Plastics

Hot Plate Weld Verification

Real-time thermal inspection system that identifies weld defects as they form, ensuring stronger bonds and consistent product quality.

The Challenge

In hot plate plastic welding, defects like incomplete fusion, misalignment, overheating, or weak bonds can occur due to warped geometry, uneven contact, or inconsistent heating. Traditional inspection methods rely on post-process sampling, which makes it difficult to catch defects in real time.These undetected issues can lead to part failures, costly rework, and warranty claims. As production speed and complexity increase, manufacturers need a faster, more reliable way to ensure every weld meets specification.

Our Solution

Eigen’s AI-powered thermal inspection system detects and classifies weld quality issues in-line, directly during the welding stage.Thermal cameras track temperature distribution, flatness, and fusion patterns across the weld perimeter, while AI models identify anomalies that signal weak or incomplete bonds.

Inspection data is processed in OneView Cloud, where operators can view severity scores, defect locations, and trend data for root-cause analysis. The system connects with the line’s PLC to trigger alarms or light stacks, allowing for immediate corrective action without halting production.

With configurable, customer-defined quality thresholds, engineers can fine-tune process parameters in real time and continuously improve weld consistency across multiple lines.

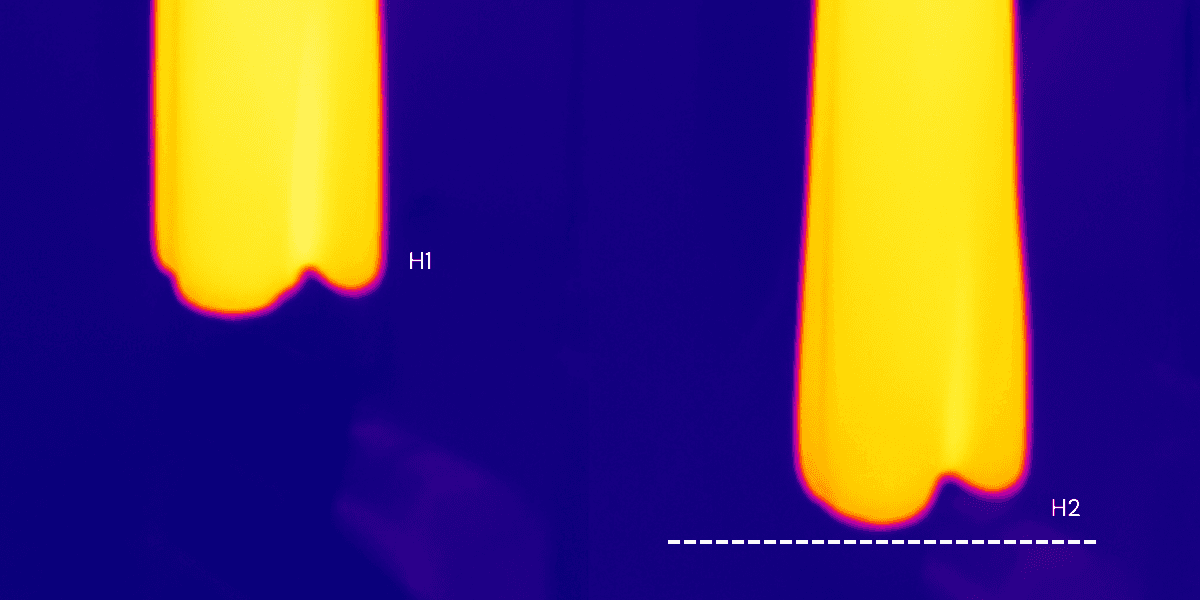

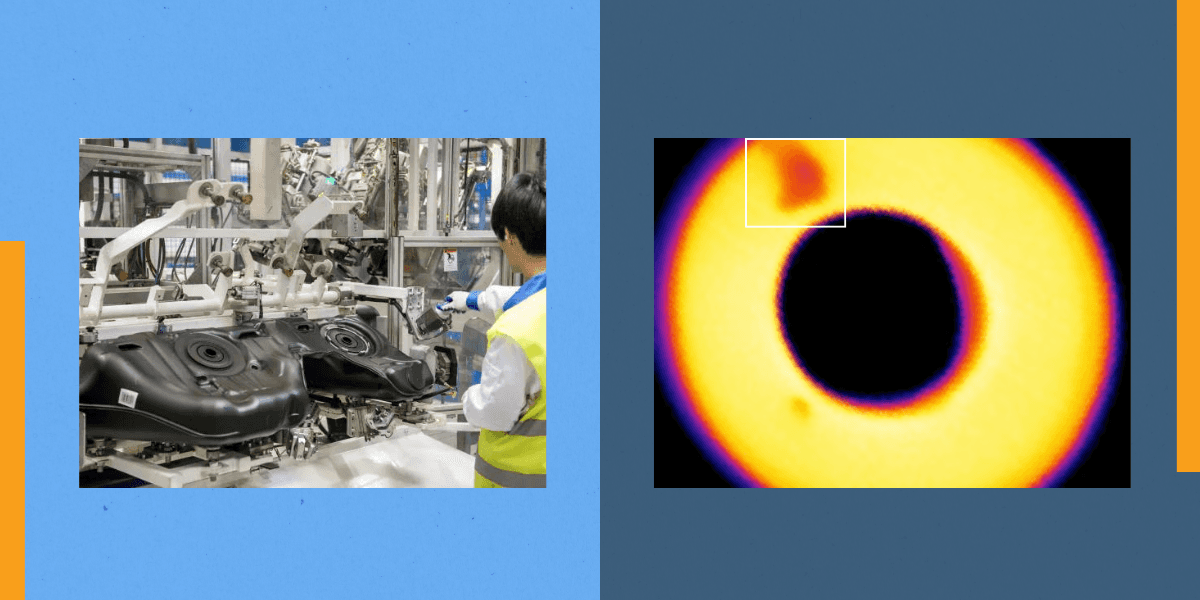

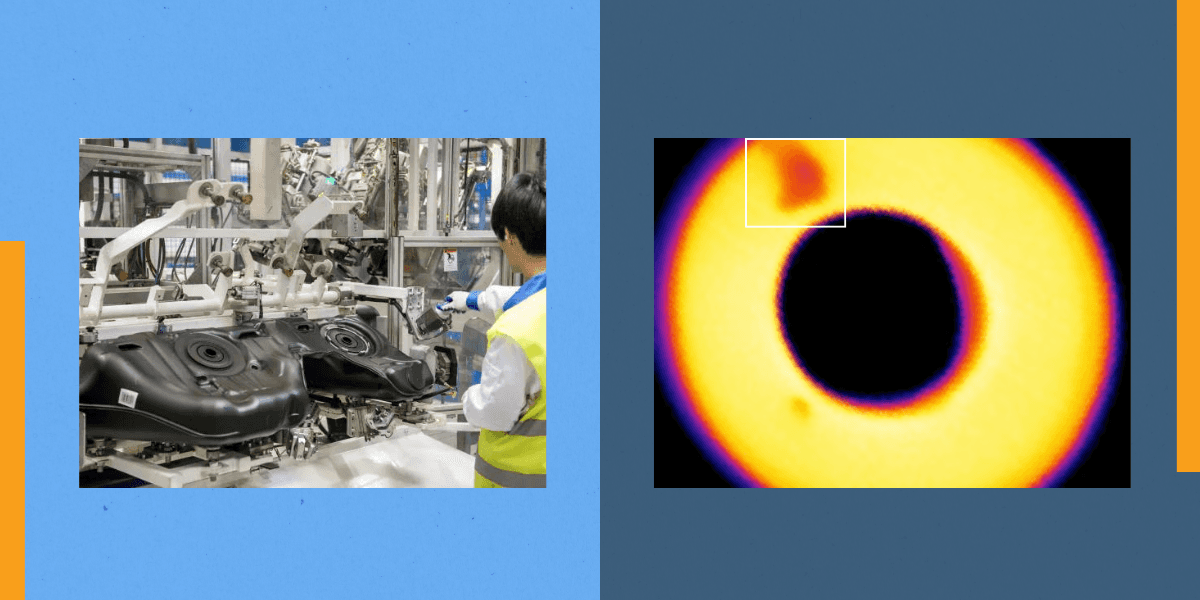

Operator view vs Eigen view

A side-by-side look at how Eigen’s thermal vision system reveals hidden weld defects invisible to the naked eye.

Benefits

In-Process Detection: Identifies welding defects as they form, preventing defective parts from moving downstream.

Comprehensive Coverage: Detects multiple defect types - fusion, flatness, misalignment, or overheating, across the full weld seam.

Actionable Insights: Inspection data is processed in OneView Cloud, where operators can view severity scores, defect locations, and trend data for continuous quality optimization.

Consistent Quality: AI-driven alarming and thresholds ensure uniform weld strength and integrity across production lines.

Scalable & Efficient: Once trained, inspection models can be replicated across new lines, reducing setup time and engineering effort.

The Challenge

In hot plate plastic welding, defects like incomplete fusion, misalignment, overheating, or weak bonds can occur due to warped geometry, uneven contact, or inconsistent heating. Traditional inspection methods rely on post-process sampling, which makes it difficult to catch defects in real time.These undetected issues can lead to part failures, costly rework, and warranty claims. As production speed and complexity increase, manufacturers need a faster, more reliable way to ensure every weld meets specification.

Our Solution

Eigen’s AI-powered thermal inspection system detects and classifies weld quality issues in-line, directly during the welding stage.Thermal cameras track temperature distribution, flatness, and fusion patterns across the weld perimeter, while AI models identify anomalies that signal weak or incomplete bonds.

Inspection data is processed in OneView Cloud, where operators can view severity scores, defect locations, and trend data for root-cause analysis. The system connects with the line’s PLC to trigger alarms or light stacks, allowing for immediate corrective action without halting production.

With configurable, customer-defined quality thresholds, engineers can fine-tune process parameters in real time and continuously improve weld consistency across multiple lines.

Operator view vs Eigen view

A side-by-side look at how Eigen’s thermal vision system reveals hidden weld defects invisible to the naked eye.

Benefits

In-Process Detection: Identifies welding defects as they form, preventing defective parts from moving downstream.

Comprehensive Coverage: Detects multiple defect types - fusion, flatness, misalignment, or overheating, across the full weld seam.

Actionable Insights: Inspection data is processed in OneView Cloud, where operators can view severity scores, defect locations, and trend data for continuous quality optimization.

Consistent Quality: AI-driven alarming and thresholds ensure uniform weld strength and integrity across production lines.

Scalable & Efficient: Once trained, inspection models can be replicated across new lines, reducing setup time and engineering effort.

The Challenge

In hot plate plastic welding, defects like incomplete fusion, misalignment, overheating, or weak bonds can occur due to warped geometry, uneven contact, or inconsistent heating. Traditional inspection methods rely on post-process sampling, which makes it difficult to catch defects in real time.These undetected issues can lead to part failures, costly rework, and warranty claims. As production speed and complexity increase, manufacturers need a faster, more reliable way to ensure every weld meets specification.

Our Solution

Eigen’s AI-powered thermal inspection system detects and classifies weld quality issues in-line, directly during the welding stage.Thermal cameras track temperature distribution, flatness, and fusion patterns across the weld perimeter, while AI models identify anomalies that signal weak or incomplete bonds.

Inspection data is processed in OneView Cloud, where operators can view severity scores, defect locations, and trend data for root-cause analysis. The system connects with the line’s PLC to trigger alarms or light stacks, allowing for immediate corrective action without halting production.

With configurable, customer-defined quality thresholds, engineers can fine-tune process parameters in real time and continuously improve weld consistency across multiple lines.

Operator view vs Eigen view

A side-by-side look at how Eigen’s thermal vision system reveals hidden weld defects invisible to the naked eye.

Benefits

In-Process Detection: Identifies welding defects as they form, preventing defective parts from moving downstream.

Comprehensive Coverage: Detects multiple defect types - fusion, flatness, misalignment, or overheating, across the full weld seam.

Actionable Insights: Inspection data is processed in OneView Cloud, where operators can view severity scores, defect locations, and trend data for continuous quality optimization.

Consistent Quality: AI-driven alarming and thresholds ensure uniform weld strength and integrity across production lines.

Scalable & Efficient: Once trained, inspection models can be replicated across new lines, reducing setup time and engineering effort.

The Challenge

In hot plate plastic welding, defects like incomplete fusion, misalignment, overheating, or weak bonds can occur due to warped geometry, uneven contact, or inconsistent heating. Traditional inspection methods rely on post-process sampling, which makes it difficult to catch defects in real time.These undetected issues can lead to part failures, costly rework, and warranty claims. As production speed and complexity increase, manufacturers need a faster, more reliable way to ensure every weld meets specification.

Our Solution

Eigen’s AI-powered thermal inspection system detects and classifies weld quality issues in-line, directly during the welding stage.Thermal cameras track temperature distribution, flatness, and fusion patterns across the weld perimeter, while AI models identify anomalies that signal weak or incomplete bonds.

Inspection data is processed in OneView Cloud, where operators can view severity scores, defect locations, and trend data for root-cause analysis. The system connects with the line’s PLC to trigger alarms or light stacks, allowing for immediate corrective action without halting production.

With configurable, customer-defined quality thresholds, engineers can fine-tune process parameters in real time and continuously improve weld consistency across multiple lines.

Operator view vs Eigen view

A side-by-side look at how Eigen’s thermal vision system reveals hidden weld defects invisible to the naked eye.

Benefits

In-Process Detection: Identifies welding defects as they form, preventing defective parts from moving downstream.

Comprehensive Coverage: Detects multiple defect types - fusion, flatness, misalignment, or overheating, across the full weld seam.

Actionable Insights: Inspection data is processed in OneView Cloud, where operators can view severity scores, defect locations, and trend data for continuous quality optimization.

Consistent Quality: AI-driven alarming and thresholds ensure uniform weld strength and integrity across production lines.

Scalable & Efficient: Once trained, inspection models can be replicated across new lines, reducing setup time and engineering effort.

Read more

Hot Plate Weld Verification

Plastics

Real-time thermal inspection system that identifies weld defects as they form, ensuring stronger bonds and consistent product quality.

Download

Sheet

Solution

Hot Plate Weld Verification