Plastics

Blow Mold Parison Monitoring

Real-time AI thermal inspection that helps manufacturers detect parison issues early, reducing scrap, rework, and machine downtime.

The Challenge

In extrusion blow molding, molten plastic is extruded into a parison, inflated inside a mold, and cooled to form hollow parts. Variations in parison length, temperature, or alignment can lead to uneven wall thickness, flash, or incomplete fills.

These issues often arise from unstable melt temperature, poor die cut-off, mold set-up changes, or machine drift, causing material waste, part defects, and costly downtime.

Our Solution

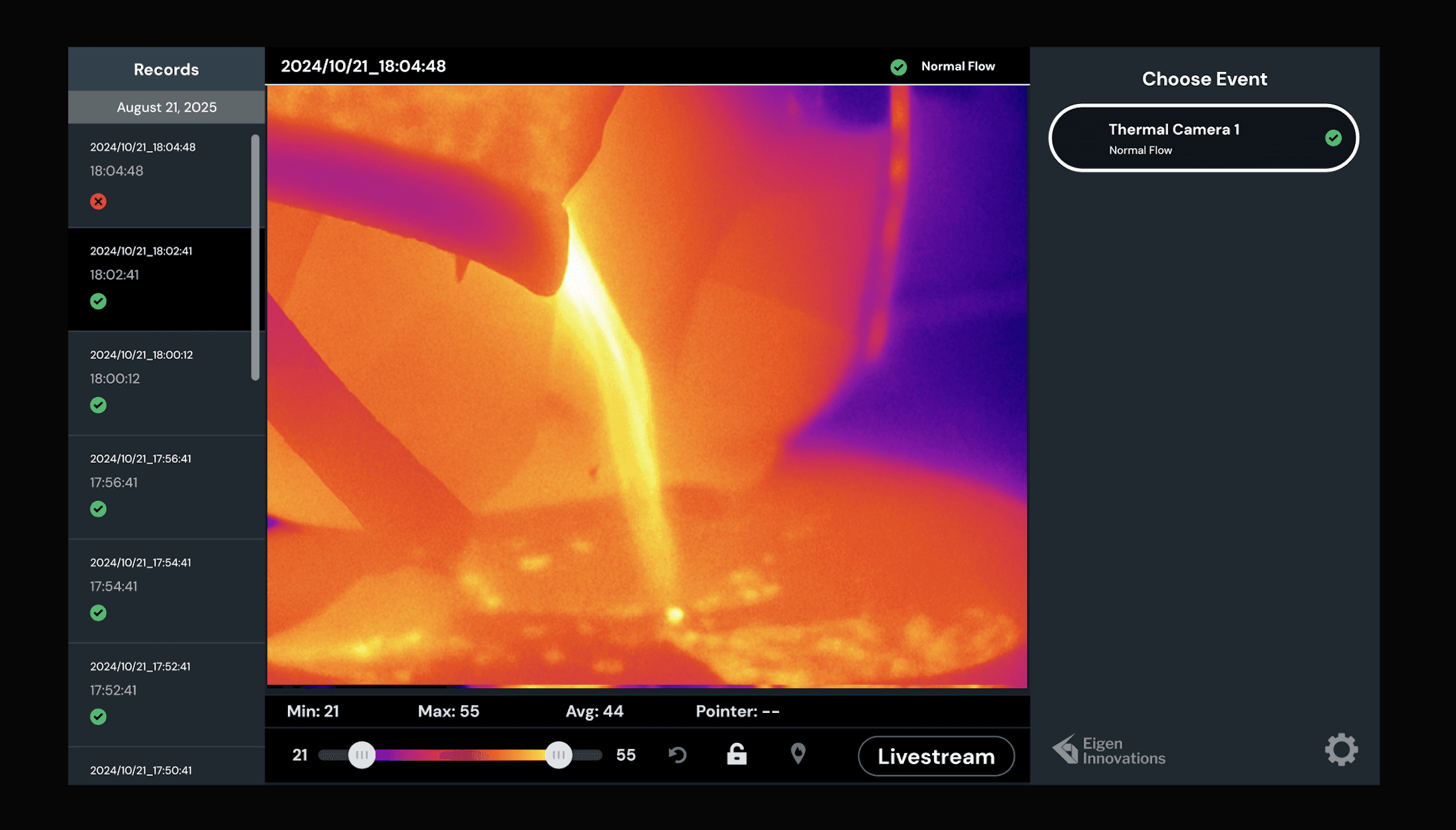

Eigen’s AI-powered thermal inspection system captures and analyzes thermal images of the parison as it forms to detect irregularities in shape, length, and temperature distribution.

Multiple thermal cameras provide a full view of the parison, with images triggered either at the end of formation or continuously as it extrudes. Within OneView, trained AI models analyze these images for shape and temperature uniformity, alerting operators to deviations in real time.

This visibility is especially valuable during mold changes, ensuring good parts are produced from the very first cycle and helping teams maintain consistent process control across shifts.

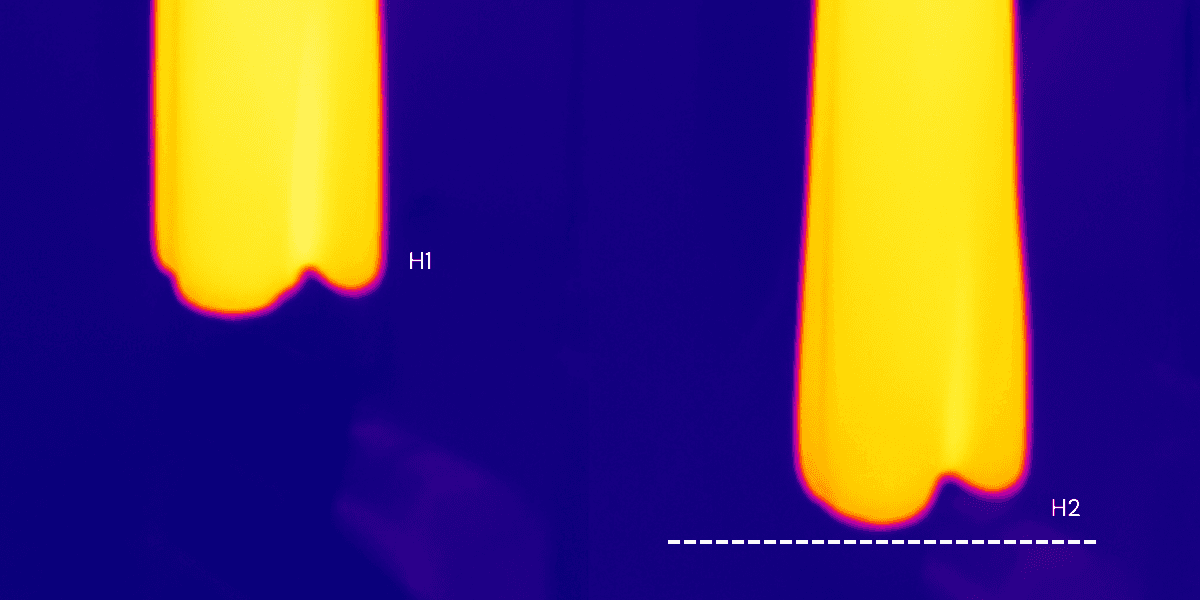

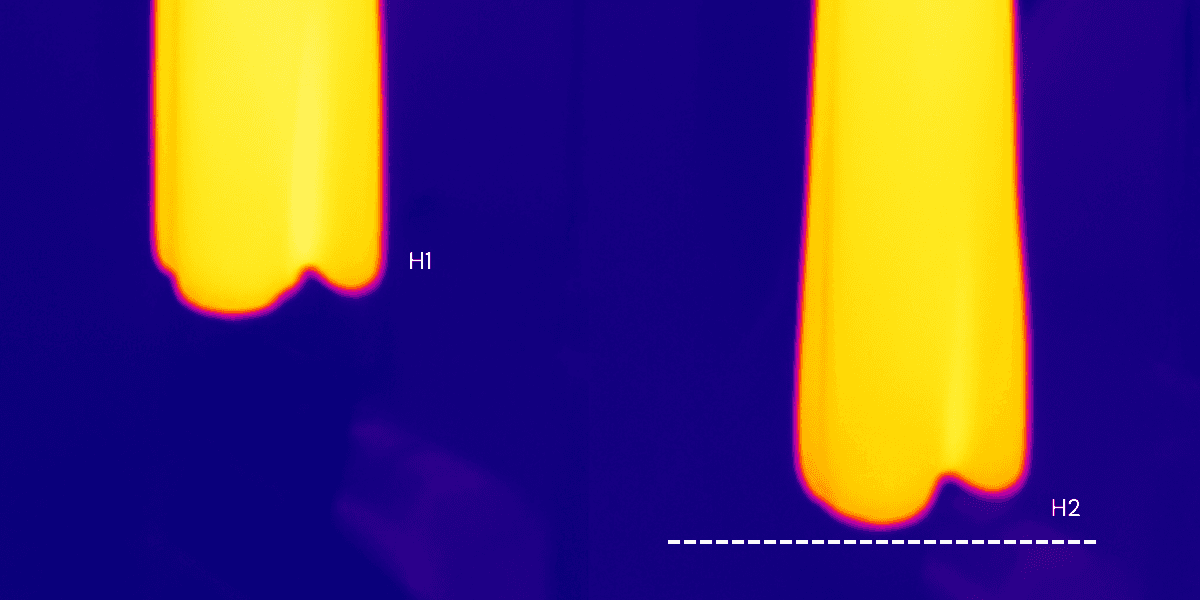

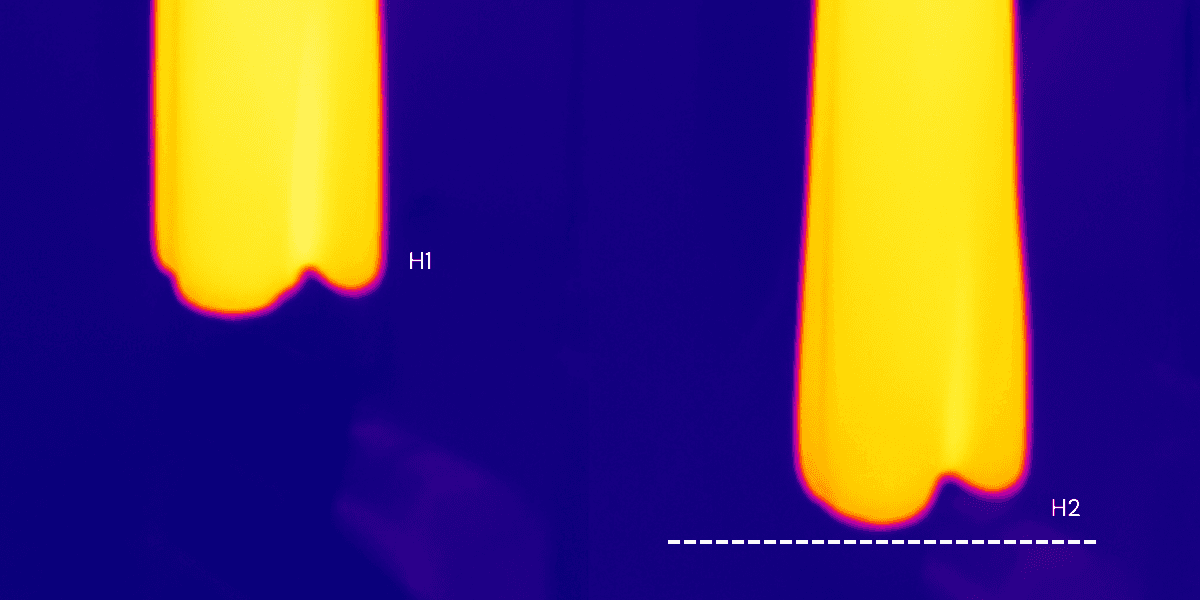

Operator view vs Eigen view

A look at how Eigen’s vision system reveals subtle parison variations invisible during manual inspection.

Benefits

Shape and Integrity Monitoring: Detects sagging, stretching, or deformation that can affect part geometry, an early indicator of alignment or setup issues.

Parison Length Tracking: Verifies consistency in parison length to prevent early cut-offs or mold mismatches.

Thermal Uniformity Monitoring: Tracks temperature gradients across the parison to spot cold zones, overheating, or uneven cooling before defects occur.

Die and Spill Detection: Identifies molten plastic overflow or buildup near the die head, signaling potential wear, sealing, or backpressure issues.

Reduced Scrap and Downtime: Real-time alerts help teams correct process drift early, minimizing waste and keeping production efficient.

The Challenge

In extrusion blow molding, molten plastic is extruded into a parison, inflated inside a mold, and cooled to form hollow parts. Variations in parison length, temperature, or alignment can lead to uneven wall thickness, flash, or incomplete fills.

These issues often arise from unstable melt temperature, poor die cut-off, mold set-up changes, or machine drift, causing material waste, part defects, and costly downtime.

Our Solution

Eigen’s AI-powered thermal inspection system captures and analyzes thermal images of the parison as it forms to detect irregularities in shape, length, and temperature distribution.

Multiple thermal cameras provide a full view of the parison, with images triggered either at the end of formation or continuously as it extrudes. Within OneView, trained AI models analyze these images for shape and temperature uniformity, alerting operators to deviations in real time.

This visibility is especially valuable during mold changes, ensuring good parts are produced from the very first cycle and helping teams maintain consistent process control across shifts.

Operator view vs Eigen view

A look at how Eigen’s vision system reveals subtle parison variations invisible during manual inspection.

Benefits

Shape and Integrity Monitoring: Detects sagging, stretching, or deformation that can affect part geometry, an early indicator of alignment or setup issues.

Parison Length Tracking: Verifies consistency in parison length to prevent early cut-offs or mold mismatches.

Thermal Uniformity Monitoring: Tracks temperature gradients across the parison to spot cold zones, overheating, or uneven cooling before defects occur.

Die and Spill Detection: Identifies molten plastic overflow or buildup near the die head, signaling potential wear, sealing, or backpressure issues.

Reduced Scrap and Downtime: Real-time alerts help teams correct process drift early, minimizing waste and keeping production efficient.

The Challenge

In extrusion blow molding, molten plastic is extruded into a parison, inflated inside a mold, and cooled to form hollow parts. Variations in parison length, temperature, or alignment can lead to uneven wall thickness, flash, or incomplete fills.

These issues often arise from unstable melt temperature, poor die cut-off, mold set-up changes, or machine drift, causing material waste, part defects, and costly downtime.

Our Solution

Eigen’s AI-powered thermal inspection system captures and analyzes thermal images of the parison as it forms to detect irregularities in shape, length, and temperature distribution.

Multiple thermal cameras provide a full view of the parison, with images triggered either at the end of formation or continuously as it extrudes. Within OneView, trained AI models analyze these images for shape and temperature uniformity, alerting operators to deviations in real time.

This visibility is especially valuable during mold changes, ensuring good parts are produced from the very first cycle and helping teams maintain consistent process control across shifts.

Operator view vs Eigen view

A look at how Eigen’s vision system reveals subtle parison variations invisible during manual inspection.

Benefits

Shape and Integrity Monitoring: Detects sagging, stretching, or deformation that can affect part geometry, an early indicator of alignment or setup issues.

Parison Length Tracking: Verifies consistency in parison length to prevent early cut-offs or mold mismatches.

Thermal Uniformity Monitoring: Tracks temperature gradients across the parison to spot cold zones, overheating, or uneven cooling before defects occur.

Die and Spill Detection: Identifies molten plastic overflow or buildup near the die head, signaling potential wear, sealing, or backpressure issues.

Reduced Scrap and Downtime: Real-time alerts help teams correct process drift early, minimizing waste and keeping production efficient.

The Challenge

In extrusion blow molding, molten plastic is extruded into a parison, inflated inside a mold, and cooled to form hollow parts. Variations in parison length, temperature, or alignment can lead to uneven wall thickness, flash, or incomplete fills.

These issues often arise from unstable melt temperature, poor die cut-off, mold set-up changes, or machine drift, causing material waste, part defects, and costly downtime.

Our Solution

Eigen’s AI-powered thermal inspection system captures and analyzes thermal images of the parison as it forms to detect irregularities in shape, length, and temperature distribution.

Multiple thermal cameras provide a full view of the parison, with images triggered either at the end of formation or continuously as it extrudes. Within OneView, trained AI models analyze these images for shape and temperature uniformity, alerting operators to deviations in real time.

This visibility is especially valuable during mold changes, ensuring good parts are produced from the very first cycle and helping teams maintain consistent process control across shifts.

Operator view vs Eigen view

A look at how Eigen’s vision system reveals subtle parison variations invisible during manual inspection.

Benefits

Shape and Integrity Monitoring: Detects sagging, stretching, or deformation that can affect part geometry, an early indicator of alignment or setup issues.

Parison Length Tracking: Verifies consistency in parison length to prevent early cut-offs or mold mismatches.

Thermal Uniformity Monitoring: Tracks temperature gradients across the parison to spot cold zones, overheating, or uneven cooling before defects occur.

Die and Spill Detection: Identifies molten plastic overflow or buildup near the die head, signaling potential wear, sealing, or backpressure issues.

Reduced Scrap and Downtime: Real-time alerts help teams correct process drift early, minimizing waste and keeping production efficient.

Read more

Blow Mold Parison Monitoring

Plastics

Real-time AI thermal inspection that helps manufacturers detect parison issues early, reducing scrap, rework, and machine downtime.

Download

Sheet

Solution

Blow Mold Parison Monitoring