Metals

Fill Level Monitoring

Real-time thermal monitoring system that estimates charge height and alerts operators before refill thresholds are missed, improving melt stability and reducing charging disruptions.

The Challenge

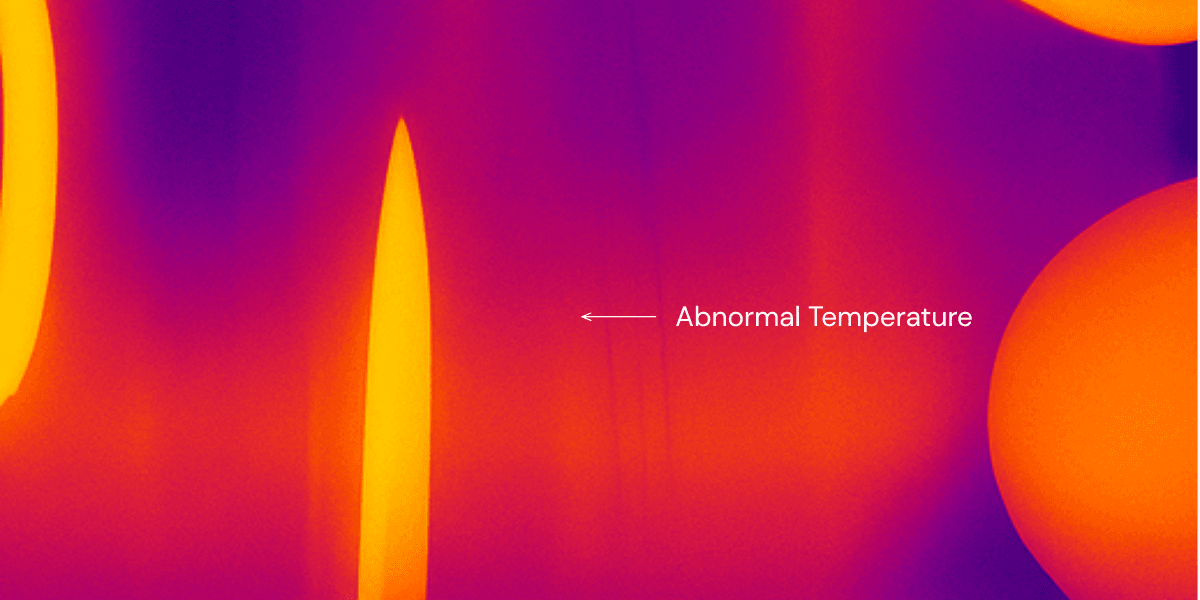

In cupola furnace operations, maintaining the correct charge height is critical for stable melting and consistent iron output. Abnormal behavior in how the charge bed rises, settles, or heats can signal issues such as bridging, hang-ups, uneven charging, or irregular melt rates.

If these conditions go undetected, they can lead to melt-quality variation, reduced energy efficiency, and unplanned disruptions to charging cycles. By ensuring the charge level does not drop below the desired threshold, operators can maintain consistent feed rates and keep cupola performance stable and efficient.

Our Solution

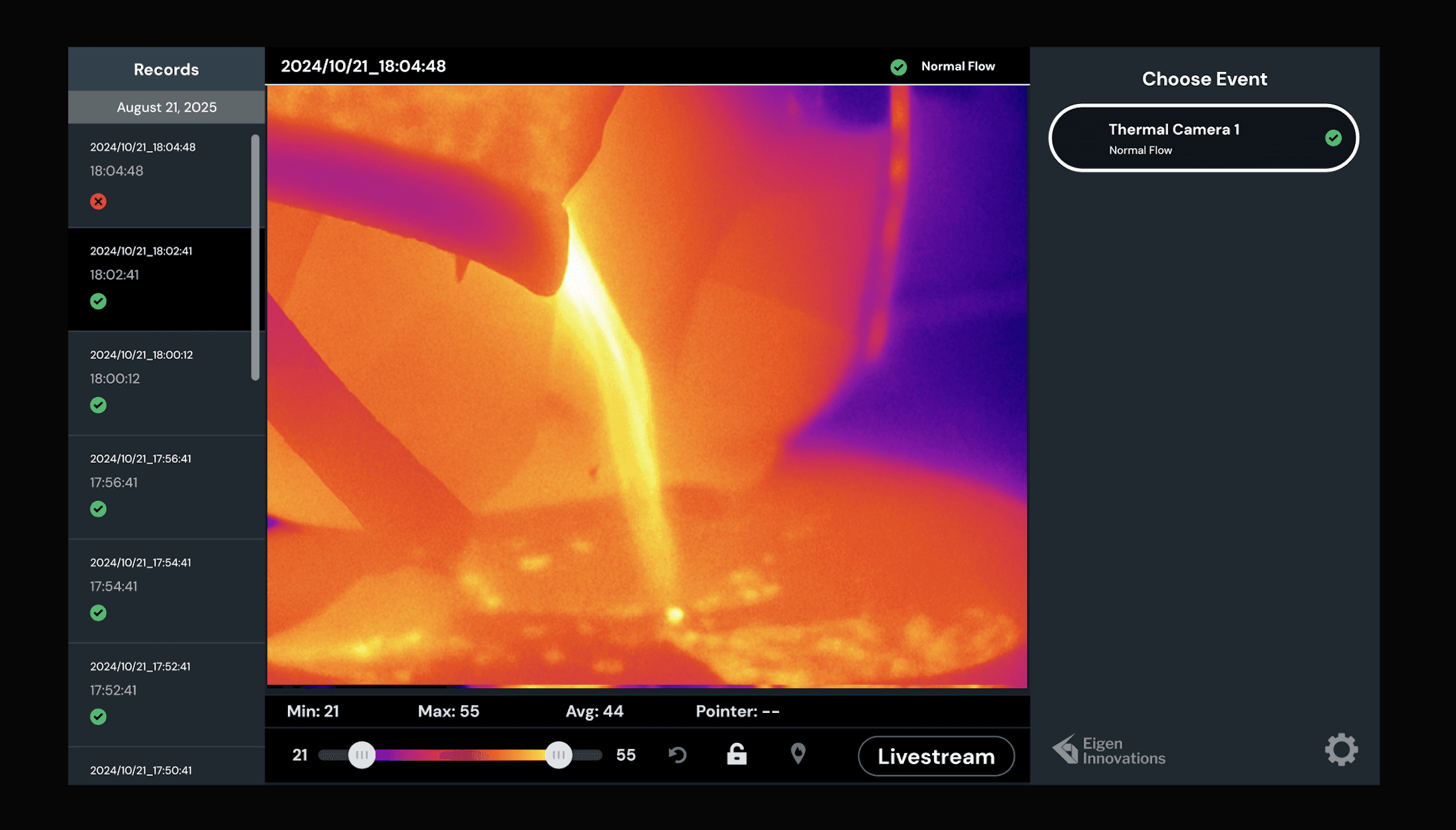

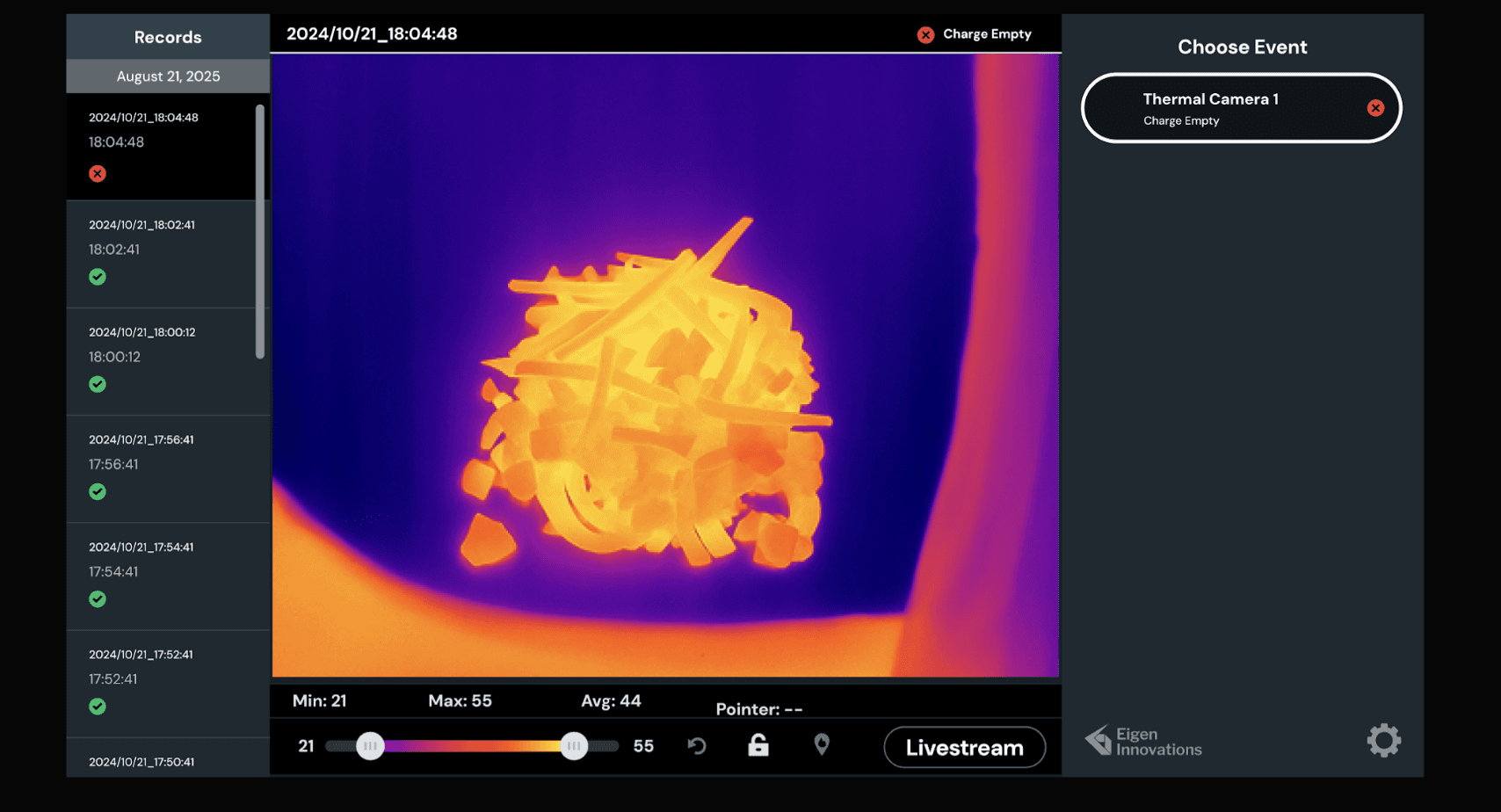

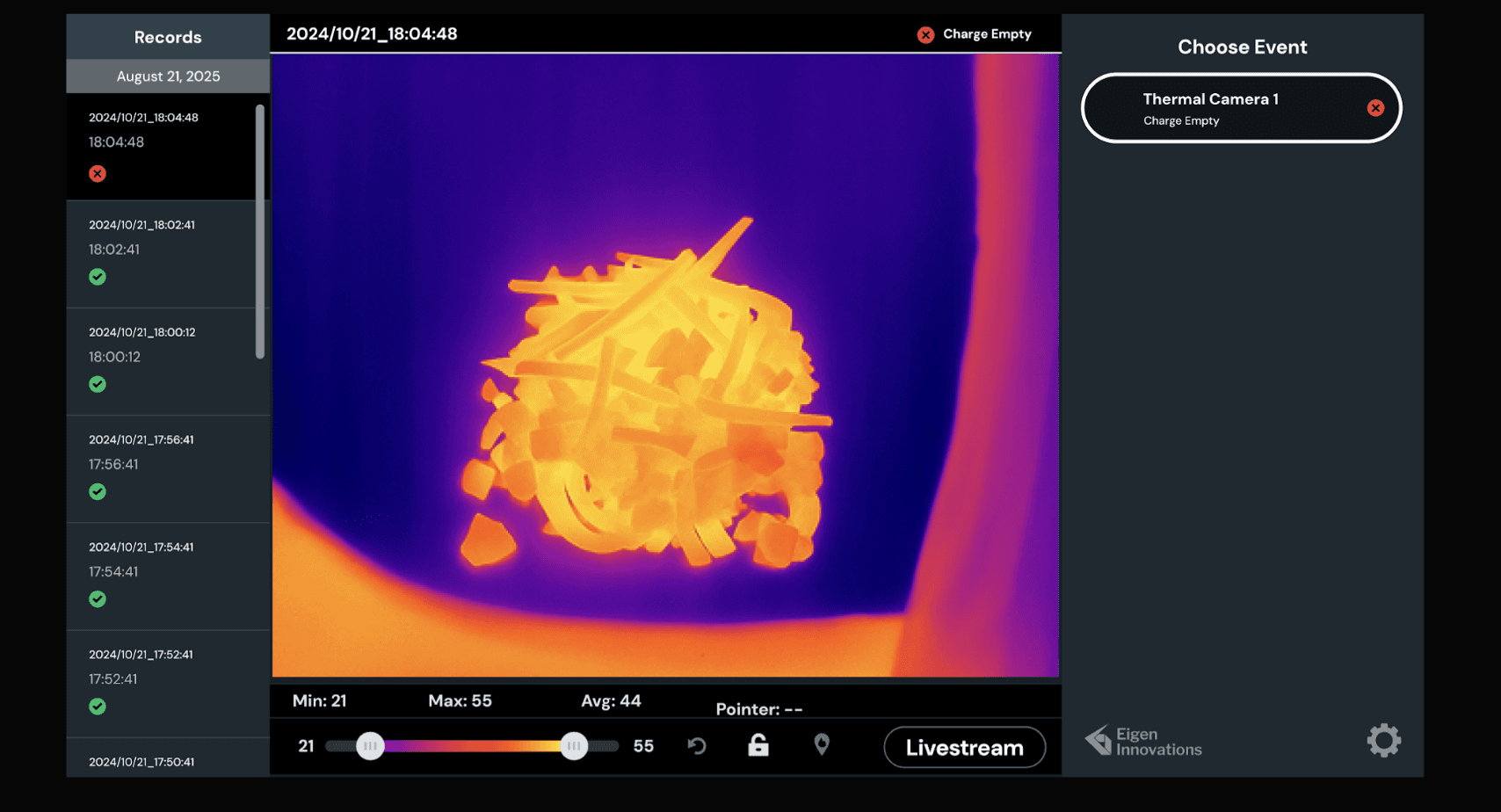

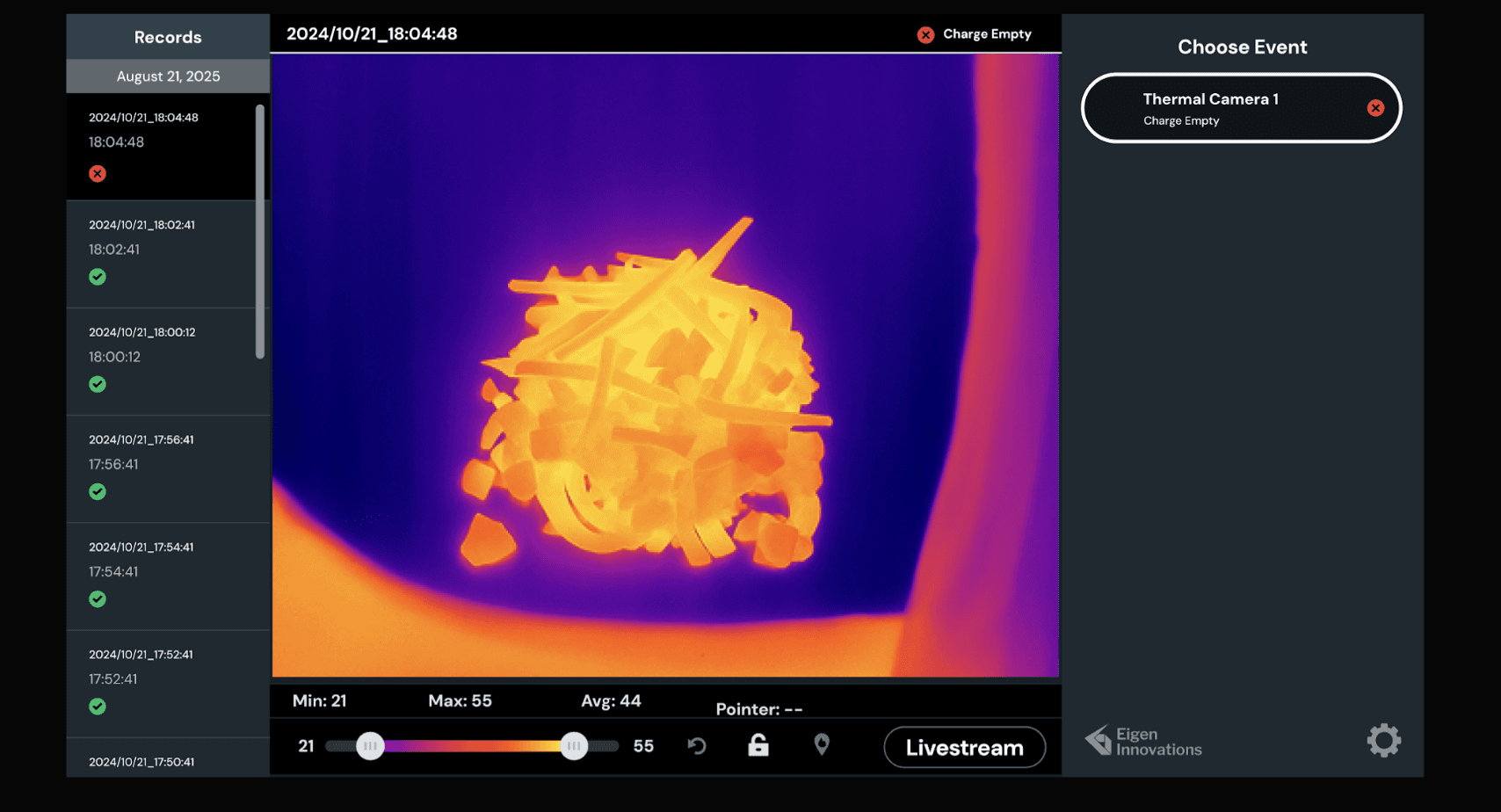

Eigen’s AI-powered cupola fill level monitoring solution analyzes the internal thermal profile of the furnace to estimate charge height and track how the burden rises and melts over time. By learning the temperature patterns associated with empty, full, and abnormal behavior, the system provides a real-time view of furnace conditions that are difficult to assess through manual observation alone.

A rugged thermal camera installed at the charge deck continuously captures thermal images of the charge zone. OneView applies trained algorithms to interpret thermal gradients and determine when the charge height is approaching the refill threshold or when the burden is rising unevenly. Operators receive instant alerts through the HMI, enabling timely charging, preventing cycle interruptions, and maintaining consistent furnace operation.

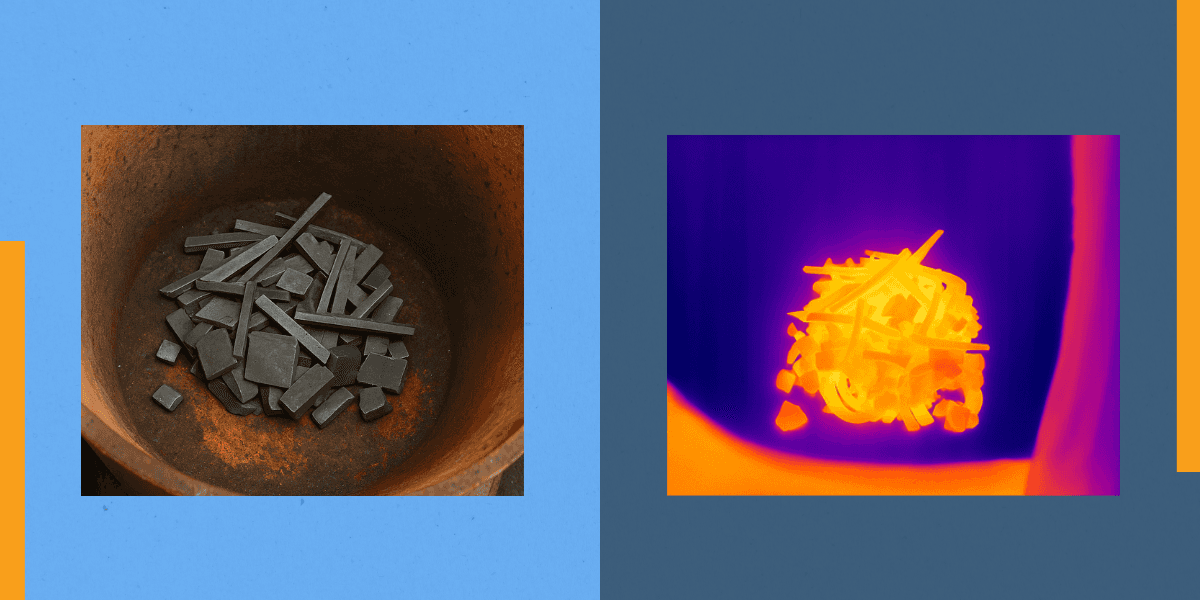

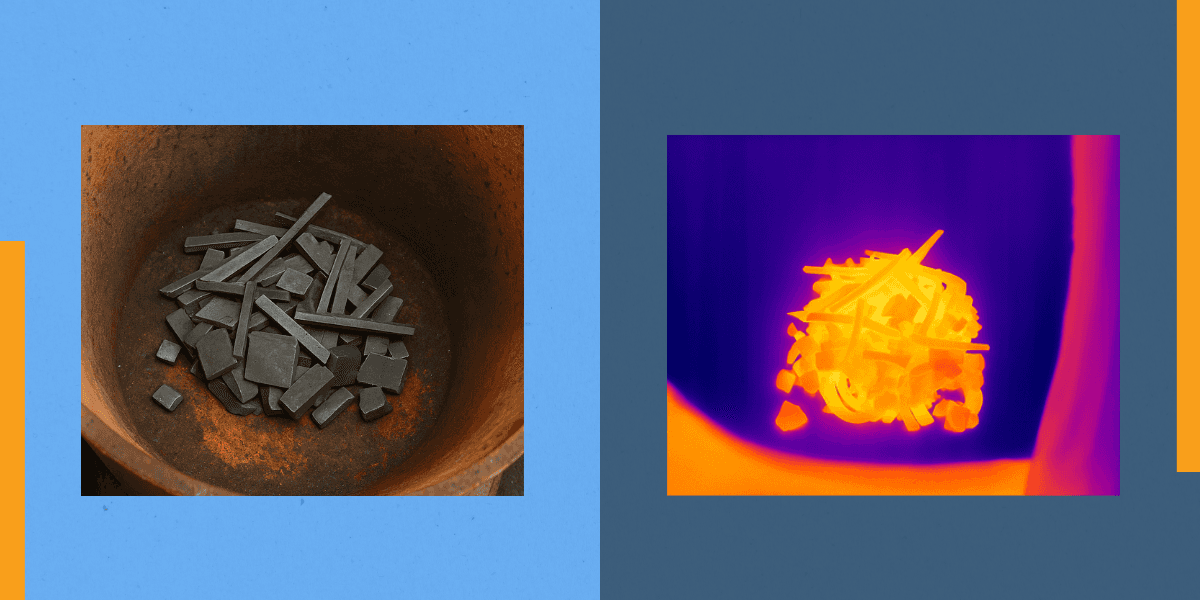

Operator view vs Eigen view

A side-by-side view demonstrating how thermal imaging exposes furnace conditions and charge behavior that operators cannot reliably see with manual checks.

Benefits

Consistent Charging Cycles: Alerts operators when charge height approaches refill thresholds to support stable feed rates and furnace performance.

Early Detection of Bridging and Hang-Ups: Identifies thermal patterns associated with stalled descent, uneven charging, or irregular melt behavior before disruptions occur.

Real-Time Charge Level Estimation: Classifies charge bed state as Empty or Full based on thermal gradients, reducing reliance on manual observation.

Improved Furnace Stability: Tracks how solid charge transitions during melt, helping operators catch irregular rise and heating behavior early.

Instant Notifications and Live Monitoring: Provides HMI alerts at the charge deck and enables operators to review a live camera stream for rapid validation.

Traceability and Continuous Improvement: Logs charge events in OneView for analysis, training, and improving predictive accuracy over time.

The Challenge

In cupola furnace operations, maintaining the correct charge height is critical for stable melting and consistent iron output. Abnormal behavior in how the charge bed rises, settles, or heats can signal issues such as bridging, hang-ups, uneven charging, or irregular melt rates.

If these conditions go undetected, they can lead to melt-quality variation, reduced energy efficiency, and unplanned disruptions to charging cycles. By ensuring the charge level does not drop below the desired threshold, operators can maintain consistent feed rates and keep cupola performance stable and efficient.

Our Solution

Eigen’s AI-powered cupola fill level monitoring solution analyzes the internal thermal profile of the furnace to estimate charge height and track how the burden rises and melts over time. By learning the temperature patterns associated with empty, full, and abnormal behavior, the system provides a real-time view of furnace conditions that are difficult to assess through manual observation alone.

A rugged thermal camera installed at the charge deck continuously captures thermal images of the charge zone. OneView applies trained algorithms to interpret thermal gradients and determine when the charge height is approaching the refill threshold or when the burden is rising unevenly. Operators receive instant alerts through the HMI, enabling timely charging, preventing cycle interruptions, and maintaining consistent furnace operation.

Operator view vs Eigen view

A side-by-side view demonstrating how thermal imaging exposes furnace conditions and charge behavior that operators cannot reliably see with manual checks.

Benefits

Consistent Charging Cycles: Alerts operators when charge height approaches refill thresholds to support stable feed rates and furnace performance.

Early Detection of Bridging and Hang-Ups: Identifies thermal patterns associated with stalled descent, uneven charging, or irregular melt behavior before disruptions occur.

Real-Time Charge Level Estimation: Classifies charge bed state as Empty or Full based on thermal gradients, reducing reliance on manual observation.

Improved Furnace Stability: Tracks how solid charge transitions during melt, helping operators catch irregular rise and heating behavior early.

Instant Notifications and Live Monitoring: Provides HMI alerts at the charge deck and enables operators to review a live camera stream for rapid validation.

Traceability and Continuous Improvement: Logs charge events in OneView for analysis, training, and improving predictive accuracy over time.

The Challenge

In cupola furnace operations, maintaining the correct charge height is critical for stable melting and consistent iron output. Abnormal behavior in how the charge bed rises, settles, or heats can signal issues such as bridging, hang-ups, uneven charging, or irregular melt rates.

If these conditions go undetected, they can lead to melt-quality variation, reduced energy efficiency, and unplanned disruptions to charging cycles. By ensuring the charge level does not drop below the desired threshold, operators can maintain consistent feed rates and keep cupola performance stable and efficient.

Our Solution

Eigen’s AI-powered cupola fill level monitoring solution analyzes the internal thermal profile of the furnace to estimate charge height and track how the burden rises and melts over time. By learning the temperature patterns associated with empty, full, and abnormal behavior, the system provides a real-time view of furnace conditions that are difficult to assess through manual observation alone.

A rugged thermal camera installed at the charge deck continuously captures thermal images of the charge zone. OneView applies trained algorithms to interpret thermal gradients and determine when the charge height is approaching the refill threshold or when the burden is rising unevenly. Operators receive instant alerts through the HMI, enabling timely charging, preventing cycle interruptions, and maintaining consistent furnace operation.

Operator view vs Eigen view

A side-by-side view demonstrating how thermal imaging exposes furnace conditions and charge behavior that operators cannot reliably see with manual checks.

Benefits

Consistent Charging Cycles: Alerts operators when charge height approaches refill thresholds to support stable feed rates and furnace performance.

Early Detection of Bridging and Hang-Ups: Identifies thermal patterns associated with stalled descent, uneven charging, or irregular melt behavior before disruptions occur.

Real-Time Charge Level Estimation: Classifies charge bed state as Empty or Full based on thermal gradients, reducing reliance on manual observation.

Improved Furnace Stability: Tracks how solid charge transitions during melt, helping operators catch irregular rise and heating behavior early.

Instant Notifications and Live Monitoring: Provides HMI alerts at the charge deck and enables operators to review a live camera stream for rapid validation.

Traceability and Continuous Improvement: Logs charge events in OneView for analysis, training, and improving predictive accuracy over time.

The Challenge

In cupola furnace operations, maintaining the correct charge height is critical for stable melting and consistent iron output. Abnormal behavior in how the charge bed rises, settles, or heats can signal issues such as bridging, hang-ups, uneven charging, or irregular melt rates.

If these conditions go undetected, they can lead to melt-quality variation, reduced energy efficiency, and unplanned disruptions to charging cycles. By ensuring the charge level does not drop below the desired threshold, operators can maintain consistent feed rates and keep cupola performance stable and efficient.

Our Solution

Eigen’s AI-powered cupola fill level monitoring solution analyzes the internal thermal profile of the furnace to estimate charge height and track how the burden rises and melts over time. By learning the temperature patterns associated with empty, full, and abnormal behavior, the system provides a real-time view of furnace conditions that are difficult to assess through manual observation alone.

A rugged thermal camera installed at the charge deck continuously captures thermal images of the charge zone. OneView applies trained algorithms to interpret thermal gradients and determine when the charge height is approaching the refill threshold or when the burden is rising unevenly. Operators receive instant alerts through the HMI, enabling timely charging, preventing cycle interruptions, and maintaining consistent furnace operation.

Operator view vs Eigen view

A side-by-side view demonstrating how thermal imaging exposes furnace conditions and charge behavior that operators cannot reliably see with manual checks.

Benefits

Consistent Charging Cycles: Alerts operators when charge height approaches refill thresholds to support stable feed rates and furnace performance.

Early Detection of Bridging and Hang-Ups: Identifies thermal patterns associated with stalled descent, uneven charging, or irregular melt behavior before disruptions occur.

Real-Time Charge Level Estimation: Classifies charge bed state as Empty or Full based on thermal gradients, reducing reliance on manual observation.

Improved Furnace Stability: Tracks how solid charge transitions during melt, helping operators catch irregular rise and heating behavior early.

Instant Notifications and Live Monitoring: Provides HMI alerts at the charge deck and enables operators to review a live camera stream for rapid validation.

Traceability and Continuous Improvement: Logs charge events in OneView for analysis, training, and improving predictive accuracy over time.

Read more

Fill Level Monitoring

Metals

Real-time thermal monitoring system that estimates charge height and alerts operators before refill thresholds are missed, improving melt stability and reducing charging disruptions.

Download

Sheet

Solution

Fill Level Monitoring