Metals

Steel Grating Weld Inspection

Our real-time inspections lets operators fix issues instantly, ensuring weld safety and durability while reducing rework and waste.

The Challenge

Steel grate welding requires precise control to maintain structural integrity, load-bearing performance, and long-term durability. But verifying weld quality in-line is difficult. Many defects, such as blow-outs, misaligned welds, cold welds, missing bars, bent or twisted bars, and irregular spacing between bearing bars, are hard to see with the human eye.

Manual inspection methods rely heavily on subjective judgment and can miss subtle thermal variations that reveal weak joints or incomplete fusion. Undetected flaws can lead to recalls, costly scrap, rework, and in severe cases, safety risks for end users.

Our Solution

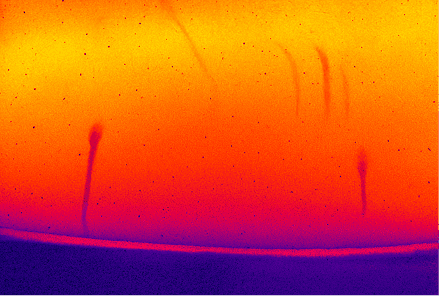

Eigen’s AI-powered thermal inspection system captures and analyzes the heat signatures of each weld as grating is produced.

Thermal cameras mounted on the welding line collect continuous thermal imagery and process data. These images are transformed into detailed thermal profiles of every weld. Within OneView, trained AI models analyze these profiles in real time to detect abnormal temperature gradients, cold joints, overheating, or other deviations from standard weld patterns.

When a defect is detected, OneView alerts operators immediately so they can correct the issue before defective grating is shipped. The system also aggregates weld and thermal data over time, giving teams insight into equipment performance, process stability, and areas for improvement.

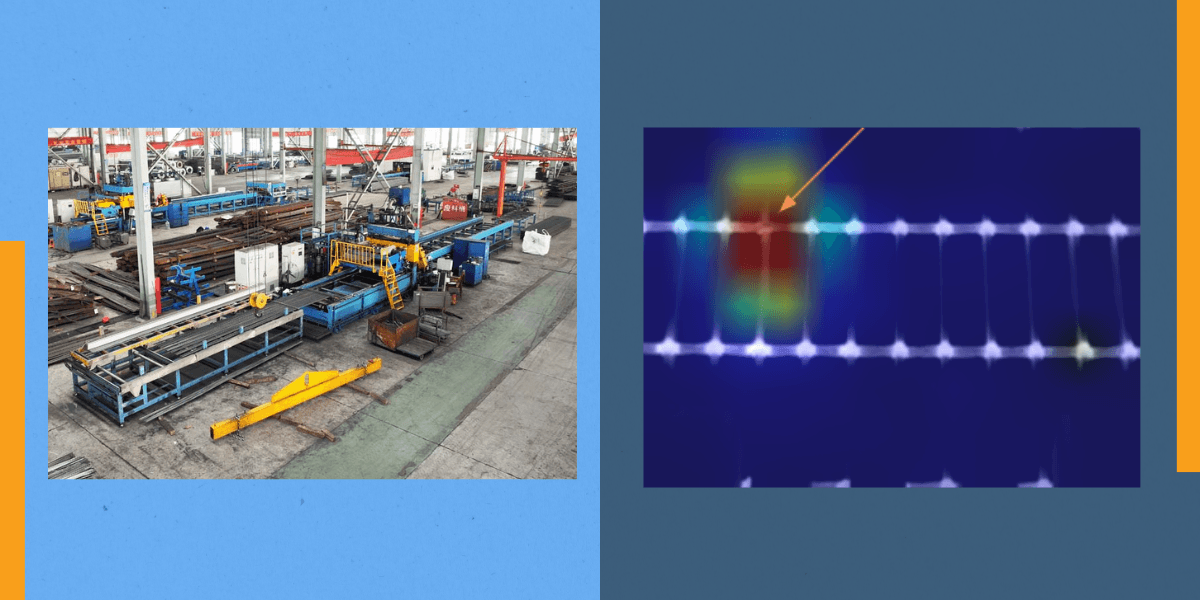

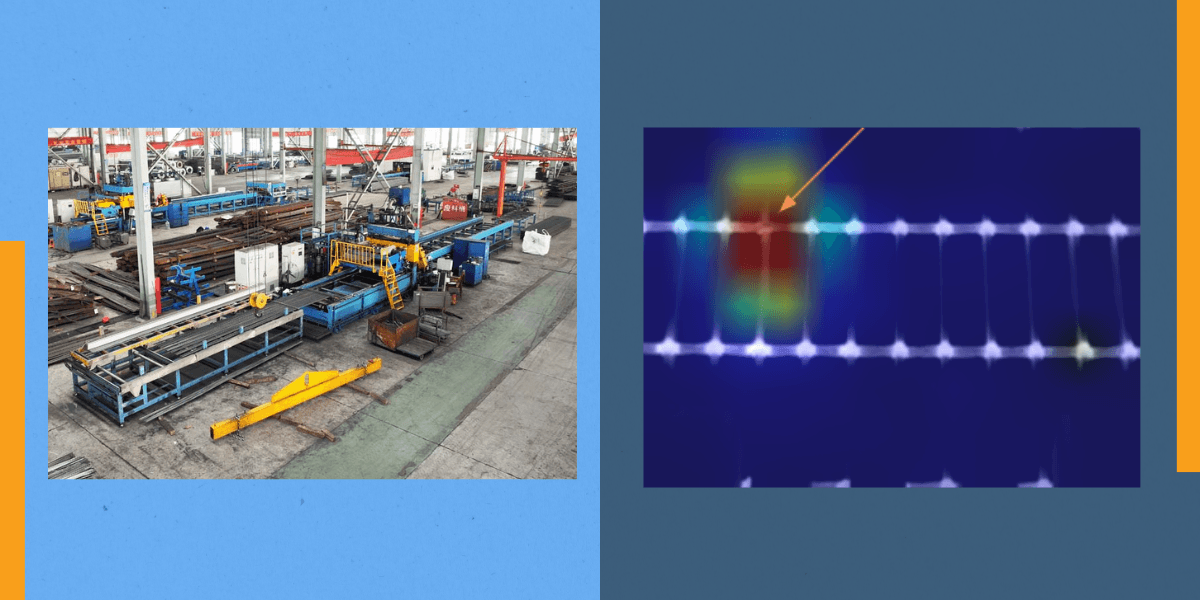

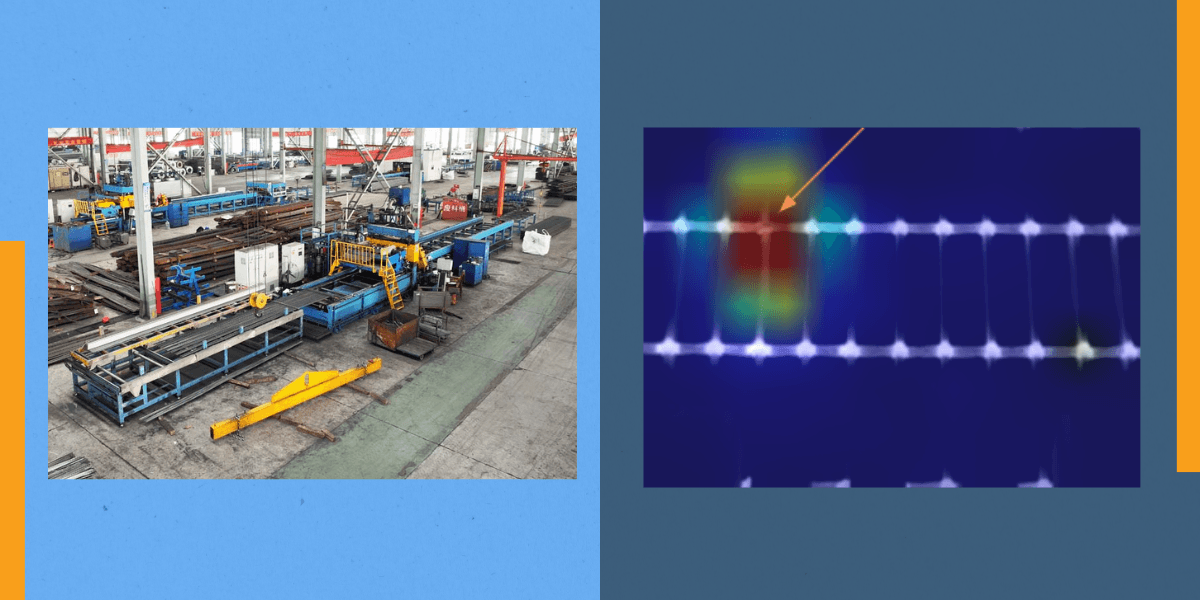

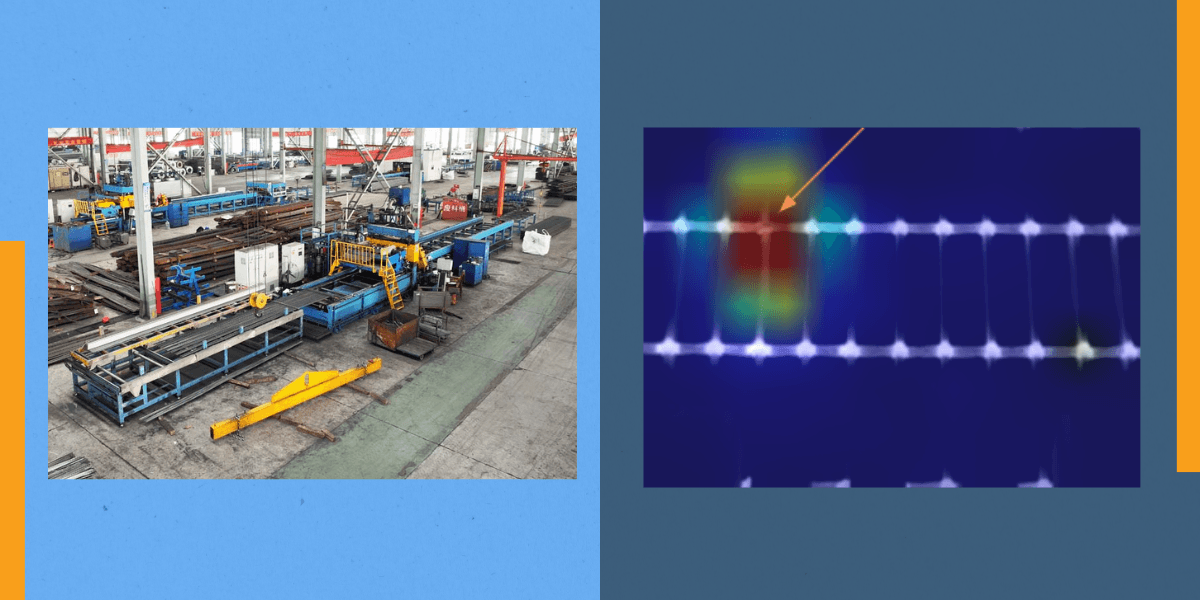

Operator view vs Eigen view

Benefits

Thermal Weld Visibility – See weld quality in a way traditional cameras cannot. OneView visualizes the full heat profile of every weld, making weak fusion, incomplete joints, and cold welds immediately visible so nothing gets missed.

Real-Time Alerts – Operators are notified the moment weld temperatures drift from normal ranges, enabling quick adjustments before issues escalate across a batch.

Automatic Quality Records – Creates a full digital log of every weld, helping manufacturers prove quality, support audits, and maintain consistent traceability.

Process Health Monitoring – Continuous thermal data reveals early signs of machine drift, electrode wear, or alignment issues before they cause widespread defects, allowing teams to act proactively.

Consistent, Objective Inspection – AI models apply the same standard to every weld, eliminating subjectivity and ensuring consistent results across operators, shifts, and lines.

Reduced Scrap and Rework – Early detection of weld issues prevents defective grating from moving downstream, reducing waste, minimizing rework, and keeping production efficient.

The Challenge

Steel grate welding requires precise control to maintain structural integrity, load-bearing performance, and long-term durability. But verifying weld quality in-line is difficult. Many defects, such as blow-outs, misaligned welds, cold welds, missing bars, bent or twisted bars, and irregular spacing between bearing bars, are hard to see with the human eye.

Manual inspection methods rely heavily on subjective judgment and can miss subtle thermal variations that reveal weak joints or incomplete fusion. Undetected flaws can lead to recalls, costly scrap, rework, and in severe cases, safety risks for end users.

Our Solution

Eigen’s AI-powered thermal inspection system captures and analyzes the heat signatures of each weld as grating is produced.

Thermal cameras mounted on the welding line collect continuous thermal imagery and process data. These images are transformed into detailed thermal profiles of every weld. Within OneView, trained AI models analyze these profiles in real time to detect abnormal temperature gradients, cold joints, overheating, or other deviations from standard weld patterns.

When a defect is detected, OneView alerts operators immediately so they can correct the issue before defective grating is shipped. The system also aggregates weld and thermal data over time, giving teams insight into equipment performance, process stability, and areas for improvement.

Operator view vs Eigen view

Benefits

Thermal Weld Visibility – See weld quality in a way traditional cameras cannot. OneView visualizes the full heat profile of every weld, making weak fusion, incomplete joints, and cold welds immediately visible so nothing gets missed.

Real-Time Alerts – Operators are notified the moment weld temperatures drift from normal ranges, enabling quick adjustments before issues escalate across a batch.

Automatic Quality Records – Creates a full digital log of every weld, helping manufacturers prove quality, support audits, and maintain consistent traceability.

Process Health Monitoring – Continuous thermal data reveals early signs of machine drift, electrode wear, or alignment issues before they cause widespread defects, allowing teams to act proactively.

Consistent, Objective Inspection – AI models apply the same standard to every weld, eliminating subjectivity and ensuring consistent results across operators, shifts, and lines.

Reduced Scrap and Rework – Early detection of weld issues prevents defective grating from moving downstream, reducing waste, minimizing rework, and keeping production efficient.

The Challenge

Steel grate welding requires precise control to maintain structural integrity, load-bearing performance, and long-term durability. But verifying weld quality in-line is difficult. Many defects, such as blow-outs, misaligned welds, cold welds, missing bars, bent or twisted bars, and irregular spacing between bearing bars, are hard to see with the human eye.

Manual inspection methods rely heavily on subjective judgment and can miss subtle thermal variations that reveal weak joints or incomplete fusion. Undetected flaws can lead to recalls, costly scrap, rework, and in severe cases, safety risks for end users.

Our Solution

Eigen’s AI-powered thermal inspection system captures and analyzes the heat signatures of each weld as grating is produced.

Thermal cameras mounted on the welding line collect continuous thermal imagery and process data. These images are transformed into detailed thermal profiles of every weld. Within OneView, trained AI models analyze these profiles in real time to detect abnormal temperature gradients, cold joints, overheating, or other deviations from standard weld patterns.

When a defect is detected, OneView alerts operators immediately so they can correct the issue before defective grating is shipped. The system also aggregates weld and thermal data over time, giving teams insight into equipment performance, process stability, and areas for improvement.

Operator view vs Eigen view

Benefits

Thermal Weld Visibility – See weld quality in a way traditional cameras cannot. OneView visualizes the full heat profile of every weld, making weak fusion, incomplete joints, and cold welds immediately visible so nothing gets missed.

Real-Time Alerts – Operators are notified the moment weld temperatures drift from normal ranges, enabling quick adjustments before issues escalate across a batch.

Automatic Quality Records – Creates a full digital log of every weld, helping manufacturers prove quality, support audits, and maintain consistent traceability.

Process Health Monitoring – Continuous thermal data reveals early signs of machine drift, electrode wear, or alignment issues before they cause widespread defects, allowing teams to act proactively.

Consistent, Objective Inspection – AI models apply the same standard to every weld, eliminating subjectivity and ensuring consistent results across operators, shifts, and lines.

Reduced Scrap and Rework – Early detection of weld issues prevents defective grating from moving downstream, reducing waste, minimizing rework, and keeping production efficient.

The Challenge

Steel grate welding requires precise control to maintain structural integrity, load-bearing performance, and long-term durability. But verifying weld quality in-line is difficult. Many defects, such as blow-outs, misaligned welds, cold welds, missing bars, bent or twisted bars, and irregular spacing between bearing bars, are hard to see with the human eye.

Manual inspection methods rely heavily on subjective judgment and can miss subtle thermal variations that reveal weak joints or incomplete fusion. Undetected flaws can lead to recalls, costly scrap, rework, and in severe cases, safety risks for end users.

Our Solution

Eigen’s AI-powered thermal inspection system captures and analyzes the heat signatures of each weld as grating is produced.

Thermal cameras mounted on the welding line collect continuous thermal imagery and process data. These images are transformed into detailed thermal profiles of every weld. Within OneView, trained AI models analyze these profiles in real time to detect abnormal temperature gradients, cold joints, overheating, or other deviations from standard weld patterns.

When a defect is detected, OneView alerts operators immediately so they can correct the issue before defective grating is shipped. The system also aggregates weld and thermal data over time, giving teams insight into equipment performance, process stability, and areas for improvement.

Operator view vs Eigen view

Benefits

Thermal Weld Visibility – See weld quality in a way traditional cameras cannot. OneView visualizes the full heat profile of every weld, making weak fusion, incomplete joints, and cold welds immediately visible so nothing gets missed.

Real-Time Alerts – Operators are notified the moment weld temperatures drift from normal ranges, enabling quick adjustments before issues escalate across a batch.

Automatic Quality Records – Creates a full digital log of every weld, helping manufacturers prove quality, support audits, and maintain consistent traceability.

Process Health Monitoring – Continuous thermal data reveals early signs of machine drift, electrode wear, or alignment issues before they cause widespread defects, allowing teams to act proactively.

Consistent, Objective Inspection – AI models apply the same standard to every weld, eliminating subjectivity and ensuring consistent results across operators, shifts, and lines.

Reduced Scrap and Rework – Early detection of weld issues prevents defective grating from moving downstream, reducing waste, minimizing rework, and keeping production efficient.

Read more

Steel Grating Weld Inspection

Metals

Our real-time inspections lets operators fix issues instantly, ensuring weld safety and durability while reducing rework and waste.

Download

Sheet

Solution

Steel Grating Weld Inspection