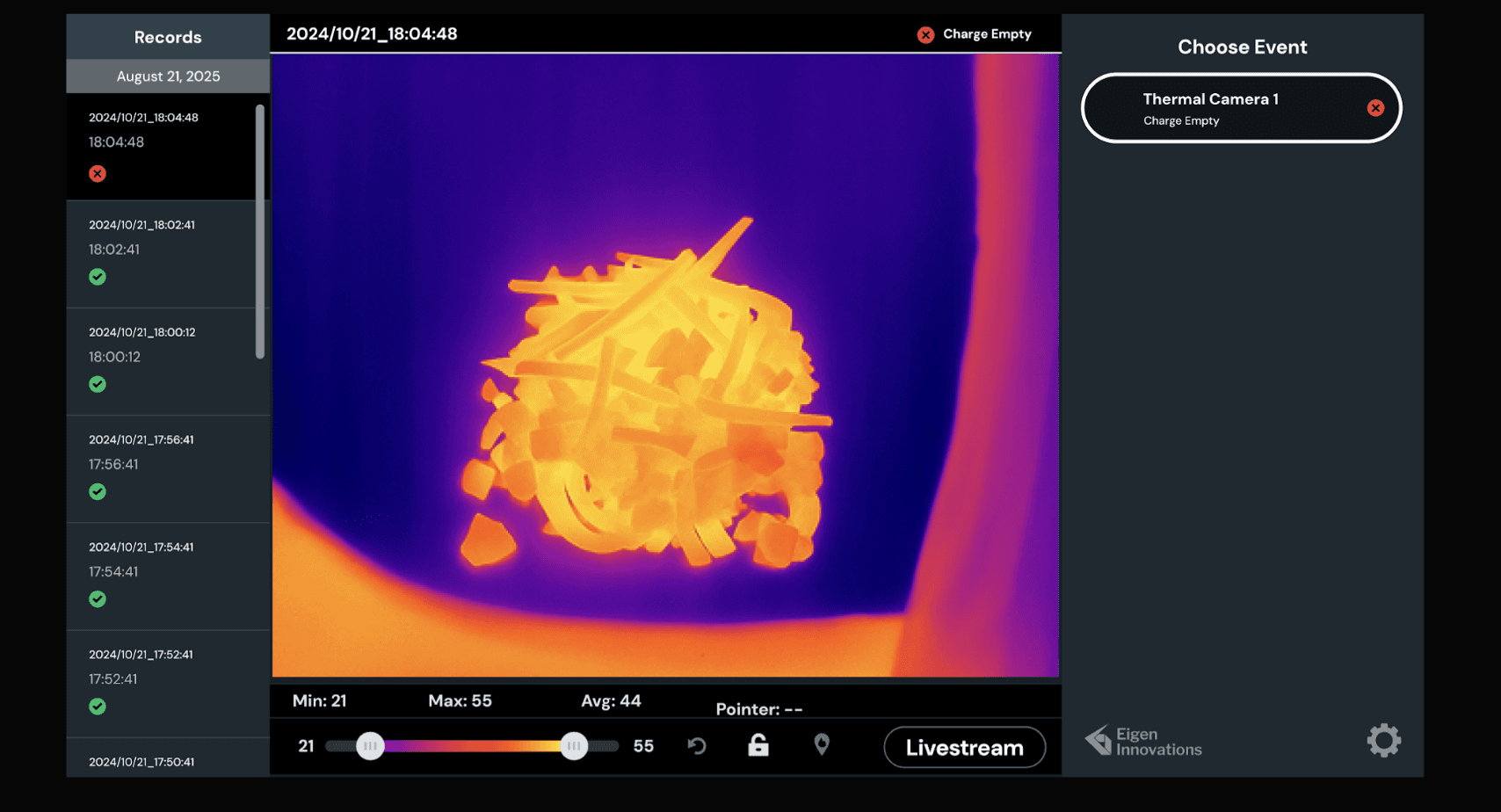

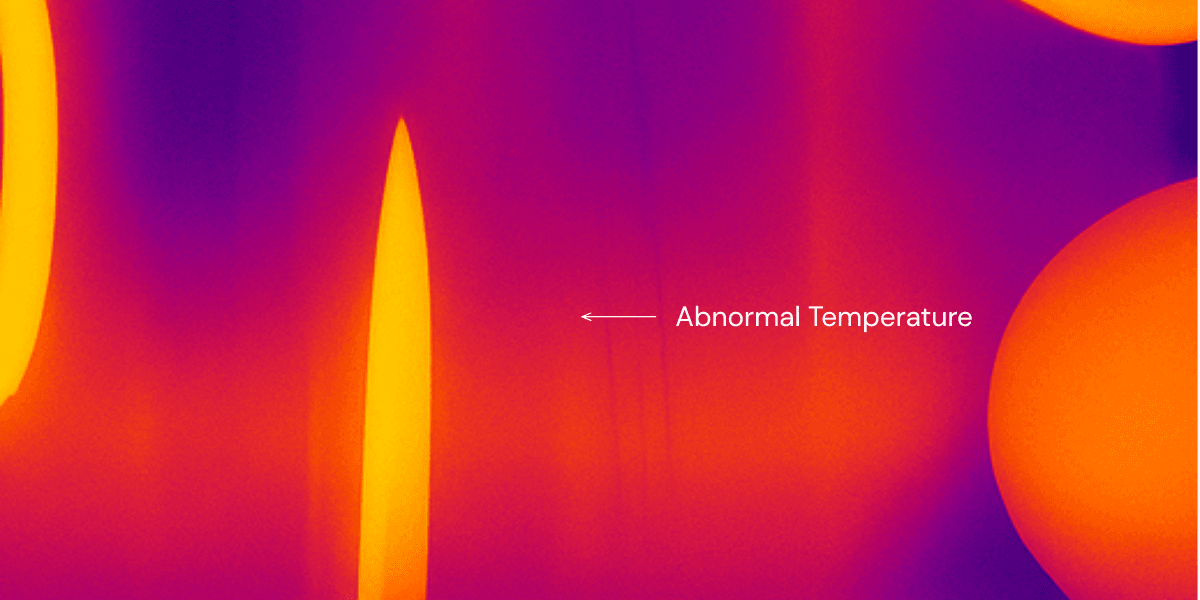

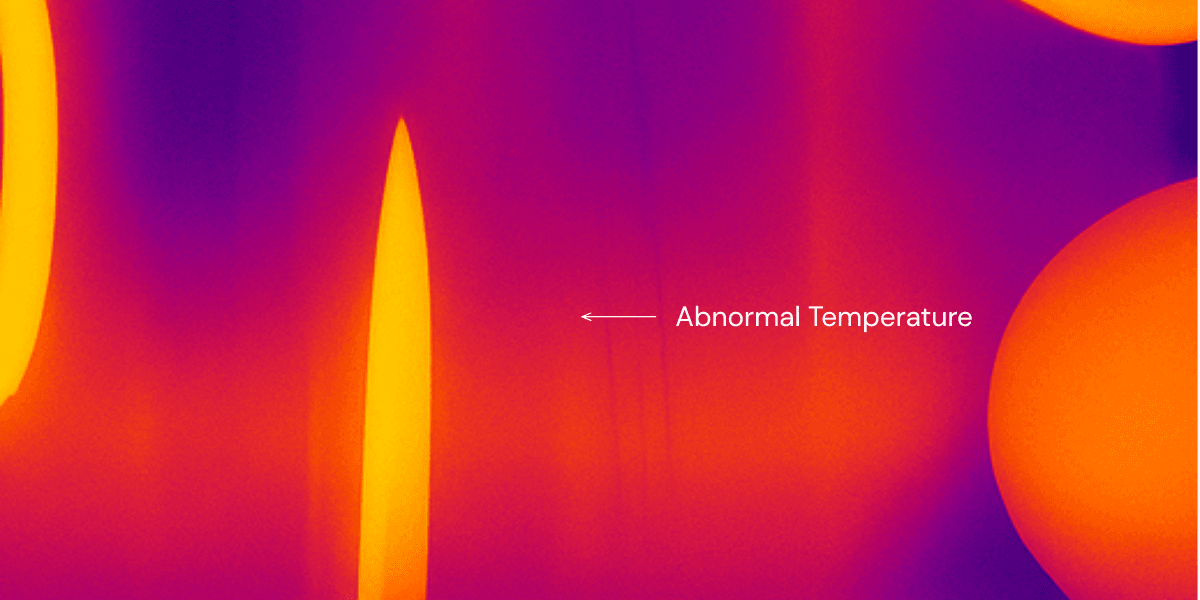

Eigen’s AI-powered furnace wall monitoring solution continuously measures temperature distribution across the furnace wall to detect abnormal heating in real time. By analyzing thermal signatures from one or multiple camera views, OneView identifies emerging hotspots and classifies wall conditions before failures occur.

When unusual heating is detected, the system immediately alerts operators through the melt-station HMI and light stack, providing advance warning and time to take corrective action. Thermal data is continuously analyzed to distinguish between normal operating variation and conditions that require attention, helping crews focus on true risks rather than noise.

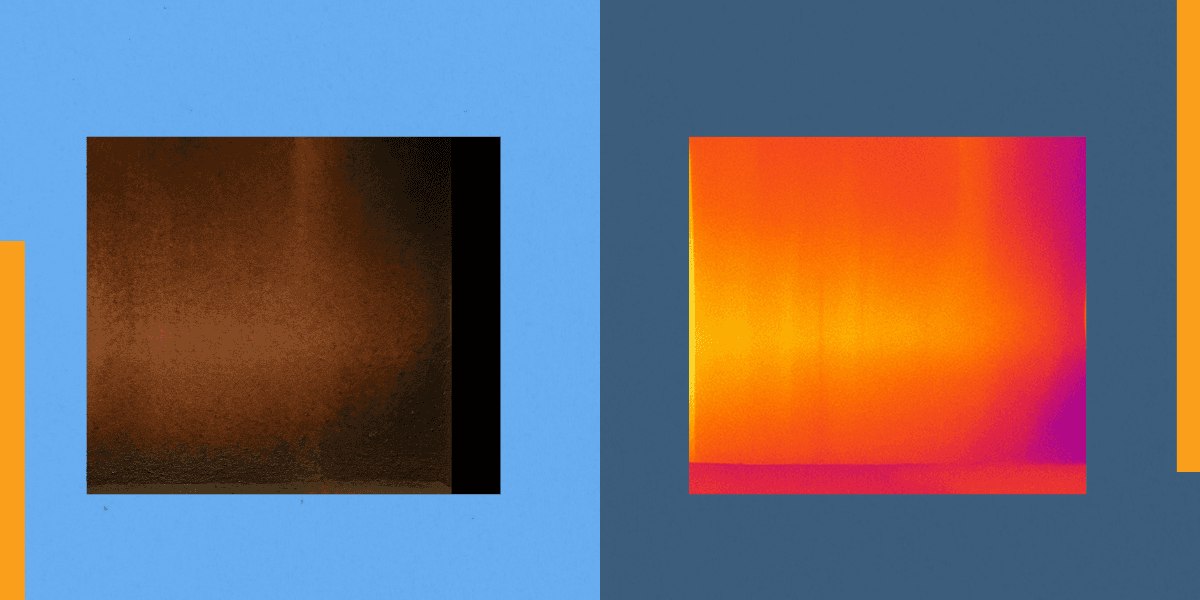

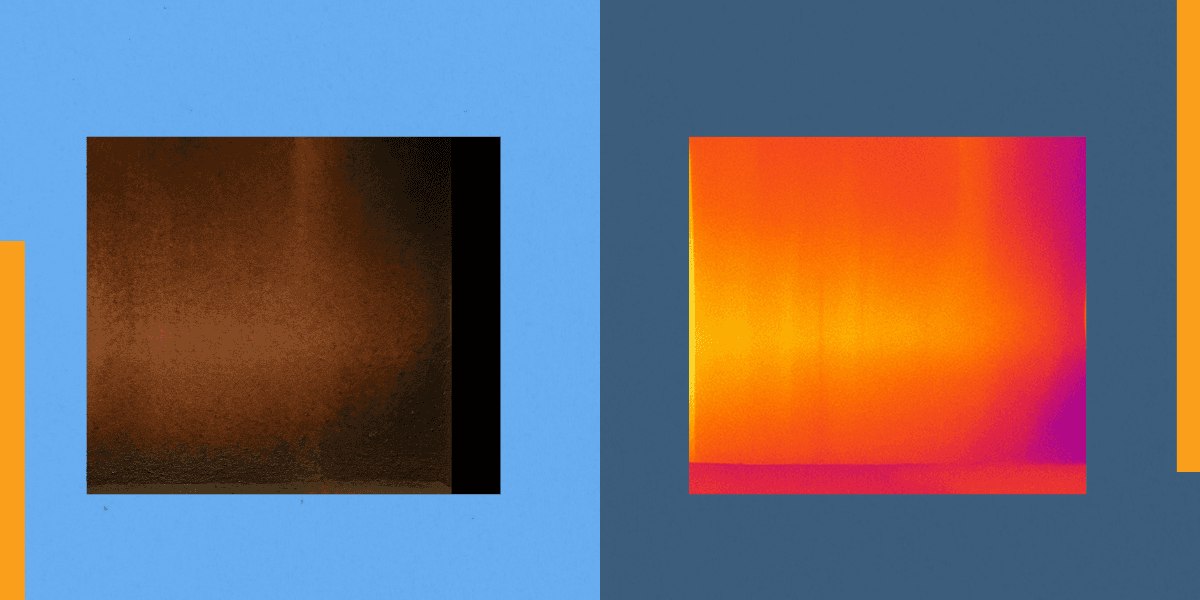

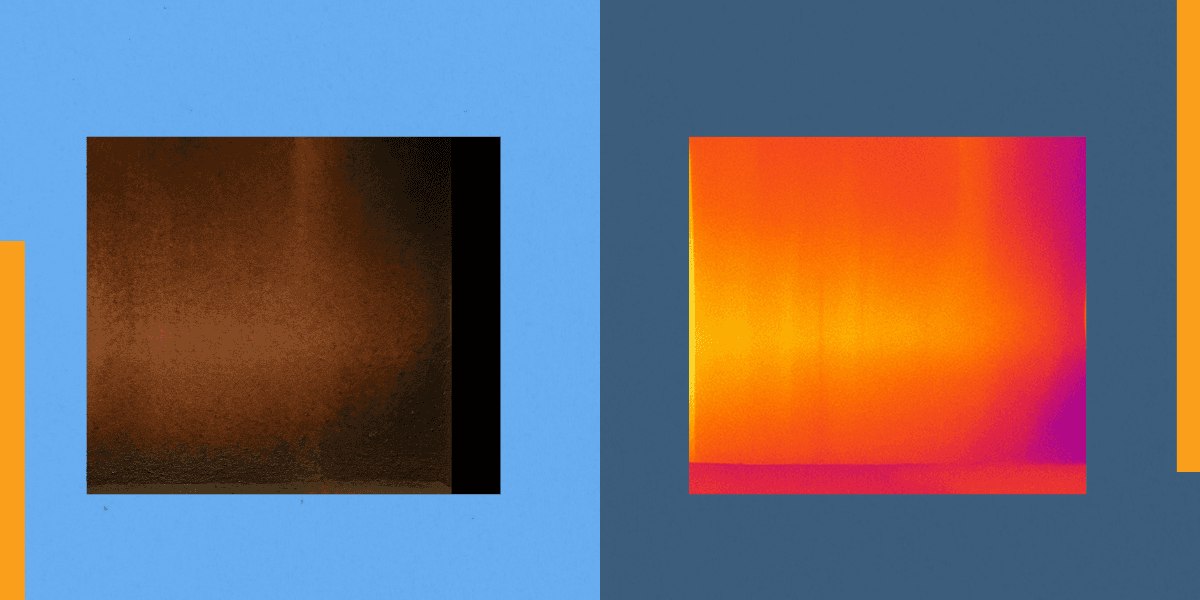

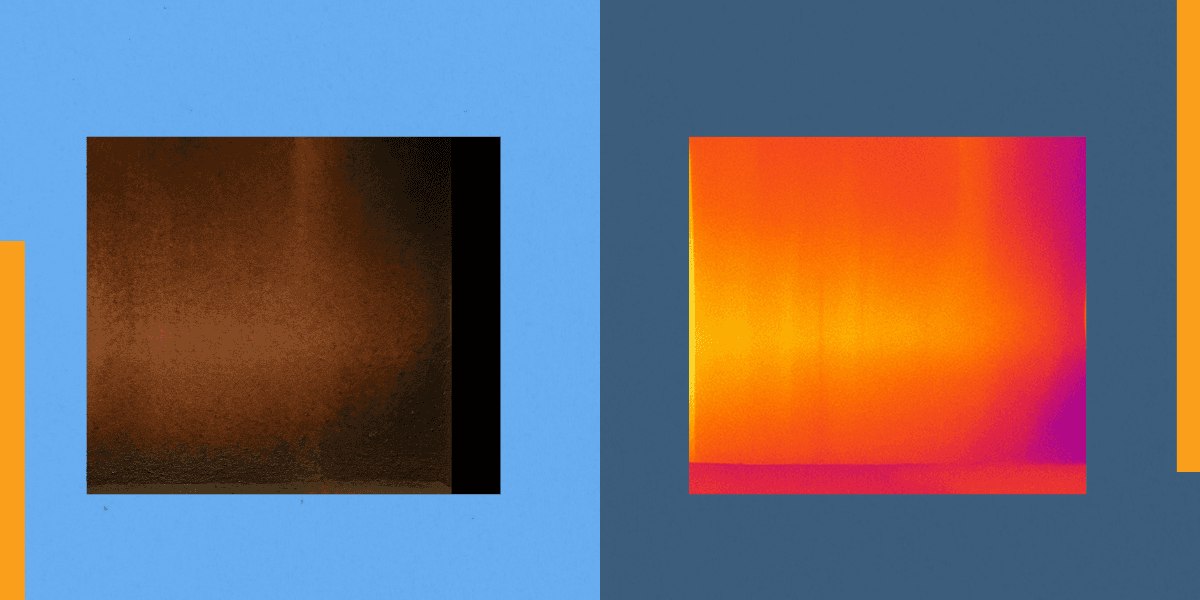

Operator view vs Eigen view

A side-by-side comparison illustrating normal furnace wall temperature distribution during stable operation.

Benefits

Early Breakout Risk Detection: Identifies localized temperature spikes that may indicate thinning walls, cooling failures, or structural degradation.

Improved Furnace Safety: Provides operators with early warnings before wall conditions escalate into safety-critical events.

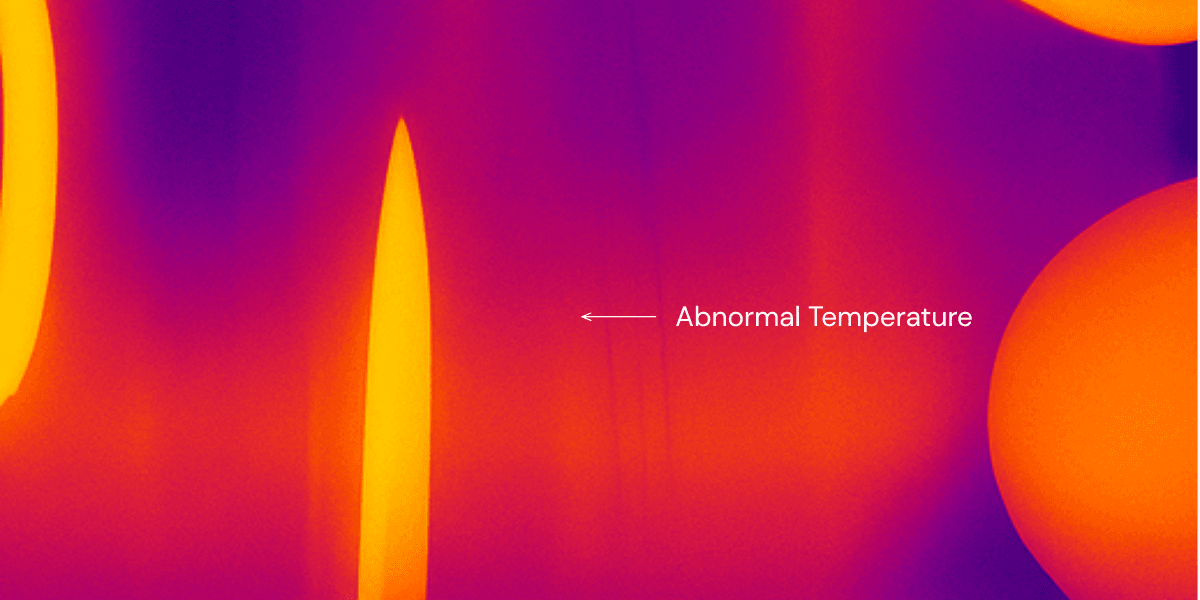

Clear Wall Health Classification: Categorizes conditions as Normal Temperature, Abnormal Temperature, or Fault for fast, confident decision-making.

Continuous Thermal Trend Tracking: Monitors wall temperature over time to detect gradual heating patterns that may precede failure.

Real-Time Operator Alerts: Delivers immediate notifications at the melt station via HMI and light stacks for rapid response.

Reduced Downtime and Damage: Enables proactive maintenance and intervention, helping avoid unplanned shutdowns and costly repairs.

The Challenge

Furnace walls must maintain stable temperatures to ensure safe and predictable melting conditions. Rapid temperature spikes along the wall surface can indicate early signs of iron breakout risk, failures in cooling water flow, or hotspots caused by structural degradation.

If left undetected, these conditions can escalate quickly, leading to wall damage, serious safety hazards, and unplanned shutdowns. Operators need early, reliable visibility into wall temperature behavior to intervene before conditions become critical.

Our Solution

Eigen’s AI-powered furnace wall monitoring solution continuously measures temperature distribution across the furnace wall to detect abnormal heating in real time. By analyzing thermal signatures from one or multiple camera views, OneView identifies emerging hotspots and classifies wall conditions before failures occur.

When unusual heating is detected, the system immediately alerts operators through the melt-station HMI and light stack, providing advance warning and time to take corrective action. Thermal data is continuously analyzed to distinguish between normal operating variation and conditions that require attention, helping crews focus on true risks rather than noise.

Operator view vs Eigen view

A side-by-side comparison illustrating normal furnace wall temperature distribution during stable operation.

Benefits

Early Breakout Risk Detection: Identifies localized temperature spikes that may indicate thinning walls, cooling failures, or structural degradation.

Improved Furnace Safety: Provides operators with early warnings before wall conditions escalate into safety-critical events.

Clear Wall Health Classification: Categorizes conditions as Normal Temperature, Abnormal Temperature, or Fault for fast, confident decision-making.

Continuous Thermal Trend Tracking: Monitors wall temperature over time to detect gradual heating patterns that may precede failure.

Real-Time Operator Alerts: Delivers immediate notifications at the melt station via HMI and light stacks for rapid response.

Reduced Downtime and Damage: Enables proactive maintenance and intervention, helping avoid unplanned shutdowns and costly repairs.

The Challenge

Furnace walls must maintain stable temperatures to ensure safe and predictable melting conditions. Rapid temperature spikes along the wall surface can indicate early signs of iron breakout risk, failures in cooling water flow, or hotspots caused by structural degradation.

If left undetected, these conditions can escalate quickly, leading to wall damage, serious safety hazards, and unplanned shutdowns. Operators need early, reliable visibility into wall temperature behavior to intervene before conditions become critical.

Our Solution

Eigen’s AI-powered furnace wall monitoring solution continuously measures temperature distribution across the furnace wall to detect abnormal heating in real time. By analyzing thermal signatures from one or multiple camera views, OneView identifies emerging hotspots and classifies wall conditions before failures occur.

When unusual heating is detected, the system immediately alerts operators through the melt-station HMI and light stack, providing advance warning and time to take corrective action. Thermal data is continuously analyzed to distinguish between normal operating variation and conditions that require attention, helping crews focus on true risks rather than noise.

Operator view vs Eigen view

A side-by-side comparison illustrating normal furnace wall temperature distribution during stable operation.

Benefits

Early Breakout Risk Detection: Identifies localized temperature spikes that may indicate thinning walls, cooling failures, or structural degradation.

Improved Furnace Safety: Provides operators with early warnings before wall conditions escalate into safety-critical events.

Clear Wall Health Classification: Categorizes conditions as Normal Temperature, Abnormal Temperature, or Fault for fast, confident decision-making.

Continuous Thermal Trend Tracking: Monitors wall temperature over time to detect gradual heating patterns that may precede failure.

Real-Time Operator Alerts: Delivers immediate notifications at the melt station via HMI and light stacks for rapid response.

Reduced Downtime and Damage: Enables proactive maintenance and intervention, helping avoid unplanned shutdowns and costly repairs.

The Challenge

Furnace walls must maintain stable temperatures to ensure safe and predictable melting conditions. Rapid temperature spikes along the wall surface can indicate early signs of iron breakout risk, failures in cooling water flow, or hotspots caused by structural degradation.

If left undetected, these conditions can escalate quickly, leading to wall damage, serious safety hazards, and unplanned shutdowns. Operators need early, reliable visibility into wall temperature behavior to intervene before conditions become critical.

Our Solution

Eigen’s AI-powered furnace wall monitoring solution continuously measures temperature distribution across the furnace wall to detect abnormal heating in real time. By analyzing thermal signatures from one or multiple camera views, OneView identifies emerging hotspots and classifies wall conditions before failures occur.

When unusual heating is detected, the system immediately alerts operators through the melt-station HMI and light stack, providing advance warning and time to take corrective action. Thermal data is continuously analyzed to distinguish between normal operating variation and conditions that require attention, helping crews focus on true risks rather than noise.

Operator view vs Eigen view

A side-by-side comparison illustrating normal furnace wall temperature distribution during stable operation.

Benefits

Early Breakout Risk Detection: Identifies localized temperature spikes that may indicate thinning walls, cooling failures, or structural degradation.

Improved Furnace Safety: Provides operators with early warnings before wall conditions escalate into safety-critical events.

Clear Wall Health Classification: Categorizes conditions as Normal Temperature, Abnormal Temperature, or Fault for fast, confident decision-making.

Continuous Thermal Trend Tracking: Monitors wall temperature over time to detect gradual heating patterns that may precede failure.

Real-Time Operator Alerts: Delivers immediate notifications at the melt station via HMI and light stacks for rapid response.

Reduced Downtime and Damage: Enables proactive maintenance and intervention, helping avoid unplanned shutdowns and costly repairs.

Read more

Furnace Wall Monitoring

Metals

Real-time thermal monitoring system that detects abnormal furnace wall heating early to reduce breakout risk, protect equipment, and improve operator safety.

Download

Sheet

Solution

Furnace Wall Monitoring