A plastic HVAC duct leaves the welding cell looking perfect. Smooth bead, clean geometry, no visible defects. But months later, that same part ends up in a warranty claim for a small leak along the seam. This is one of the quiet truths about hot plate welding. The defects that matter most are often the ones nobody can see.

Hot plate welding is widely used across automotive and industrial plastics because it creates strong and repeatable joints. But the integrity of those joints depends entirely on the internal thermal behavior during welding. Heat distribution, melt temperature, penetration depth and uniform fusion determine long term performance. A weld can look good from the outside while hiding voids, shallow fusion or cold weld regions beneath the surface. According to a study presented at the QIRT Conference, early stage fusion defects in plastic welding often remain completely invisible under visual inspection and only become detectable once the part fails in service.

Why Traditional Inspection Is Not Enough

Traditional inspection methods including visual checks, dimensional measurements and occasional destructive testing are not designed to catch these hidden issues. Visual inspection is subjective and surface level. Destructive testing, while useful, covers only a tiny fraction of production.

Destructive weld verification often catches failures too late in the process and only on a small percent of total product. This makes it too reactive to protect manufacturers from escapes, especially when dealing with high volume components or safety related assemblies.

Why Temperature Tells the Truth

This is where thermal vision changes the equation. During hot plate welding the joint goes through a predictable heat cycle. The way heat rises, spreads and cools carries detailed information about weld integrity.

A study on inline thermography for plastic welds presented at QIRT showed that infrared inspection could detect subtle process deviations such as uneven heating or small drops in plate temperature well before visual inspection or pull tests indicated a problem. Heat patterns reveal the truth long before the part reaches the customer.

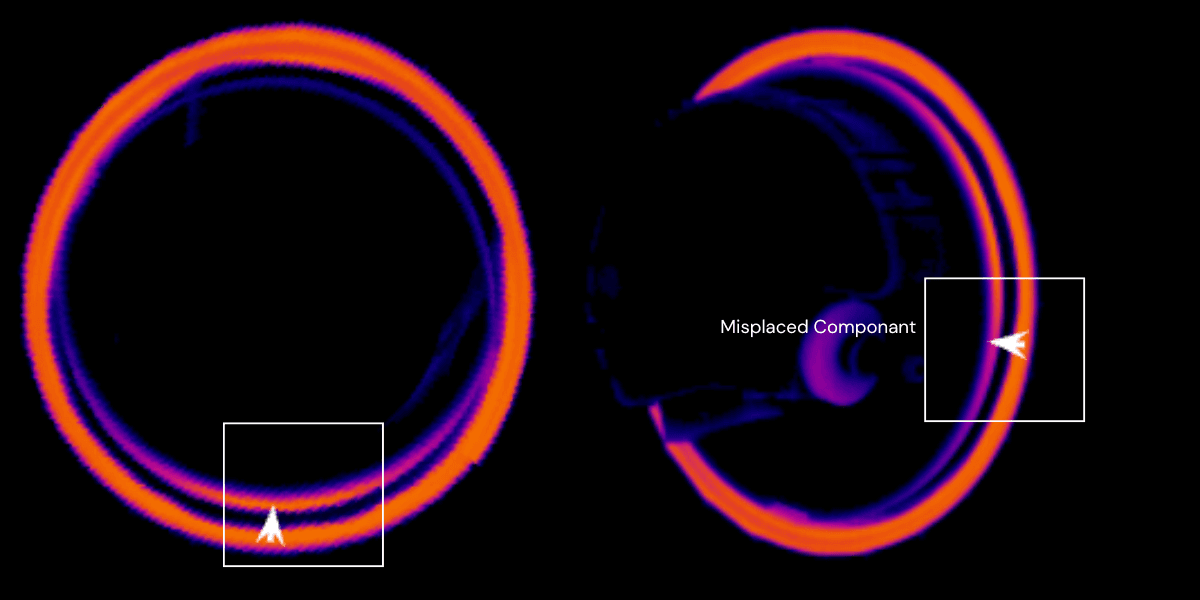

Thermal imaging captures this hidden layer in real time. Immediately after welding an infrared camera records the weld zone, generating a thermal fingerprint that reflects melt uniformity, heating consistency and material flow. According to a review published in Infrared Physics and Technology , thermography is uniquely effective for plastics because internal inconsistencies often alter thermal distribution without altering surface appearance. This makes it a powerful non destructive method for verifying whether heat truly reached where it needed to and whether the weld actually fused as intended.

How Thermal Verification Strengthens Quality

When combined with AI or automated analysis thermal verification becomes not only a diagnostic tool but a process stabilization tool. Instead of sampling a handful of parts destructively, manufacturers get full coverage inspection with real time alerts when the weld begins drifting out of its normal range.

Operators can correct issues immediately instead of discovering them at final inspection or through customer complaints. Because each weld can be logged with its thermal signature, teams gain traceability that visual checks could never provide. Thermal records offer clear, factual evidence of internal weld quality.

Why This Matters for Quality Engineers

For quality engineers the value is straightforward. Thermography makes the invisible visible. It turns weld verification from a reactive, surface level activity into a complete, data driven process. It looks good with real evidence of internal weld quality. This reduces returns, improves long term reliability and builds confidence across every shift and line.

At Eigen we build thermal and AI inspection systems that make this level of insight possible on real production lines. By capturing the full thermal signature of every weld and analyzing it in real time, manufacturers gain the consistency, traceability and early warning signals they need to keep quality stable.