Metals

Flow Monitoring

Real-time thermal monitoring system that verifies molten iron flow presence, stability, and temperature to prevent casting defects, downtime, and safety risks.

The Challenge

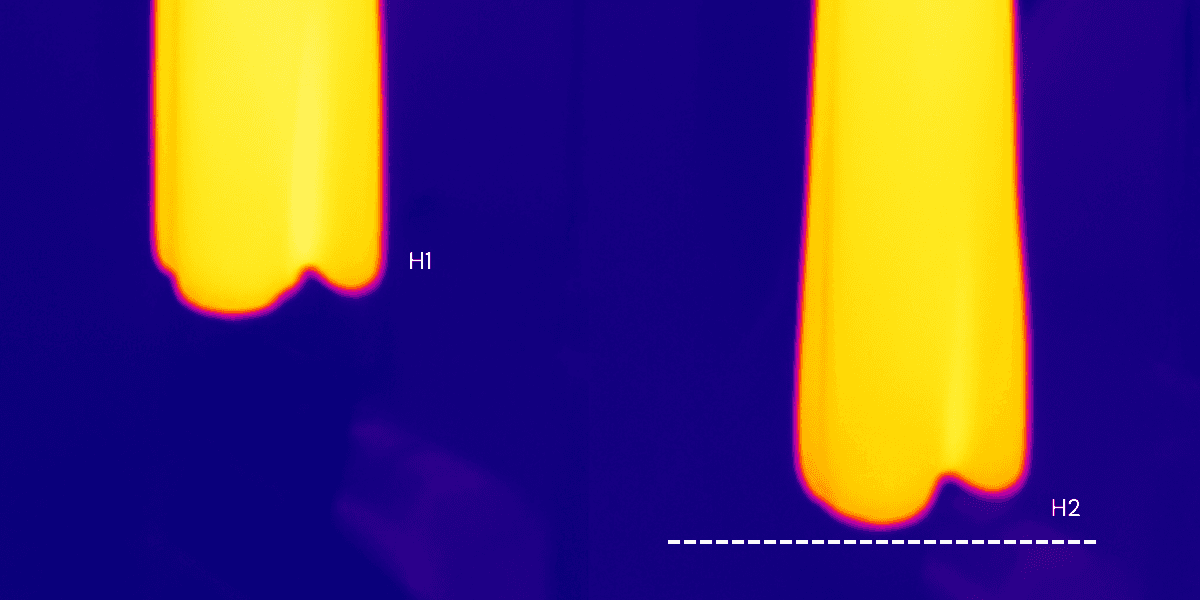

In foundry and melt-handling operations, maintaining a stable, continuous, and properly heated molten iron stream is essential for safe and consistent casting. Variations in thermal profile, flow presence, or stream behavior can signal early-stage issues such as cooling, channel buildup, bridging, partial blockages, or interruptions in the tap or trough.

When these conditions go undetected, they often result in casting defects, unstable pour temperatures, downstream equipment fouling, unplanned stoppages, and increased operator safety risks. As production environments become more demanding, the need for reliable, real-time visibility into molten flow behavior becomes critical.

Our Solution

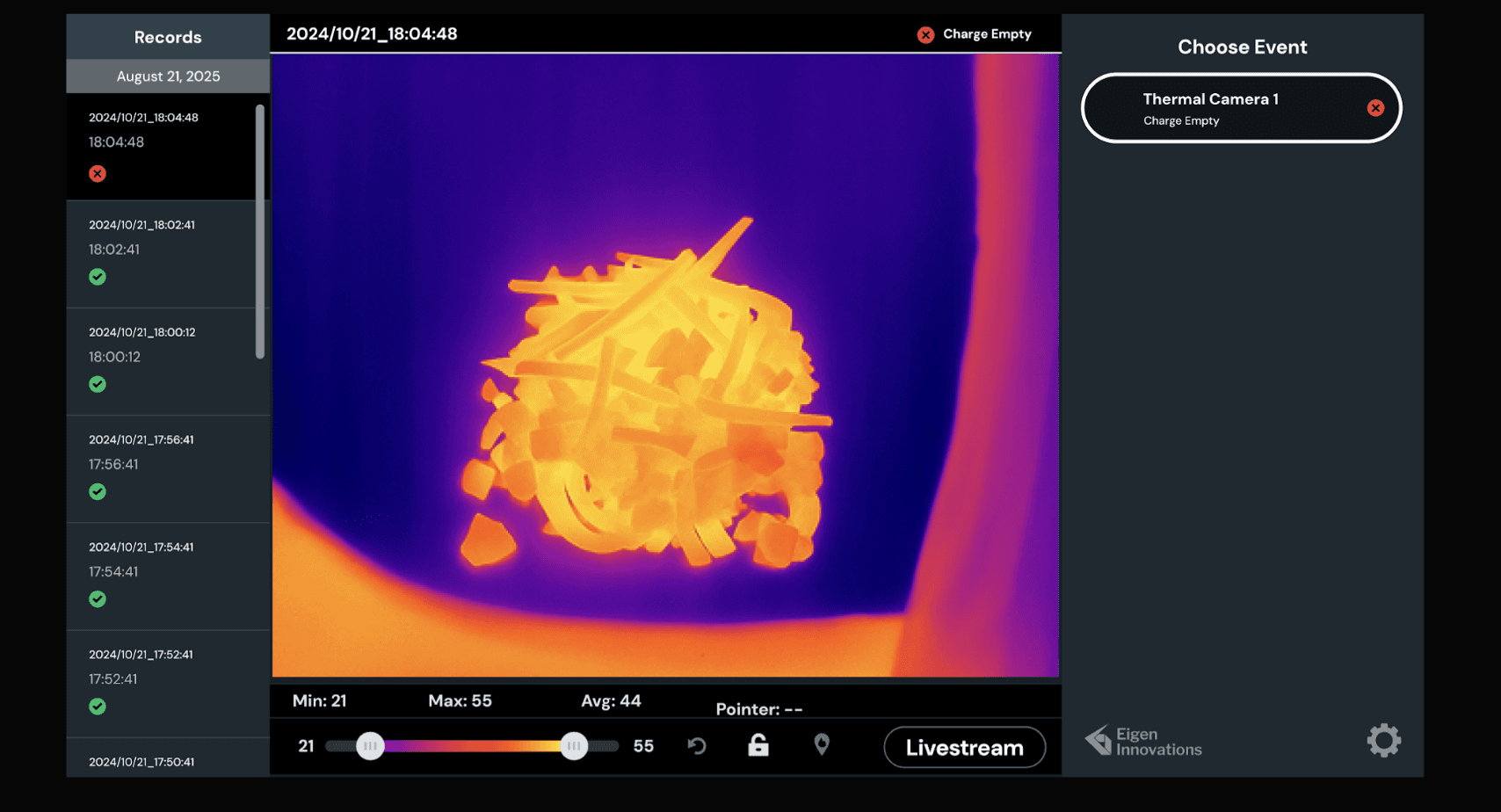

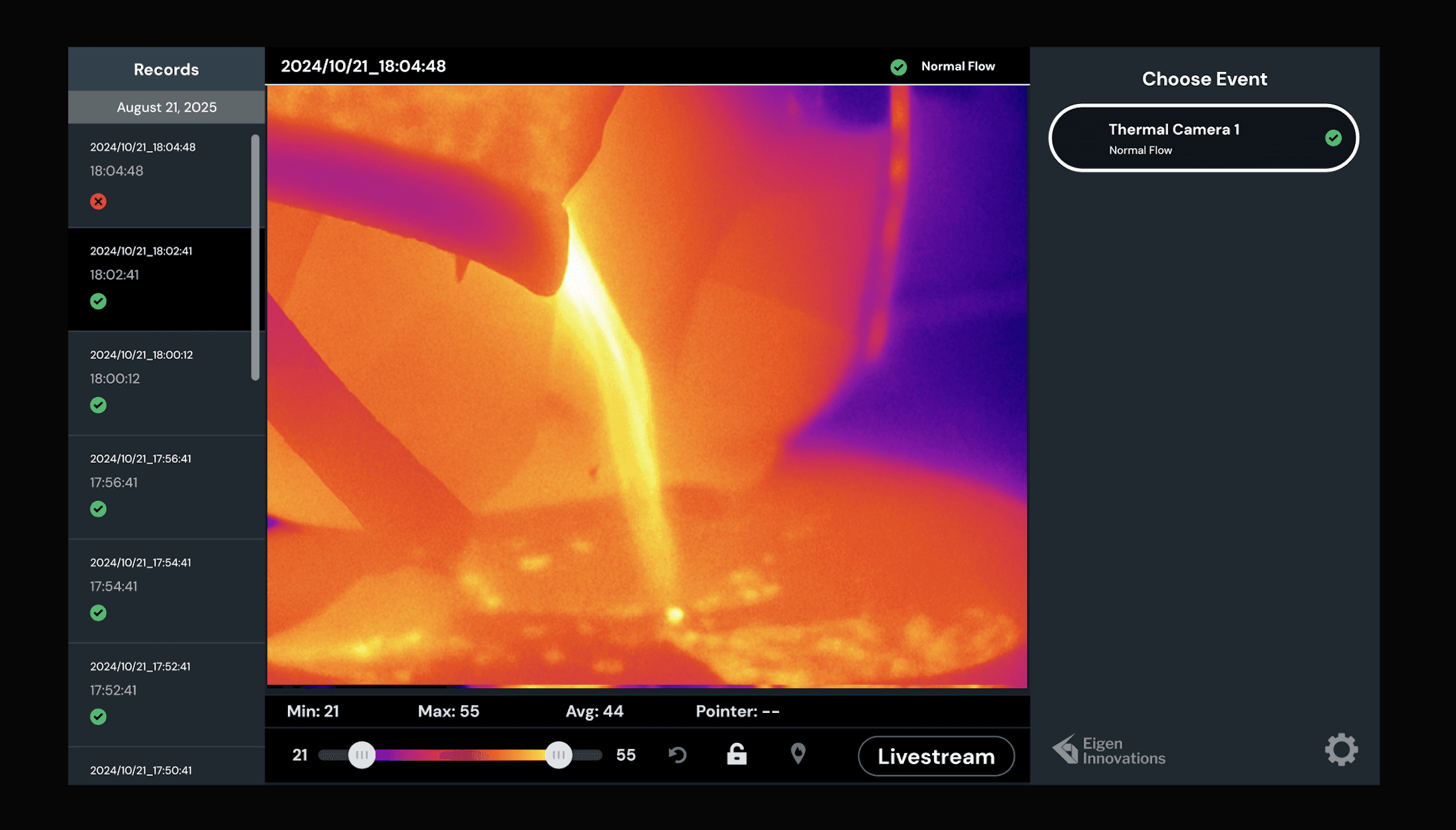

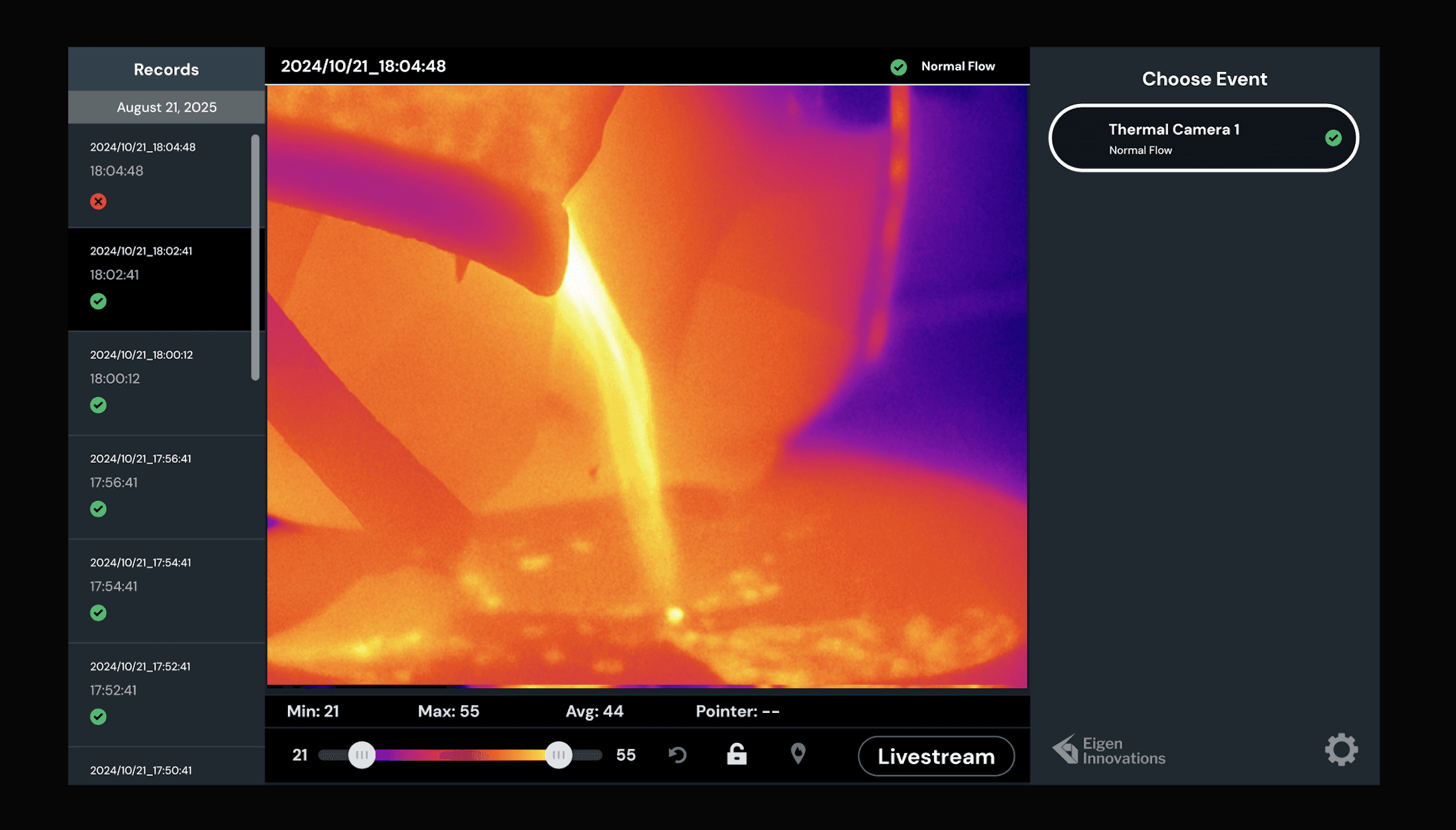

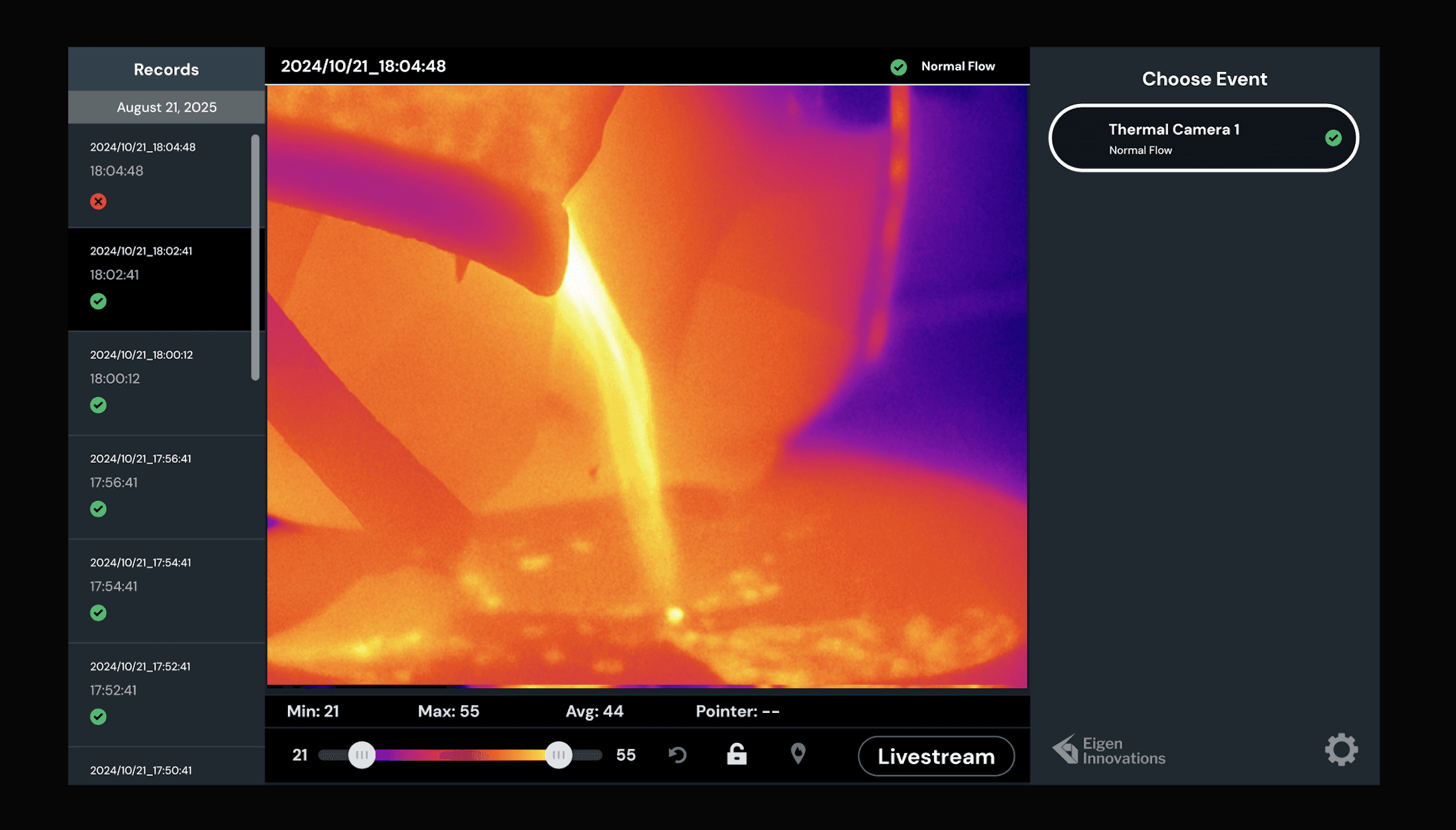

Eigen’s AI-powered molten iron flow monitoring solution continuously analyzes live thermal images of the molten stream to verify flow presence, stability, and temperature in real time. By identifying subtle deviations in thermal behavior and flow continuity, the system alerts operators early, enabling corrective action before issues escalate into defects or downtime.

A fixed, ruggedized thermal camera monitors the tap or trough continuously. Each thermal frame is processed in OneView using machine learning models trained specifically on molten metal behavior. The system classifies flow conditions and detects abnormal cooling, thinning, or interruptions that may indicate developing blockages or upstream instability.

Operators receive immediate alerts through the HMI and light stack at the melt station, allowing rapid intervention and improved process control. All detected events are recorded in OneView for traceability, review, and continuous process improvement.

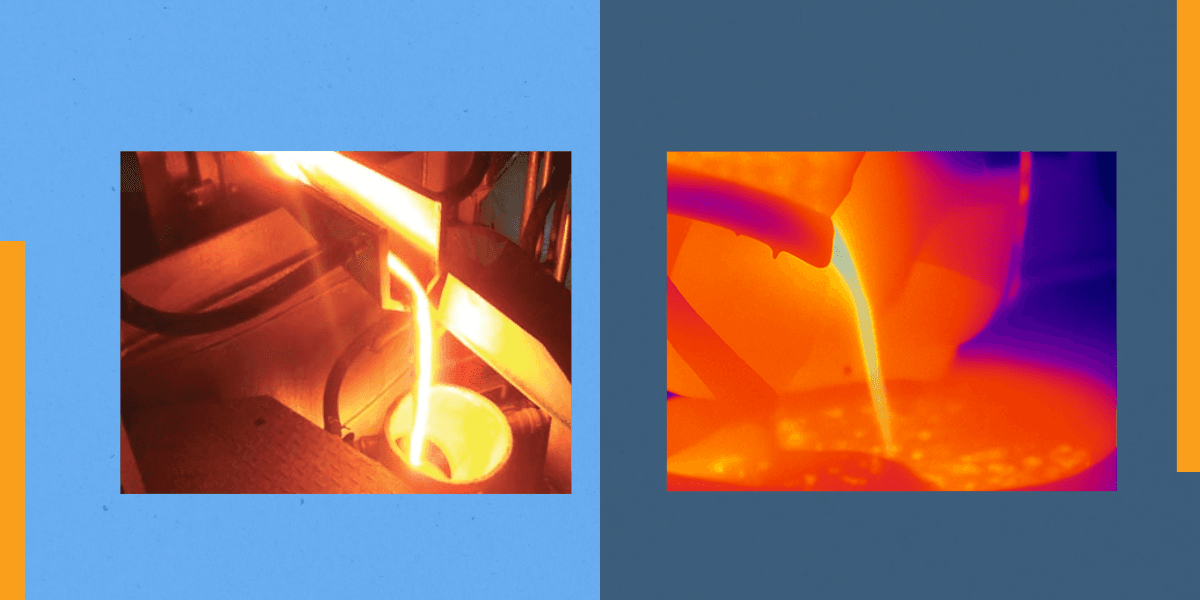

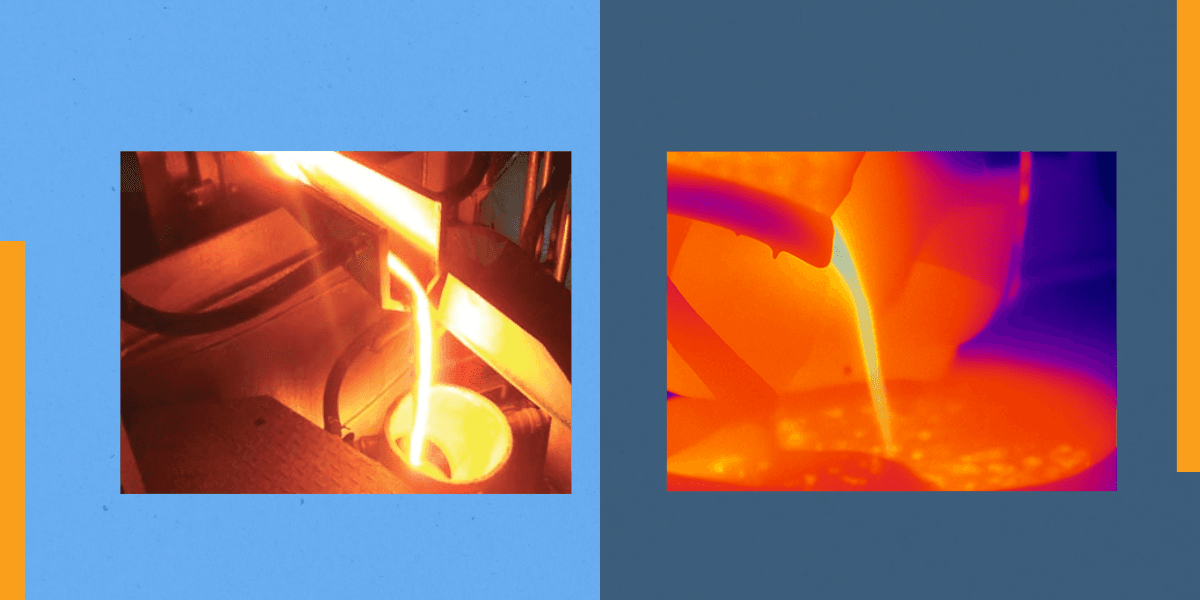

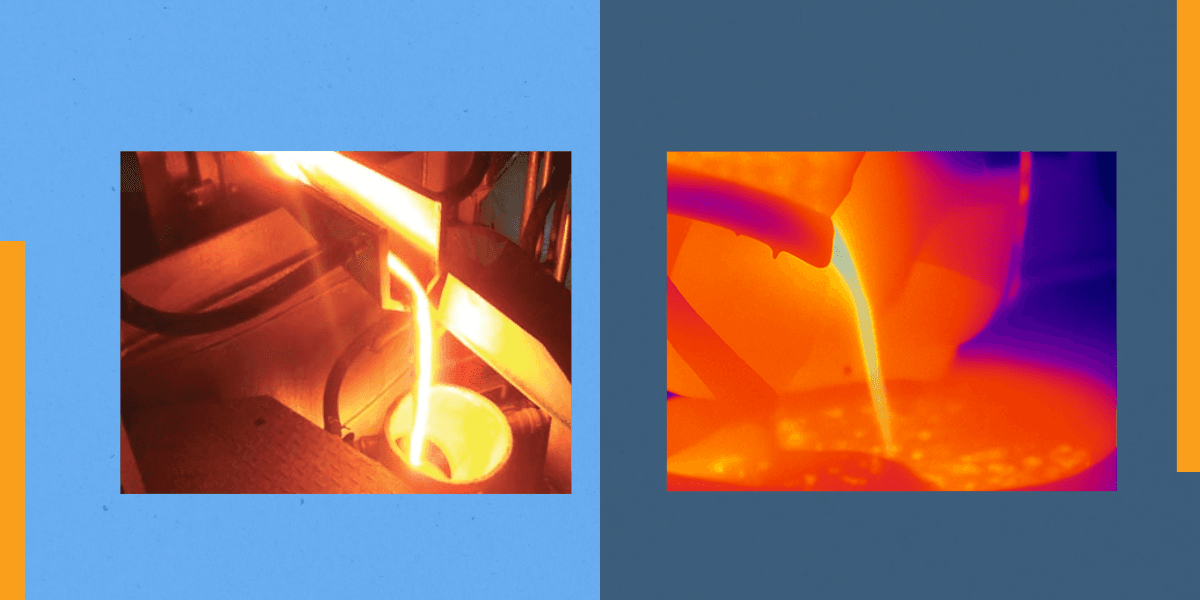

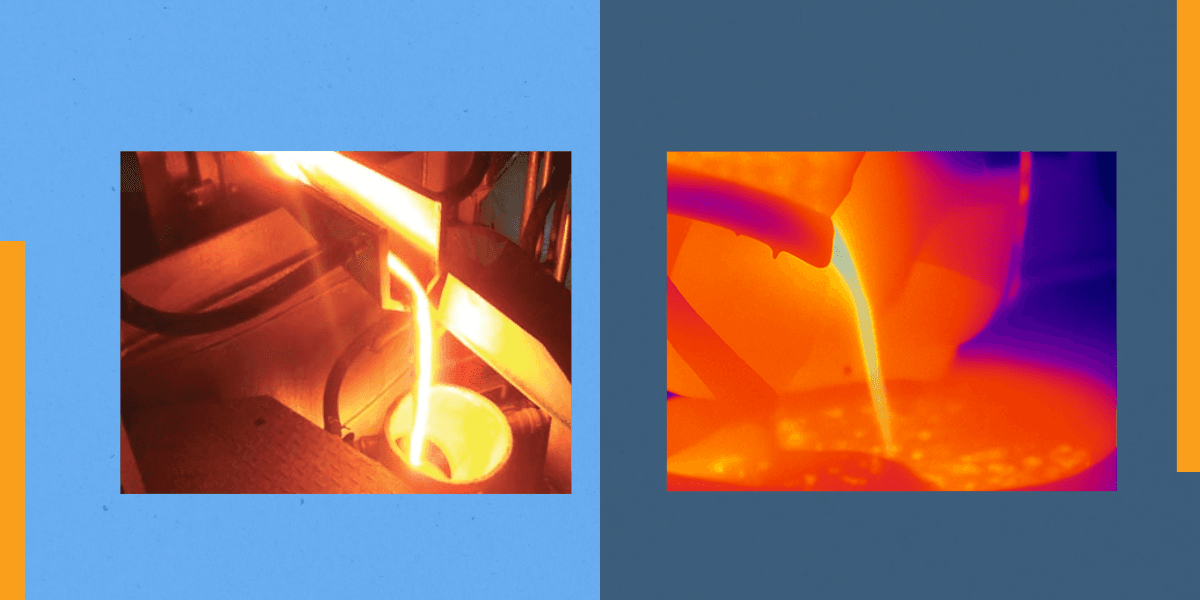

Operator view vs Eigen view

A side-by-side comparison showing how thermal imaging and AI reveal molten flow behavior, cooling patterns, and interruptions that are not visible to the human eye.

Benefits

Improved Casting Stability: Continuously verifies molten flow presence and temperature to support consistent pours and reduce casting defects.

Early Issue Detection: Identifies cooling, thinning, and flow interruptions before they escalate into blockages or unplanned downtime.

Clear Flow State Diagnosis: Classifies flow conditions as Normal, Abnormal, or Fault, giving operators an immediate and consistent understanding of process health.

Real-Time Operator Alerts: Instant notifications through HMI and light stacks enable faster response and safer operations at the melt station.

Traceability and Root-Cause Analysis: Thermal events are stored in OneView for review, training, and validation of corrective actions.

Rugged and Scalable: Designed for harsh foundry environments and adaptable to different melt stations, tap designs, and operating conditions without manual reconfiguration.

The Challenge

In foundry and melt-handling operations, maintaining a stable, continuous, and properly heated molten iron stream is essential for safe and consistent casting. Variations in thermal profile, flow presence, or stream behavior can signal early-stage issues such as cooling, channel buildup, bridging, partial blockages, or interruptions in the tap or trough.

When these conditions go undetected, they often result in casting defects, unstable pour temperatures, downstream equipment fouling, unplanned stoppages, and increased operator safety risks. As production environments become more demanding, the need for reliable, real-time visibility into molten flow behavior becomes critical.

Our Solution

Eigen’s AI-powered molten iron flow monitoring solution continuously analyzes live thermal images of the molten stream to verify flow presence, stability, and temperature in real time. By identifying subtle deviations in thermal behavior and flow continuity, the system alerts operators early, enabling corrective action before issues escalate into defects or downtime.

A fixed, ruggedized thermal camera monitors the tap or trough continuously. Each thermal frame is processed in OneView using machine learning models trained specifically on molten metal behavior. The system classifies flow conditions and detects abnormal cooling, thinning, or interruptions that may indicate developing blockages or upstream instability.

Operators receive immediate alerts through the HMI and light stack at the melt station, allowing rapid intervention and improved process control. All detected events are recorded in OneView for traceability, review, and continuous process improvement.

Operator view vs Eigen view

A side-by-side comparison showing how thermal imaging and AI reveal molten flow behavior, cooling patterns, and interruptions that are not visible to the human eye.

Benefits

Improved Casting Stability: Continuously verifies molten flow presence and temperature to support consistent pours and reduce casting defects.

Early Issue Detection: Identifies cooling, thinning, and flow interruptions before they escalate into blockages or unplanned downtime.

Clear Flow State Diagnosis: Classifies flow conditions as Normal, Abnormal, or Fault, giving operators an immediate and consistent understanding of process health.

Real-Time Operator Alerts: Instant notifications through HMI and light stacks enable faster response and safer operations at the melt station.

Traceability and Root-Cause Analysis: Thermal events are stored in OneView for review, training, and validation of corrective actions.

Rugged and Scalable: Designed for harsh foundry environments and adaptable to different melt stations, tap designs, and operating conditions without manual reconfiguration.

The Challenge

In foundry and melt-handling operations, maintaining a stable, continuous, and properly heated molten iron stream is essential for safe and consistent casting. Variations in thermal profile, flow presence, or stream behavior can signal early-stage issues such as cooling, channel buildup, bridging, partial blockages, or interruptions in the tap or trough.

When these conditions go undetected, they often result in casting defects, unstable pour temperatures, downstream equipment fouling, unplanned stoppages, and increased operator safety risks. As production environments become more demanding, the need for reliable, real-time visibility into molten flow behavior becomes critical.

Our Solution

Eigen’s AI-powered molten iron flow monitoring solution continuously analyzes live thermal images of the molten stream to verify flow presence, stability, and temperature in real time. By identifying subtle deviations in thermal behavior and flow continuity, the system alerts operators early, enabling corrective action before issues escalate into defects or downtime.

A fixed, ruggedized thermal camera monitors the tap or trough continuously. Each thermal frame is processed in OneView using machine learning models trained specifically on molten metal behavior. The system classifies flow conditions and detects abnormal cooling, thinning, or interruptions that may indicate developing blockages or upstream instability.

Operators receive immediate alerts through the HMI and light stack at the melt station, allowing rapid intervention and improved process control. All detected events are recorded in OneView for traceability, review, and continuous process improvement.

Operator view vs Eigen view

A side-by-side comparison showing how thermal imaging and AI reveal molten flow behavior, cooling patterns, and interruptions that are not visible to the human eye.

Benefits

Improved Casting Stability: Continuously verifies molten flow presence and temperature to support consistent pours and reduce casting defects.

Early Issue Detection: Identifies cooling, thinning, and flow interruptions before they escalate into blockages or unplanned downtime.

Clear Flow State Diagnosis: Classifies flow conditions as Normal, Abnormal, or Fault, giving operators an immediate and consistent understanding of process health.

Real-Time Operator Alerts: Instant notifications through HMI and light stacks enable faster response and safer operations at the melt station.

Traceability and Root-Cause Analysis: Thermal events are stored in OneView for review, training, and validation of corrective actions.

Rugged and Scalable: Designed for harsh foundry environments and adaptable to different melt stations, tap designs, and operating conditions without manual reconfiguration.

The Challenge

In foundry and melt-handling operations, maintaining a stable, continuous, and properly heated molten iron stream is essential for safe and consistent casting. Variations in thermal profile, flow presence, or stream behavior can signal early-stage issues such as cooling, channel buildup, bridging, partial blockages, or interruptions in the tap or trough.

When these conditions go undetected, they often result in casting defects, unstable pour temperatures, downstream equipment fouling, unplanned stoppages, and increased operator safety risks. As production environments become more demanding, the need for reliable, real-time visibility into molten flow behavior becomes critical.

Our Solution

Eigen’s AI-powered molten iron flow monitoring solution continuously analyzes live thermal images of the molten stream to verify flow presence, stability, and temperature in real time. By identifying subtle deviations in thermal behavior and flow continuity, the system alerts operators early, enabling corrective action before issues escalate into defects or downtime.

A fixed, ruggedized thermal camera monitors the tap or trough continuously. Each thermal frame is processed in OneView using machine learning models trained specifically on molten metal behavior. The system classifies flow conditions and detects abnormal cooling, thinning, or interruptions that may indicate developing blockages or upstream instability.

Operators receive immediate alerts through the HMI and light stack at the melt station, allowing rapid intervention and improved process control. All detected events are recorded in OneView for traceability, review, and continuous process improvement.

Operator view vs Eigen view

A side-by-side comparison showing how thermal imaging and AI reveal molten flow behavior, cooling patterns, and interruptions that are not visible to the human eye.

Benefits

Improved Casting Stability: Continuously verifies molten flow presence and temperature to support consistent pours and reduce casting defects.

Early Issue Detection: Identifies cooling, thinning, and flow interruptions before they escalate into blockages or unplanned downtime.

Clear Flow State Diagnosis: Classifies flow conditions as Normal, Abnormal, or Fault, giving operators an immediate and consistent understanding of process health.

Real-Time Operator Alerts: Instant notifications through HMI and light stacks enable faster response and safer operations at the melt station.

Traceability and Root-Cause Analysis: Thermal events are stored in OneView for review, training, and validation of corrective actions.

Rugged and Scalable: Designed for harsh foundry environments and adaptable to different melt stations, tap designs, and operating conditions without manual reconfiguration.

Read more

Flow Monitoring

Metals

Real-time thermal monitoring system that verifies molten iron flow presence, stability, and temperature to prevent casting defects, downtime, and safety risks.

Download

Sheet

Solution

Flow Monitoring