Metals

Furnace Refractory Monitoring

Real-time thermal monitoring system that detects early refractory wear and heat leakage so teams can plan maintenance before safety risks, energy loss, or unplanned shutdowns occur.

The Challenge

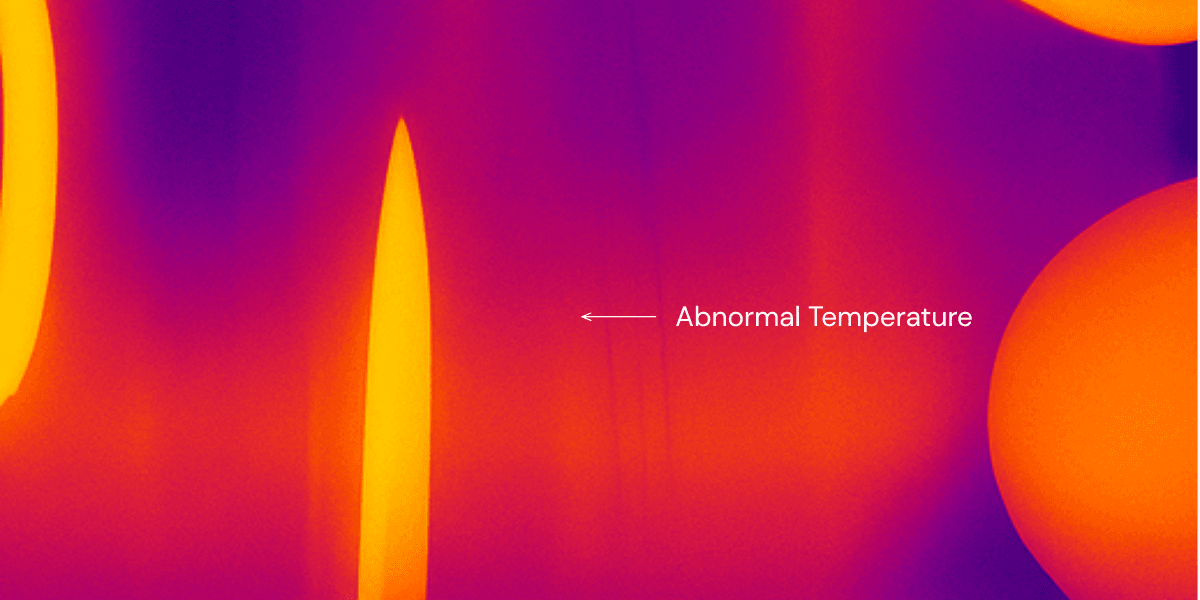

The refractory lining of a melt furnace naturally degrades over time due to extreme temperatures and thermal cycling. Early signs of wear often appear as abnormal heat leakage, hotspots, or uneven temperature patterns on the furnace’s exterior surface.

If left unchecked, refractory degradation can create unsafe operating conditions, increase energy loss, and drive unplanned shutdowns. Early detection gives maintenance teams time to schedule interventions and avoid failures.

Our Solution

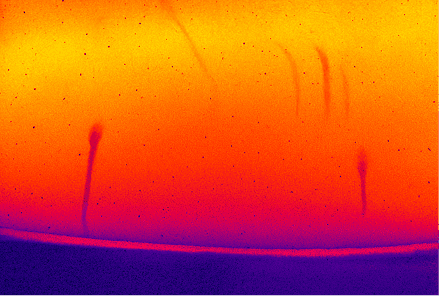

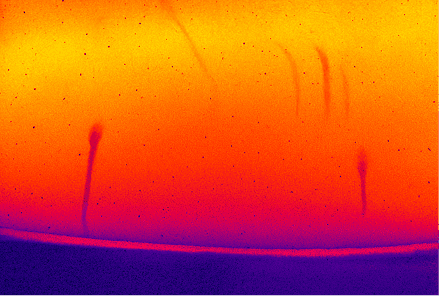

Eigen’s AI-powered refractory monitoring solution continuously analyzes the exterior thermal signature of the furnace to detect heat escaping through worn or thinning refractory areas. By monitoring temperature distribution along the furnace wall, OneView identifies deviations from normal operating patterns that may indicate degradation, cracking, or insulation failure.

Thermal cameras positioned outside the refractory capture images continuously while OneView evaluates temperature behavior against learned baselines. When abnormal conditions are detected, operators receive instant alerts via the HMI or light stack, enabling proactive investigation and maintenance planning before issues worsen.

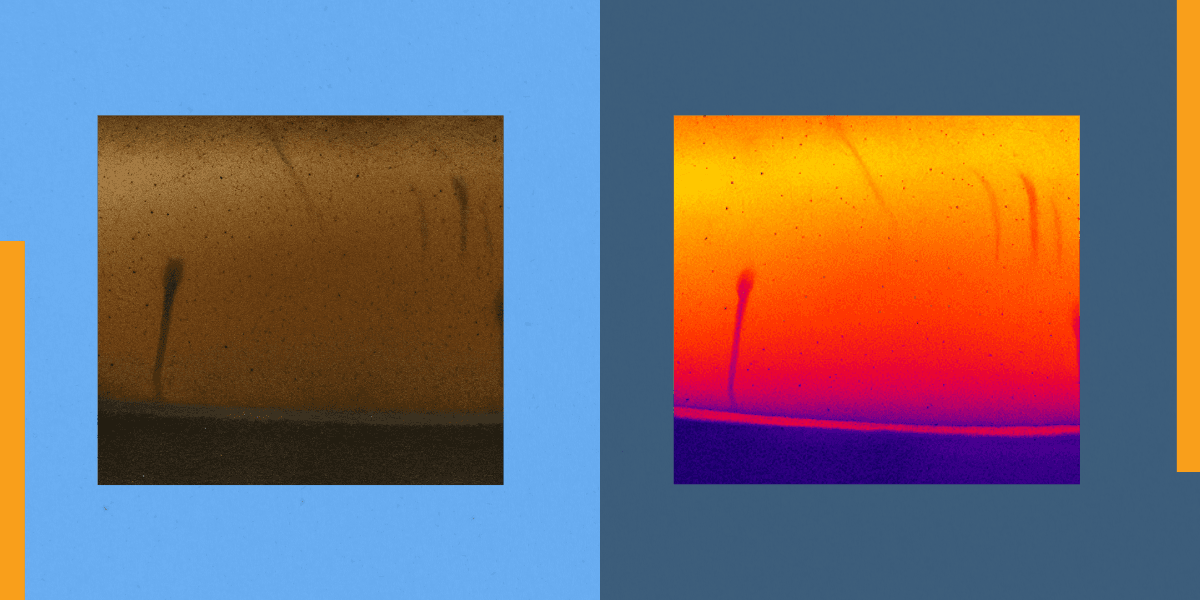

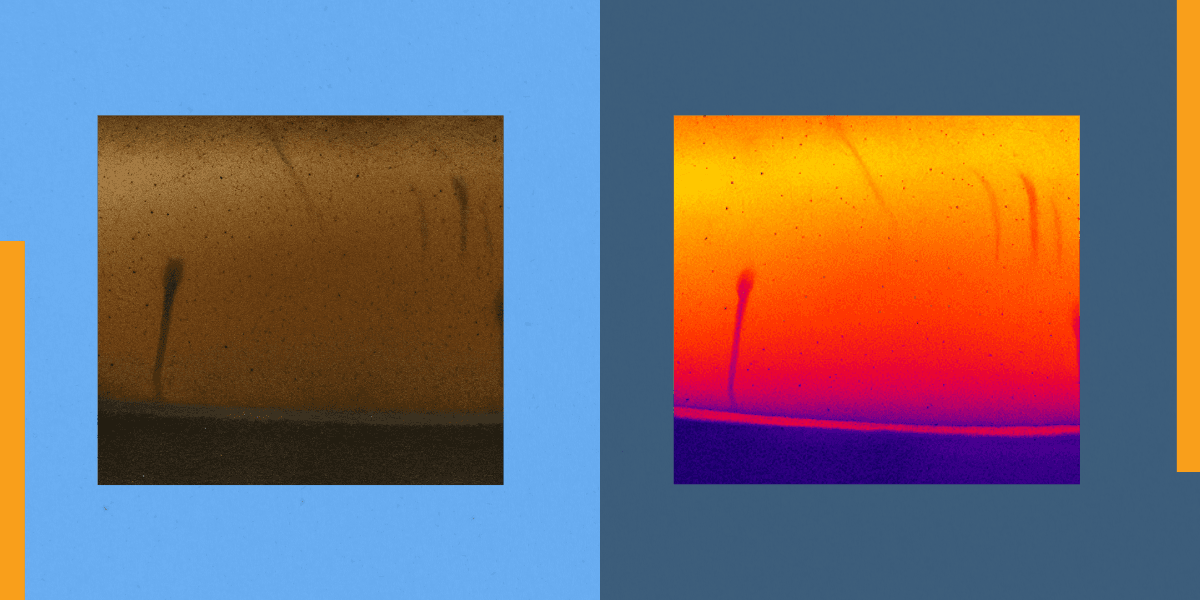

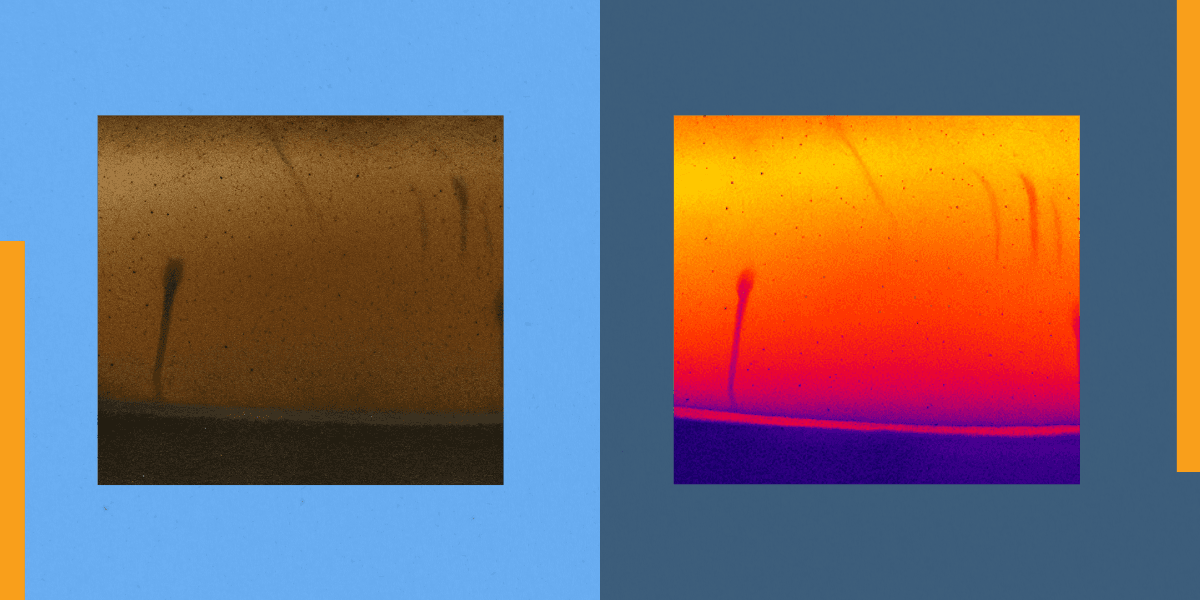

Operator view vs Eigen view

Optical view of the furnace exterior showing the refractory surface under normal operating conditions. Visual inspection alone makes it difficult to identify early-stage refractory wear, internal heat leakage, or subtle insulation breakdown.

Benefits

Earlier Detection of Refractory Wear: Identifies heat leakage patterns that may indicate thinning refractory, cracking, or insulation failure.

Reduced Energy Loss: Helps prevent prolonged heat leakage that increases fuel consumption and reduces furnace efficiency.

Proactive Maintenance Planning: Tracks degradation trends over time so teams can prioritize repairs before failures occur.

Clear Temperature State Classification: Classifies conditions as Normal Temperature, Abnormal Temperature, or Fault for fast decision-making.

Real-Time Alerts: Notifies operators immediately when thermal patterns require investigation, reducing response time and risk.

Improved Safety and Uptime: Supports safer furnace operation and helps avoid unplanned shutdowns caused by refractory failures.

The Challenge

The refractory lining of a melt furnace naturally degrades over time due to extreme temperatures and thermal cycling. Early signs of wear often appear as abnormal heat leakage, hotspots, or uneven temperature patterns on the furnace’s exterior surface.

If left unchecked, refractory degradation can create unsafe operating conditions, increase energy loss, and drive unplanned shutdowns. Early detection gives maintenance teams time to schedule interventions and avoid failures.

Our Solution

Eigen’s AI-powered refractory monitoring solution continuously analyzes the exterior thermal signature of the furnace to detect heat escaping through worn or thinning refractory areas. By monitoring temperature distribution along the furnace wall, OneView identifies deviations from normal operating patterns that may indicate degradation, cracking, or insulation failure.

Thermal cameras positioned outside the refractory capture images continuously while OneView evaluates temperature behavior against learned baselines. When abnormal conditions are detected, operators receive instant alerts via the HMI or light stack, enabling proactive investigation and maintenance planning before issues worsen.

Operator view vs Eigen view

Optical view of the furnace exterior showing the refractory surface under normal operating conditions. Visual inspection alone makes it difficult to identify early-stage refractory wear, internal heat leakage, or subtle insulation breakdown.

Benefits

Earlier Detection of Refractory Wear: Identifies heat leakage patterns that may indicate thinning refractory, cracking, or insulation failure.

Reduced Energy Loss: Helps prevent prolonged heat leakage that increases fuel consumption and reduces furnace efficiency.

Proactive Maintenance Planning: Tracks degradation trends over time so teams can prioritize repairs before failures occur.

Clear Temperature State Classification: Classifies conditions as Normal Temperature, Abnormal Temperature, or Fault for fast decision-making.

Real-Time Alerts: Notifies operators immediately when thermal patterns require investigation, reducing response time and risk.

Improved Safety and Uptime: Supports safer furnace operation and helps avoid unplanned shutdowns caused by refractory failures.

The Challenge

The refractory lining of a melt furnace naturally degrades over time due to extreme temperatures and thermal cycling. Early signs of wear often appear as abnormal heat leakage, hotspots, or uneven temperature patterns on the furnace’s exterior surface.

If left unchecked, refractory degradation can create unsafe operating conditions, increase energy loss, and drive unplanned shutdowns. Early detection gives maintenance teams time to schedule interventions and avoid failures.

Our Solution

Eigen’s AI-powered refractory monitoring solution continuously analyzes the exterior thermal signature of the furnace to detect heat escaping through worn or thinning refractory areas. By monitoring temperature distribution along the furnace wall, OneView identifies deviations from normal operating patterns that may indicate degradation, cracking, or insulation failure.

Thermal cameras positioned outside the refractory capture images continuously while OneView evaluates temperature behavior against learned baselines. When abnormal conditions are detected, operators receive instant alerts via the HMI or light stack, enabling proactive investigation and maintenance planning before issues worsen.

Operator view vs Eigen view

Optical view of the furnace exterior showing the refractory surface under normal operating conditions. Visual inspection alone makes it difficult to identify early-stage refractory wear, internal heat leakage, or subtle insulation breakdown.

Benefits

Earlier Detection of Refractory Wear: Identifies heat leakage patterns that may indicate thinning refractory, cracking, or insulation failure.

Reduced Energy Loss: Helps prevent prolonged heat leakage that increases fuel consumption and reduces furnace efficiency.

Proactive Maintenance Planning: Tracks degradation trends over time so teams can prioritize repairs before failures occur.

Clear Temperature State Classification: Classifies conditions as Normal Temperature, Abnormal Temperature, or Fault for fast decision-making.

Real-Time Alerts: Notifies operators immediately when thermal patterns require investigation, reducing response time and risk.

Improved Safety and Uptime: Supports safer furnace operation and helps avoid unplanned shutdowns caused by refractory failures.

The Challenge

The refractory lining of a melt furnace naturally degrades over time due to extreme temperatures and thermal cycling. Early signs of wear often appear as abnormal heat leakage, hotspots, or uneven temperature patterns on the furnace’s exterior surface.

If left unchecked, refractory degradation can create unsafe operating conditions, increase energy loss, and drive unplanned shutdowns. Early detection gives maintenance teams time to schedule interventions and avoid failures.

Our Solution

Eigen’s AI-powered refractory monitoring solution continuously analyzes the exterior thermal signature of the furnace to detect heat escaping through worn or thinning refractory areas. By monitoring temperature distribution along the furnace wall, OneView identifies deviations from normal operating patterns that may indicate degradation, cracking, or insulation failure.

Thermal cameras positioned outside the refractory capture images continuously while OneView evaluates temperature behavior against learned baselines. When abnormal conditions are detected, operators receive instant alerts via the HMI or light stack, enabling proactive investigation and maintenance planning before issues worsen.

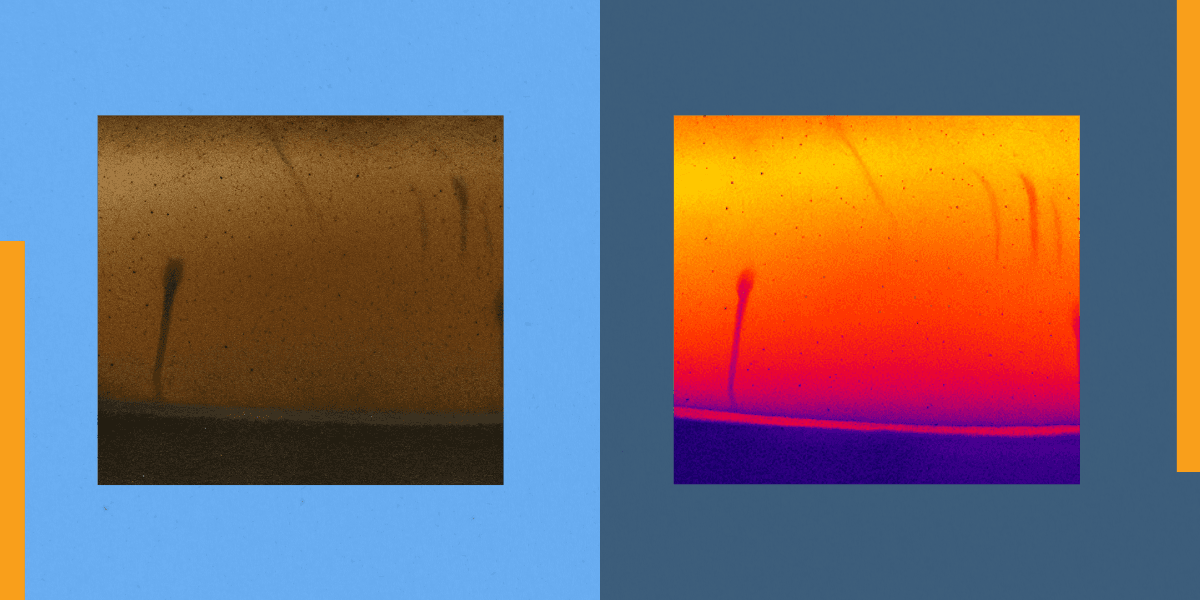

Operator view vs Eigen view

Optical view of the furnace exterior showing the refractory surface under normal operating conditions. Visual inspection alone makes it difficult to identify early-stage refractory wear, internal heat leakage, or subtle insulation breakdown.

Benefits

Earlier Detection of Refractory Wear: Identifies heat leakage patterns that may indicate thinning refractory, cracking, or insulation failure.

Reduced Energy Loss: Helps prevent prolonged heat leakage that increases fuel consumption and reduces furnace efficiency.

Proactive Maintenance Planning: Tracks degradation trends over time so teams can prioritize repairs before failures occur.

Clear Temperature State Classification: Classifies conditions as Normal Temperature, Abnormal Temperature, or Fault for fast decision-making.

Real-Time Alerts: Notifies operators immediately when thermal patterns require investigation, reducing response time and risk.

Improved Safety and Uptime: Supports safer furnace operation and helps avoid unplanned shutdowns caused by refractory failures.

Read more

Furnace Refractory Monitoring

Metals

Real-time thermal monitoring system that detects early refractory wear and heat leakage so teams can plan maintenance before safety risks, energy loss, or unplanned shutdowns occur.

Download

Sheet

Solution

Furnace Refractory Monitoring