Building Materials

Plastic Extrusion

Real-time monitoring and quality data help teams minimize or eliminate destructive testing, ensuring every product's structural integrity.

The Challenge

In plastic sheet and film extrusion, quality depends entirely on precise heating and cooling. Even small variations can create defects that compromise strength, flatness, or downstream performance.

Common issues such as voids, warp, uneven thickness, incomplete melt, and die lines often originate from inconsistent melt temperatures, cooling rates, or die imbalance.

Traditional tools like thermocouples provide only single-point measurements. They cannot show how heat is distributed across the width or along the length of the extrusion, which means critical defects remain hidden until later in production. Without a full thermal profile, operators lack the visibility needed to correct problems before scrap is produced.

Our Solution

Eigen’s AI-powered extrusion inspection system uses thermal imaging to capture thousands of temperature points simultaneously, generating a complete thermal map across the entire product as it exits the die.

By monitoring the full width and length of the extrusion, the system detects subtle variations in the thermal profile that signal voids, incomplete melt, cooling imbalance, or forming issues long before they become visible. Cold spots indicate potential air entrapment, while temperature gradients reveal cooling inconsistencies that lead to warp or internal stresses.

Alongside image data, OneView automatically collects key process parameters such as melt temperature, melt pressure, and line speed. Each sheet or film receives a unified digital record that links thermal images with process conditions. Machine learning models trained in OneView analyze this combined dataset in real time, flagging defects, identifying unusual patterns, and alerting operators before excessive non-conforming material is produced.

Quality and process teams use this data to understand trend shifts, stabilize production, and prevent recurring issues.

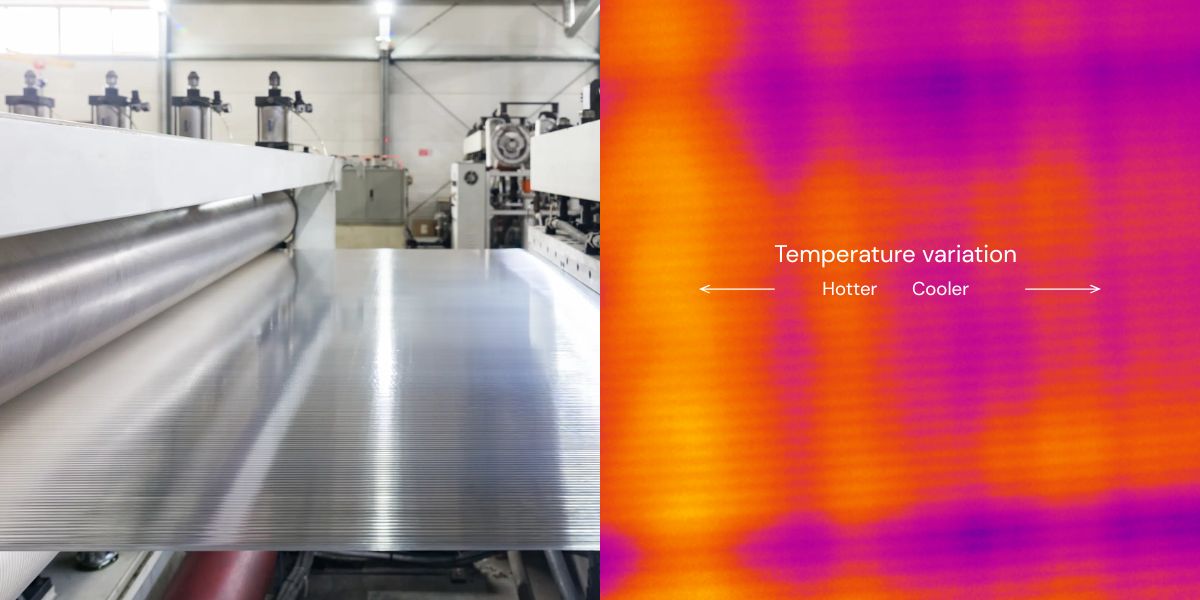

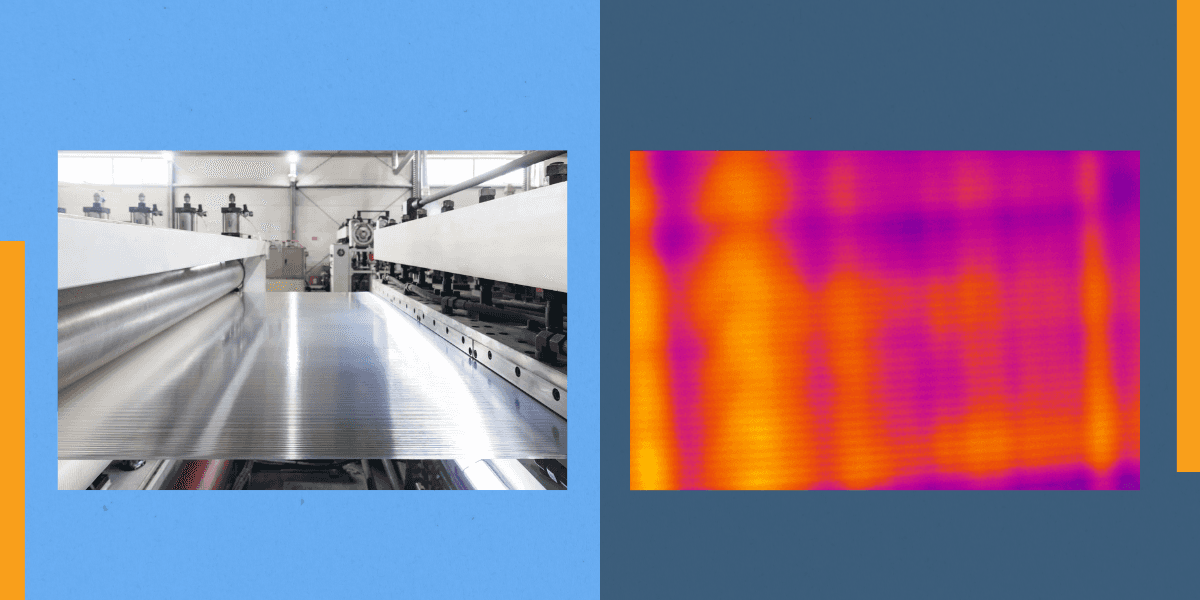

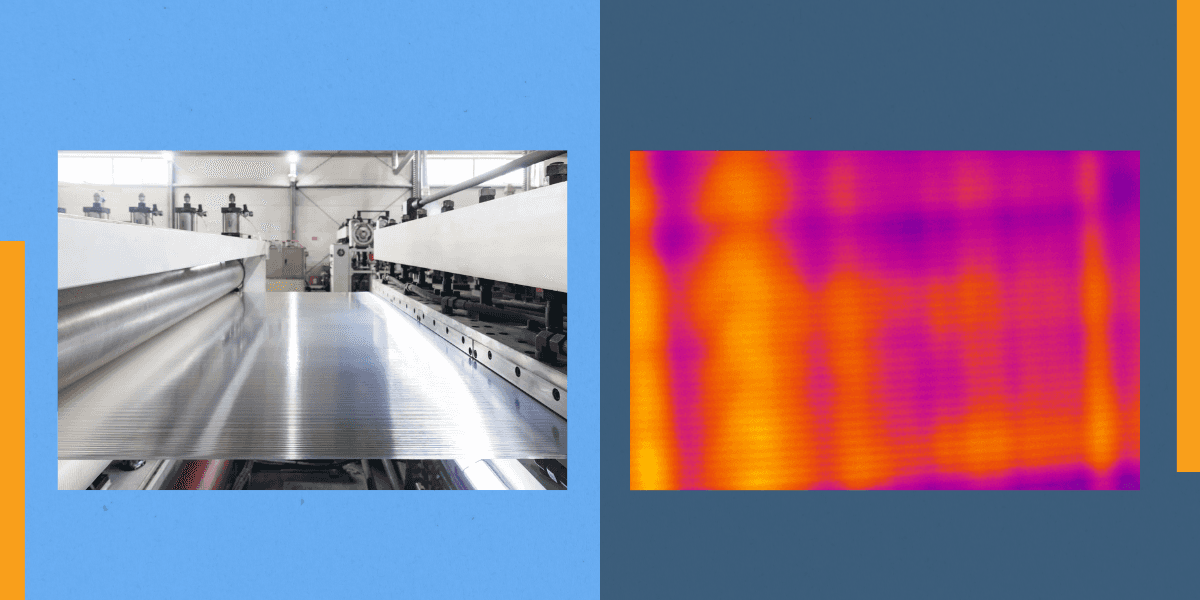

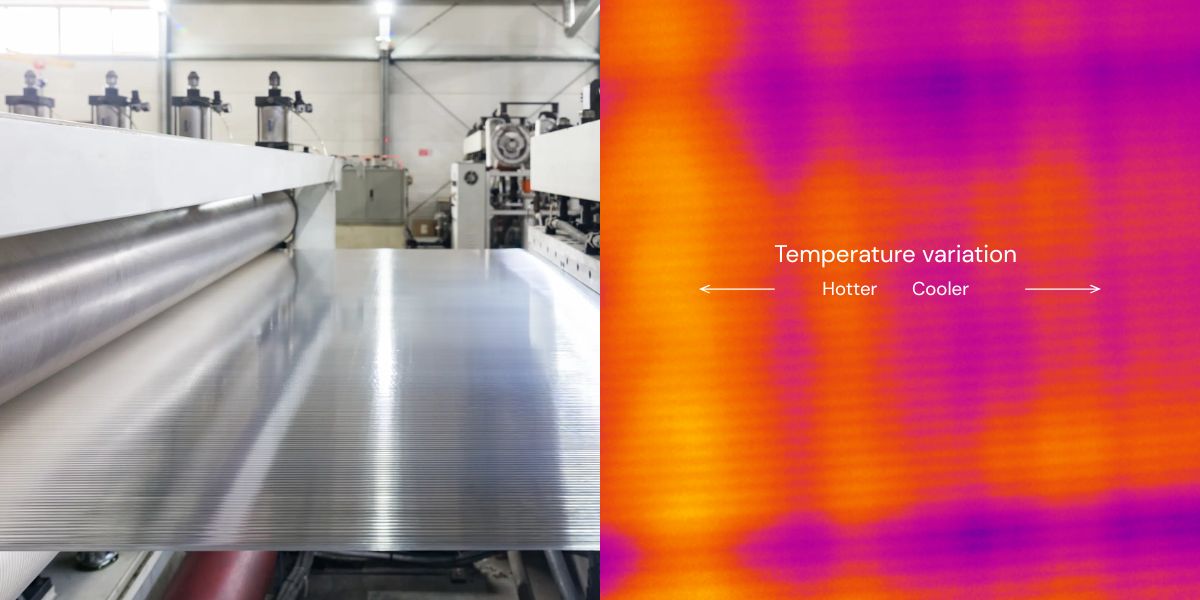

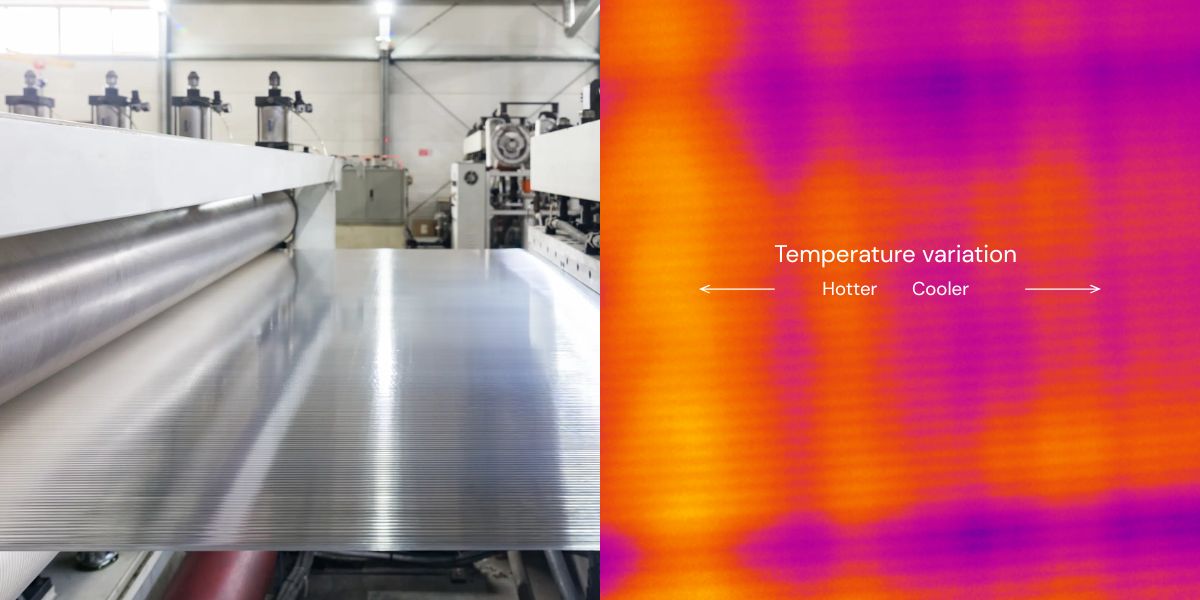

Operator view vs Eigen view

A side-by-side comparison of single-point thermocouple readings versus OneView’s complete thermal profile that clearly highlights die imbalance across the extrusion.

Benefits

Defect Detection and Classification - Identifies and classifies extrusion defects such as voids, warp, uneven thickness, incomplete melt, and die lines using full-field thermal imaging.

Integrated Process Data Capture - Links melt temperature, melt pressure, cycle time, line speed, and other key parameters with every thermal image to create a unified and traceable digital part record.

Real-Time Monitoring and Alerts - Detects anomalies as they occur and notifies operators immediately, enabling corrective action before defects propagate downstream.

Analytics and Insight Generation - Transforms thermal and process data into insights that reveal recurring issues, correlate defects with specific machine or material changes, and support long-term process optimization.

The Challenge

In plastic sheet and film extrusion, quality depends entirely on precise heating and cooling. Even small variations can create defects that compromise strength, flatness, or downstream performance.

Common issues such as voids, warp, uneven thickness, incomplete melt, and die lines often originate from inconsistent melt temperatures, cooling rates, or die imbalance.

Traditional tools like thermocouples provide only single-point measurements. They cannot show how heat is distributed across the width or along the length of the extrusion, which means critical defects remain hidden until later in production. Without a full thermal profile, operators lack the visibility needed to correct problems before scrap is produced.

Our Solution

Eigen’s AI-powered extrusion inspection system uses thermal imaging to capture thousands of temperature points simultaneously, generating a complete thermal map across the entire product as it exits the die.

By monitoring the full width and length of the extrusion, the system detects subtle variations in the thermal profile that signal voids, incomplete melt, cooling imbalance, or forming issues long before they become visible. Cold spots indicate potential air entrapment, while temperature gradients reveal cooling inconsistencies that lead to warp or internal stresses.

Alongside image data, OneView automatically collects key process parameters such as melt temperature, melt pressure, and line speed. Each sheet or film receives a unified digital record that links thermal images with process conditions. Machine learning models trained in OneView analyze this combined dataset in real time, flagging defects, identifying unusual patterns, and alerting operators before excessive non-conforming material is produced.

Quality and process teams use this data to understand trend shifts, stabilize production, and prevent recurring issues.

Operator view vs Eigen view

A side-by-side comparison of single-point thermocouple readings versus OneView’s complete thermal profile that clearly highlights die imbalance across the extrusion.

Benefits

Defect Detection and Classification - Identifies and classifies extrusion defects such as voids, warp, uneven thickness, incomplete melt, and die lines using full-field thermal imaging.

Integrated Process Data Capture - Links melt temperature, melt pressure, cycle time, line speed, and other key parameters with every thermal image to create a unified and traceable digital part record.

Real-Time Monitoring and Alerts - Detects anomalies as they occur and notifies operators immediately, enabling corrective action before defects propagate downstream.

Analytics and Insight Generation - Transforms thermal and process data into insights that reveal recurring issues, correlate defects with specific machine or material changes, and support long-term process optimization.

Plastic Extrusion

Building Materials

Real-time monitoring and quality data help teams minimize or eliminate destructive testing, ensuring every product's structural integrity.

Download

Sheet

Solution

Plastic Extrusion